VR Glass pcb | VR Glass Rigid Flex PCB | Virtual Reality Glass Circuit Board

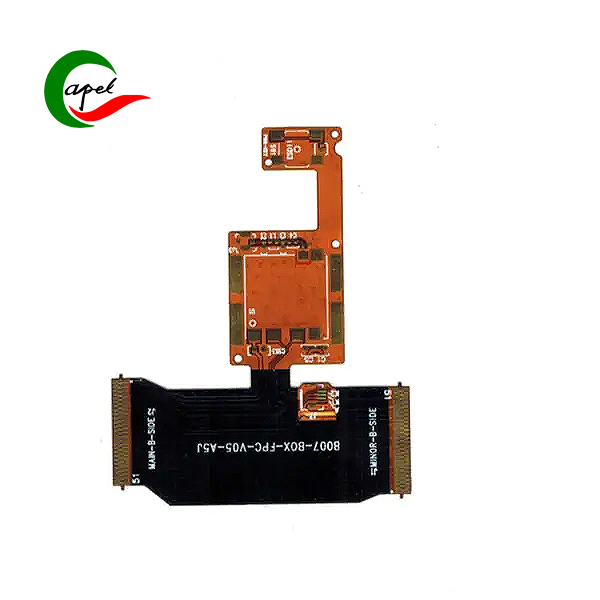

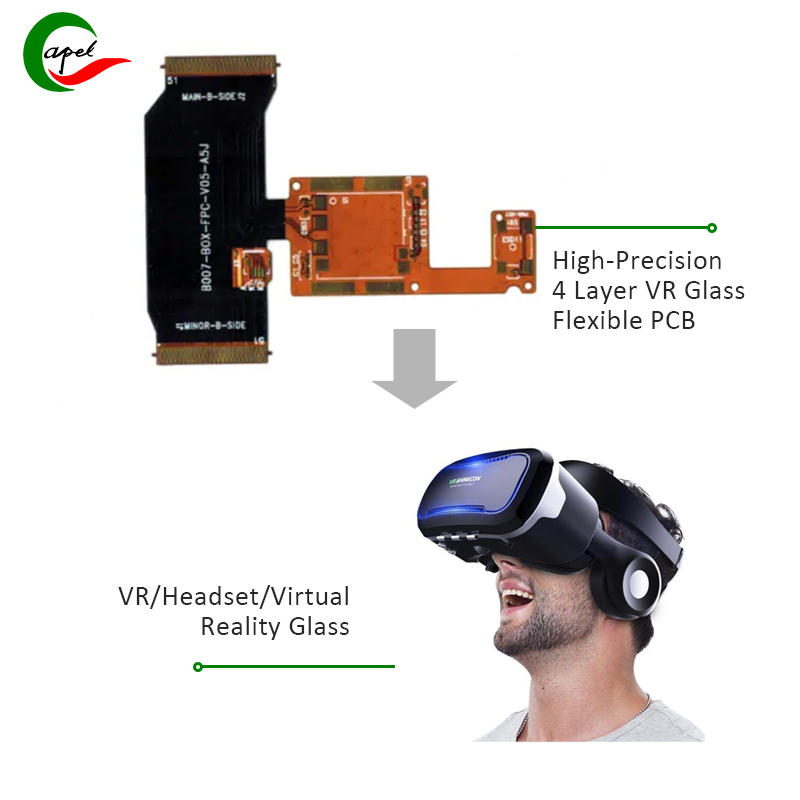

High-precision 4-layer flexible PCB, specially designed to provide reliable and efficient solutions for VR virtual reality glasses.

-Capel with 15 years of professional technical experience-

Introducing our high-precision 4-layer flexible PCB, specially designed to provide reliable and efficient solutions for VR virtual reality glasses. This cutting-edge product is ideal for gaming consoles and other applications that require flexible and durable printed circuit boards.

Our 4-layer flexible PCB is made from high-quality materials such as PI, copper and adhesives, ensuring a strong and resilient foundation for your electronic devices. The advanced materials used in the PCB construction ensure long-lasting durability and high performance, making it a perfect choice for VR glasses and other gaming applications.

Our 4-layer flexible PCBs feature 0.1mm/0.1mm line widths and spacing, providing extremely precise and precise connections for seamless communication between components. This level of accuracy is critical to the functionality and performance of VR headsets, ensuring a smooth, immersive gaming experience.

The board thickness of 0.26mm+/-0.03mm increases the durability and reliability of the 4-layer Flex PCB, providing a solid platform for the complex circuits required for VR virtual reality glasses. Additionally, the minimum aperture diameter of 0.1 mm further demonstrates the attention to detail and precision engineering that goes into the production of this high-quality PCB.

In terms of surface treatment, our 4-layer flexible PCB uses ENIG 2-3uin for surface treatment, which provides a protective and conductive layer to improve the performance and service life of the product. This surface treatment is critical to ensure PCB reliability and stability in demanding applications such as VR headsets.

One of the key features of our 4-layer flex PCB is its impedance tolerance of /, which allows for consistent and reliable signal transmission in VR glasses and game consoles. This precision is critical to maintaining electrical signal integrity and ensuring a seamless gaming experience for the end user.

Our 4-layer flex PCBs have a tolerance of ±0.1mm and are manufactured to the highest quality and precision standards. This level of accuracy is critical for VR headsets to function properly, as even the smallest deviation can impact performance.

Overall, our 4-layer flexible PCB is a perfect solution for VR virtual reality glasses and game consoles, providing high-precision structure and advanced features to ensure optimal performance and durability. When it comes to reliable, efficient PCB solutions for gaming applications, our 4-layer flexible PCBs are the perfect choice.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

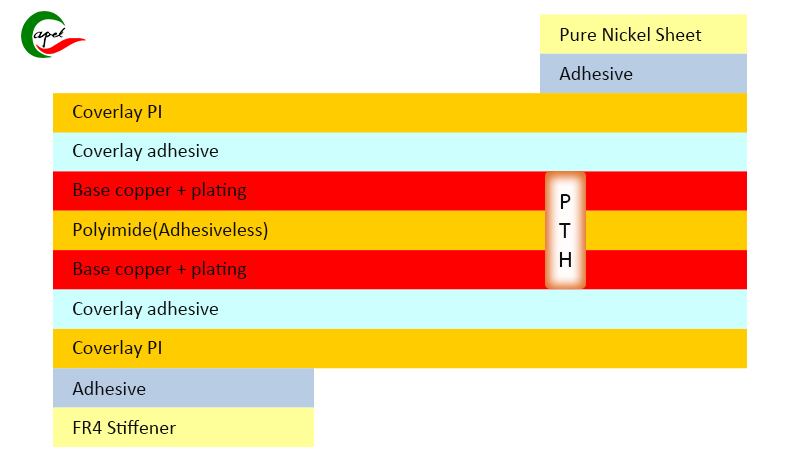

2 Layer Flexible PCB Boards Stackup

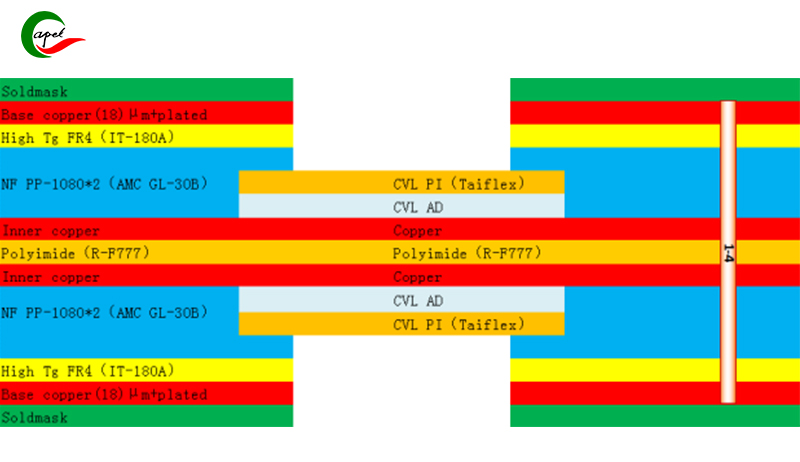

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.