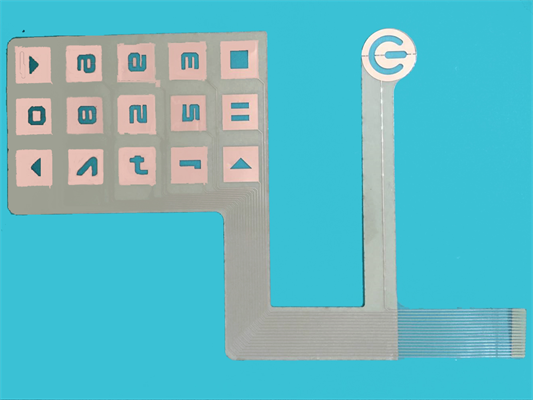

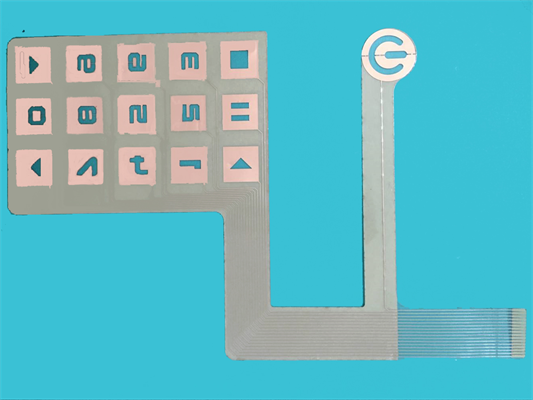

PET Key Board PCB | Transparent PCB | Clear Flexible PCB | Transparent Circuit Board

PET Key Board PCB | Transparent PCB | Clear Flexible PCB | Transparent Circuit Board

Flexible PET key board PCB brings many innovations and upgrades to the PET key board industry:

Flexibility: Flexible PET keyboard PCB allows greater design flexibility to create curved or irregularly shaped keyboards, thereby enhancing the overall aesthetics and ergonomics of the product.

Durability: PET material has excellent durability and wear resistance, making the keyboard more sturdy and durable. This improves product reliability and customer satisfaction.

Miniaturization: Flexible PCB's line width and spacing of 0.15mm/0.15mm enable the creation of smaller, more compact keyboards, allowing for more functionality in a smaller form factor.

Enhanced user experience: The 0.13mm sheet thickness, coupled with the smooth surface treatment of 2-3uin ENIG (electroless nickel plating), helps create a stylish and low-profile keyboard design, providing users with a more pleasant tactile experience. .

Manufacturing Accuracy: Tight tolerances of ±0.1mm ensure precision and consistency in PCB production, resulting in better key switch alignment and improved overall product performance.

Environmental Sustainability: As a recyclable material, PET offers a greener option for keyboard PCBs. The use of flexible PET reduces reliance on traditional rigid materials, helping to reduce e-waste and promote a more sustainable product life cycle.

Cost-Effectiveness: The manufacturing process of flexible PET key board PCB is more efficient and cost-effective compared to traditional rigid PCB. The material's flexibility could streamline the production process, potentially reducing manufacturing time and costs.

Another major advantage of using flexible PET keyboard PCBs is their excellent resistance to shock and vibration. PET's flexible properties allow PCBs to absorb shock and vibration, making them more durable in a variety of applications, especially those subject to movement or mechanical stress. This enhanced durability can extend product life and reduce failure rates, resulting in cost savings for manufacturers and increased reliability for end users.

In addition, the flexibility of PET keyboard PCB allows it to adapt to irregular shapes and fit into small spaces, providing more design flexibility for electronic devices. This is particularly beneficial for applications where space is limited, allowing for more compact and lightweight designs.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

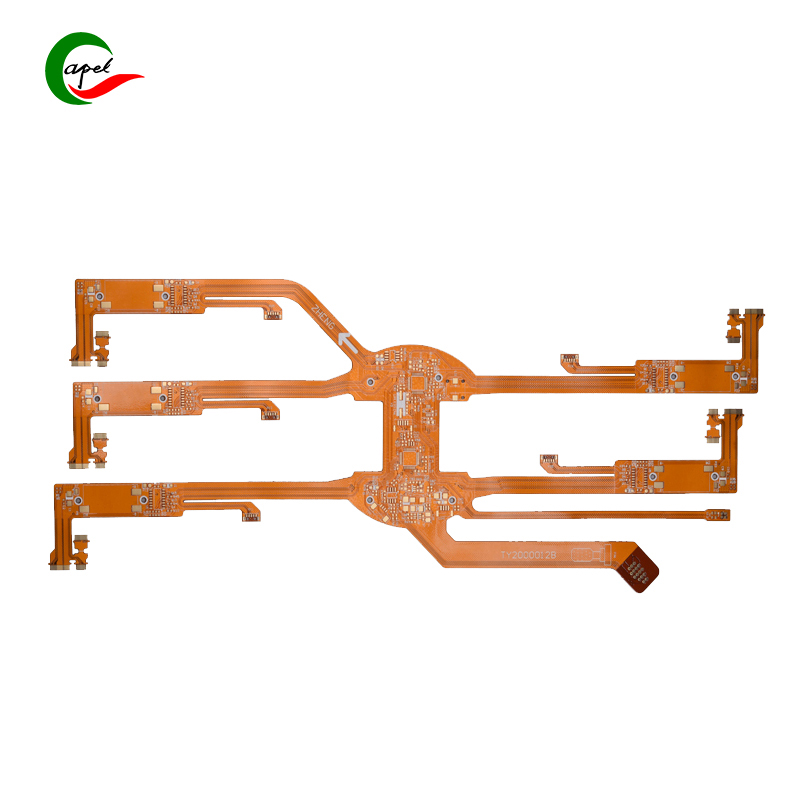

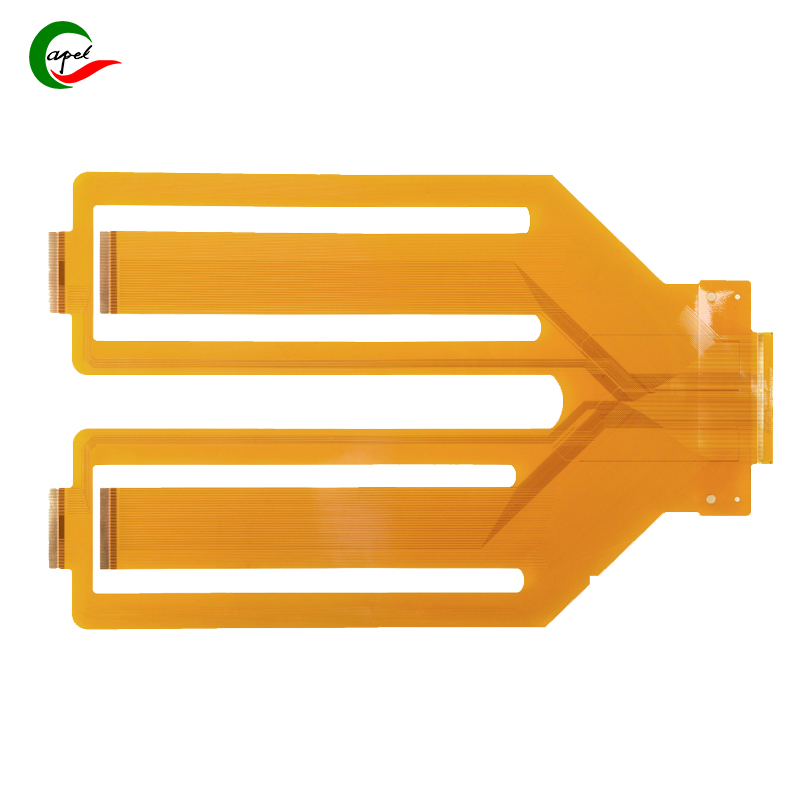

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

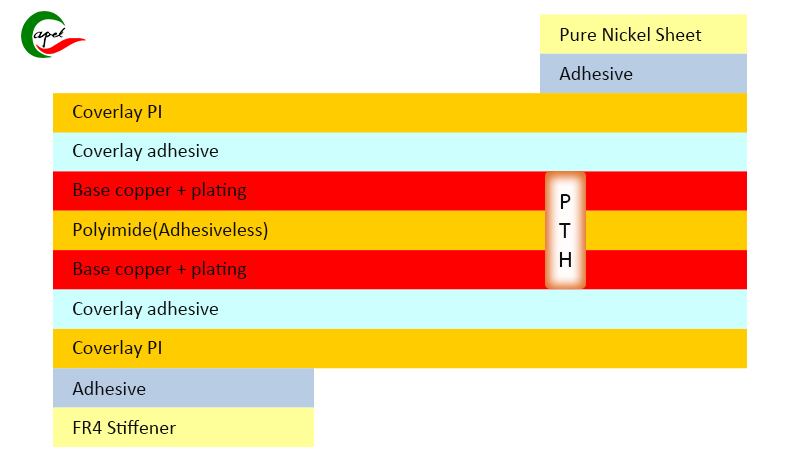

2 Layer Flexible PCB Boards Stackup

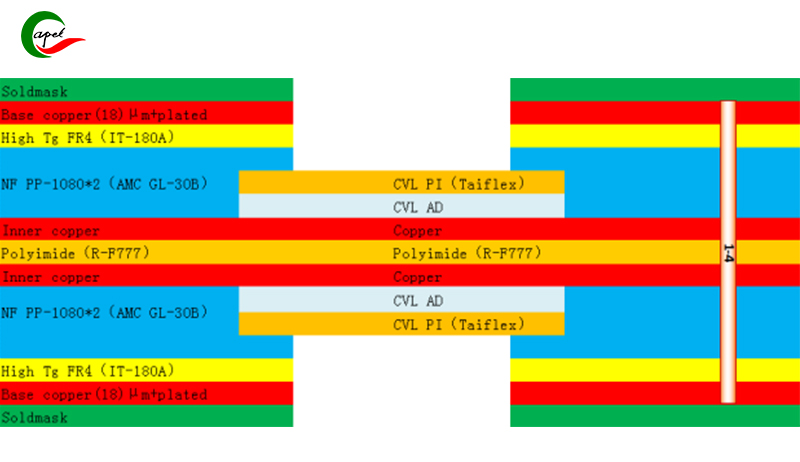

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.