smart wearable flex pcb circuit board | Smart Ring Rigid Flex PCB

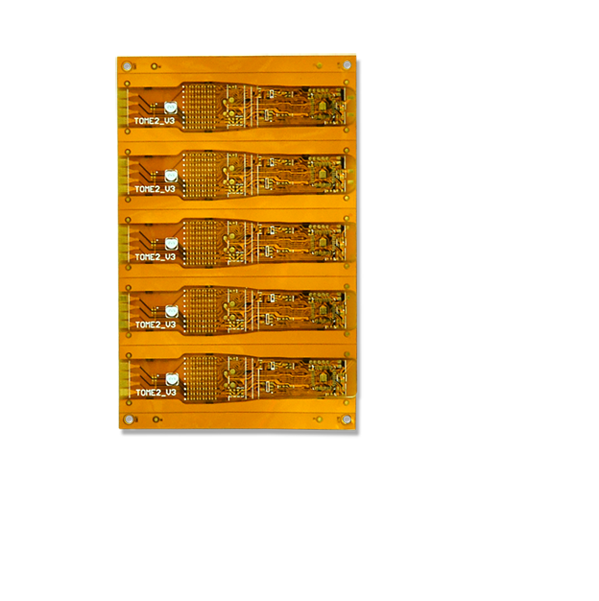

Successful cases of flexible circuit boards in smart rings:

-Capel with 15 years of professional technical experience-

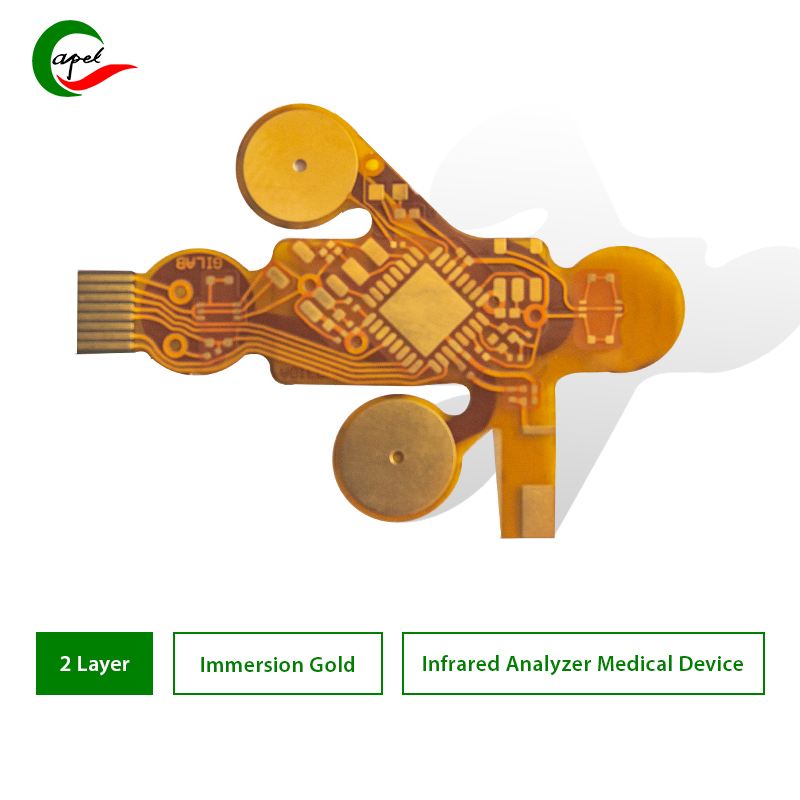

Developments in the fields of flexible electronics and wearable devices have led to many compelling innovations. Among them, the application of smart wearable PCB boards has attracted much attention. This technology not only makes smart rings more flexible and comfortable but also provides products with more design freedom. Below we will introduce a smart ring product based on flexible circuit boards and reveal its success cases and impact.

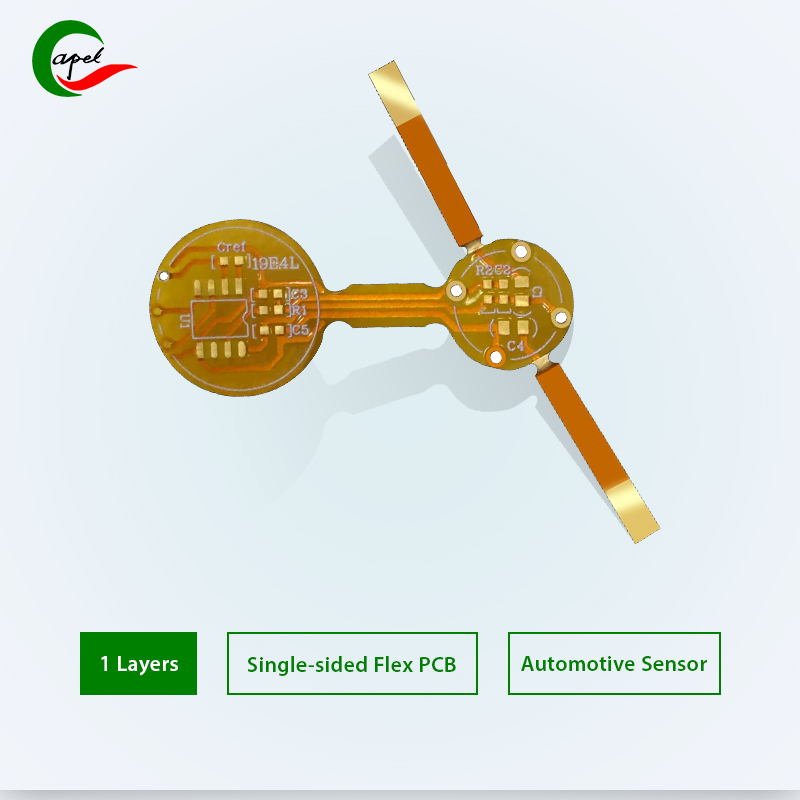

product description

The smart ring FPC board technology can realize wireless connection with smartphones or other devices and has functions such as heart rate monitoring, exercise tracking, and notification reminders. Its appearance design is fashionable, thin, comfortable, and suitable for daily wear. The flexible circuit board used not only ensures the flexibility and comfort of the product but also provides good electrical performance and reliability.

Technological Innovation and Key Advantages

Strong flexibility and plasticity: Based on the design of flexible circuit boards, the ring can be bent freely without affecting the normal operation of electronic components, greatly improving the comfort and wearing experience of the product.

High space utilization: The flexible circuit board can be bent and folded according to the curved surface design of the ring, which can effectively utilize the internal space of the ring and increase the layout flexibility of functional components.

Lightweight design: Compared with traditional rigid circuit boards, the design of flexible circuit boards can not only reduce the weight of the product but also adapt to users' needs for lightness and comfort.

Stable performance: The materials and manufacturing processes of flexible circuit boards can effectively reduce the performance degradation of smart ring printed circuit boards under deformation conditions such as bending, stretching, or extrusion, ensuring the stability and reliability of the product.

success case

Capel has rich experience and deep accumulation in the application of flexible circuit board technology. They have achieved breakthroughs in many technical problems and successfully applied flexible circuit boards into smart ring products, becoming the leader in the industry.

technological breakthrough

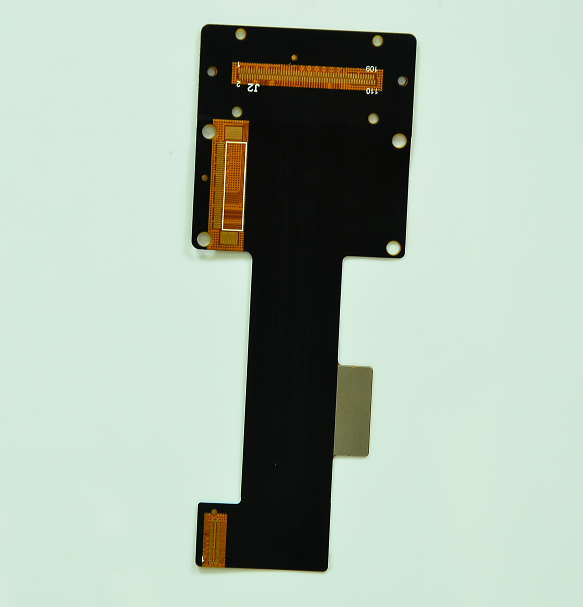

Capel has overcome several technical challenges in the research and development of smart wearable ring PCB, including material selection, process manufacturing, and integrated hardware and software design. They developed highly flexible substrates suitable for curved surface applications, effectively improving the bending and plasticity of circuit boards. At the same time, Capel has also improved its production process to achieve high-precision manufacturing of finished products, ensuring the stability and reliability of product functional components. In addition, in the integrated design of software and hardware, they carefully designed the connection between the chip on the board (SoC) and the flexible circuit board, so that the overall performance of the product can be optimally exerted.

market response

This smart ring product has been warmly welcomed by the market with its advanced smart ring PCB assembly technology and rich functional features. Users commented positively on the comfort and functionality of the product, and sales and word-of-mouth success were achieved. At the same time, this product has also been recognized and praised by many professional evaluation institutions, becoming the leader among similar products. Thanks to the successful application of flexible circuit board technology, our customers have achieved significant competitive advantages in the wearable device market.

Impact on the industry and prospects

Through this case, we can see the profound impact of the application of flexible circuit board technology in the field of smart rings. First of all, technological innovation promotes the progress of product functions and appearance design, improving user experience and product competitiveness. Secondly, the successful application of flexible circuit boards has set a technological pioneer model for the entire wearable device industry, improving the technical level and product quality of the entire industry chain. At the same time, with the continuous improvement of flexible circuit board manufacturing processes and cost reduction, flexible electronic technology will bring broader space for the innovation and development of mass consumer electronics products.

Looking to the future, with the continuous advancement of smart ring rigid-flex PCB technology and wearable device technology, we believe that more innovative and functional smart ring products will emerge and provide users with a better user experience. At the same time, the successful cases of flexible circuit board technology will also inspire more technology companies and innovation teams to jointly explore the infinite possibilities in the field of wearable devices.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

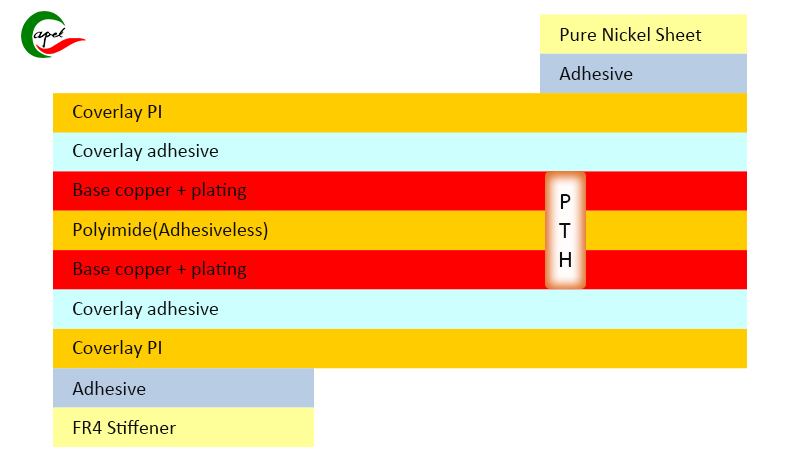

2 Layer Flexible PCB Boards Stackup

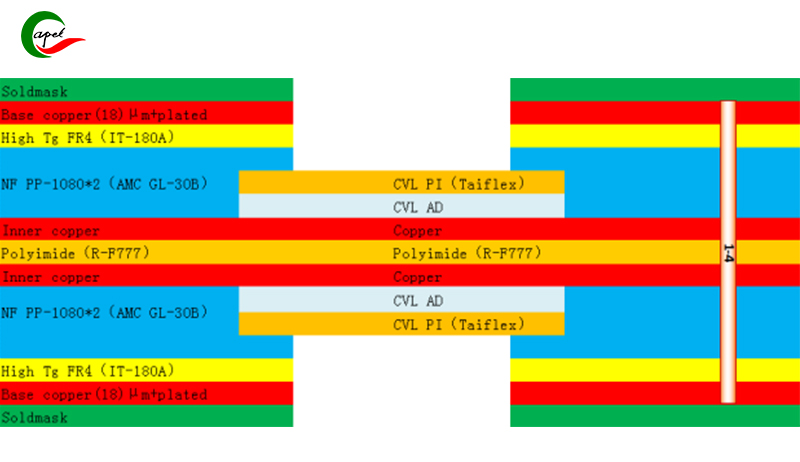

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

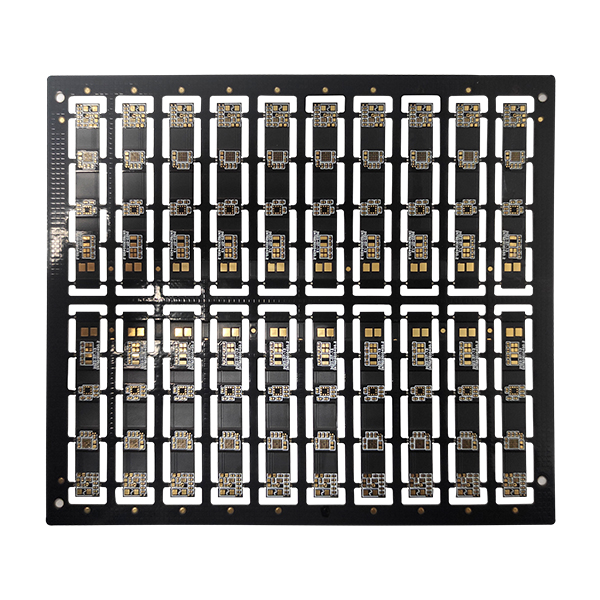

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.