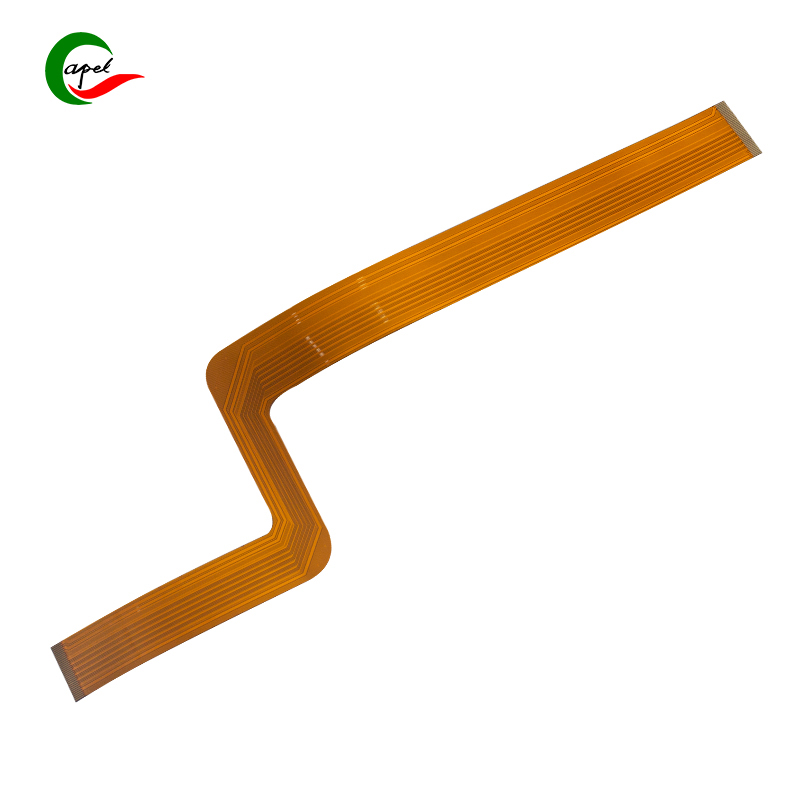

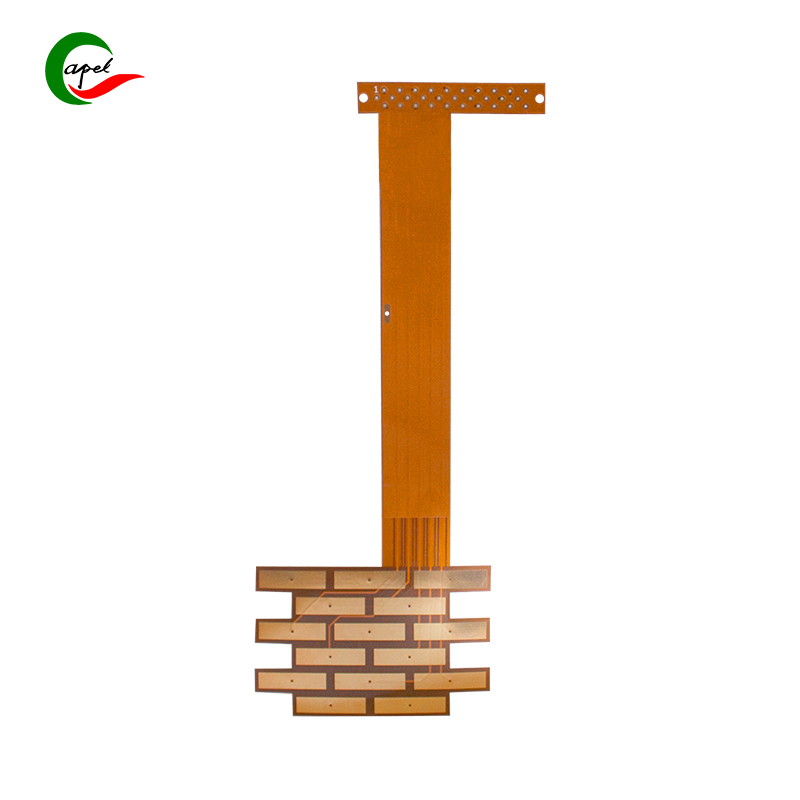

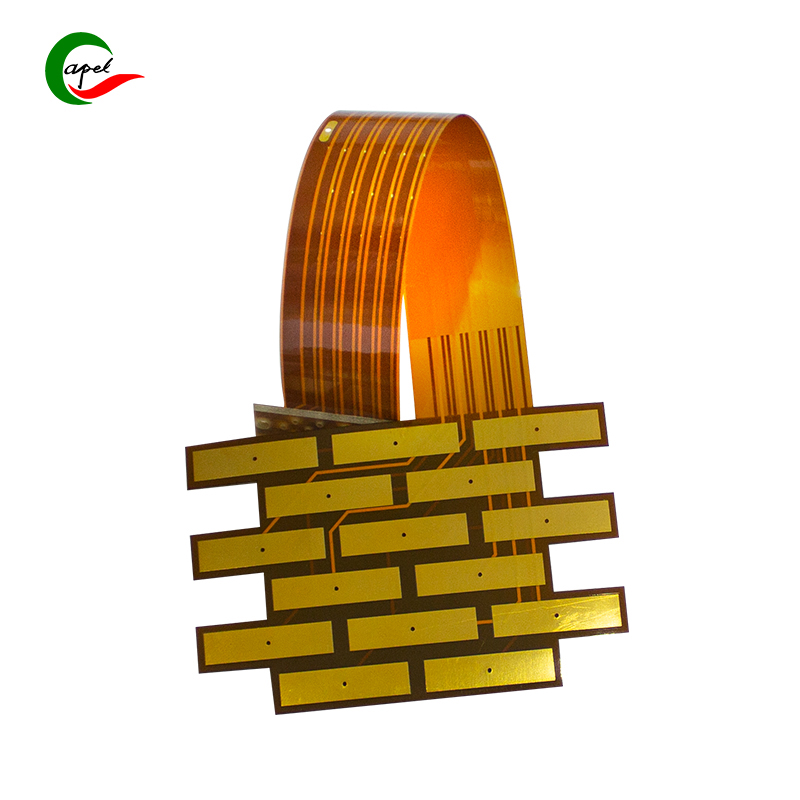

Single-Layer Flexible PCBs Single-Sided Flexible Printed Circuit Boards for Consumer Electronic

Specification

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi- layer FPC / Aluminum PCBs Rigid-Flex PCBs |

Layers Number | 1-16 layers FPC 2-16 layers Rigid-FlexPCB HDI Printed Circuit Boards |

| Max Manufacture Size | Single layer FPC 4000mm Doulbe layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

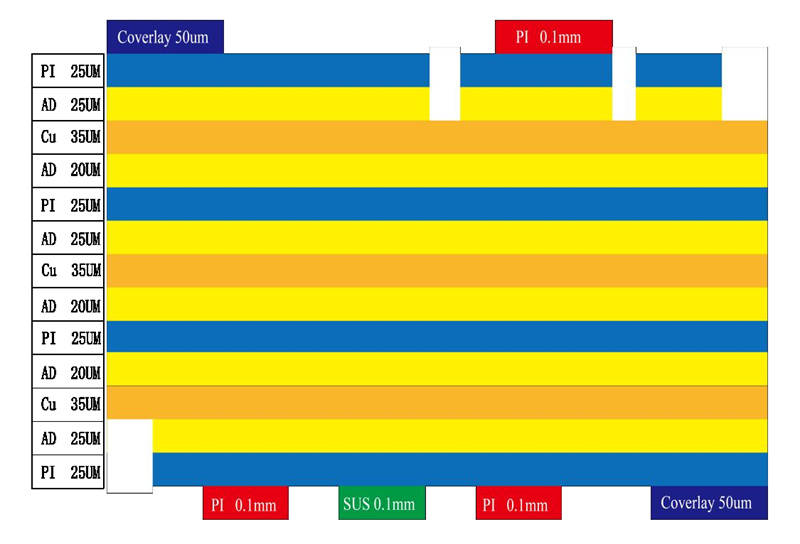

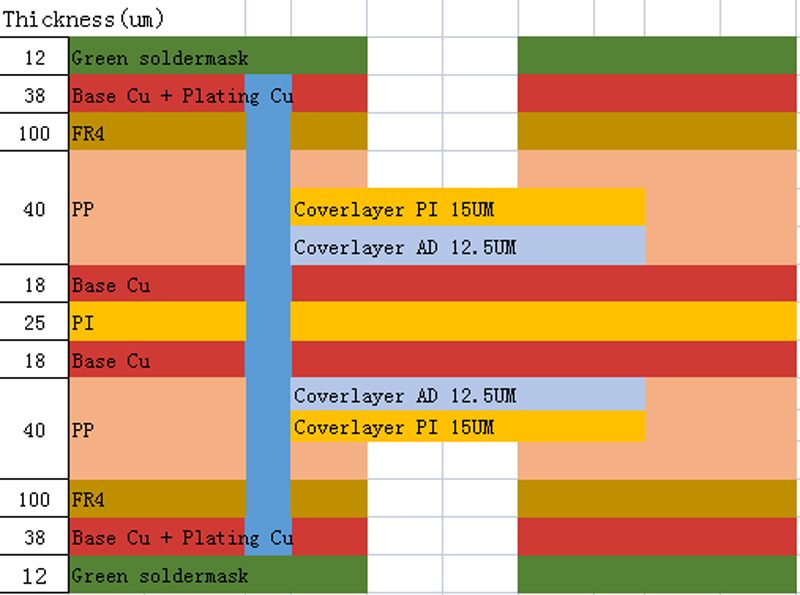

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plat ing/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

We do single-layer flexible PCBs with 15 years' experience with our professionalism

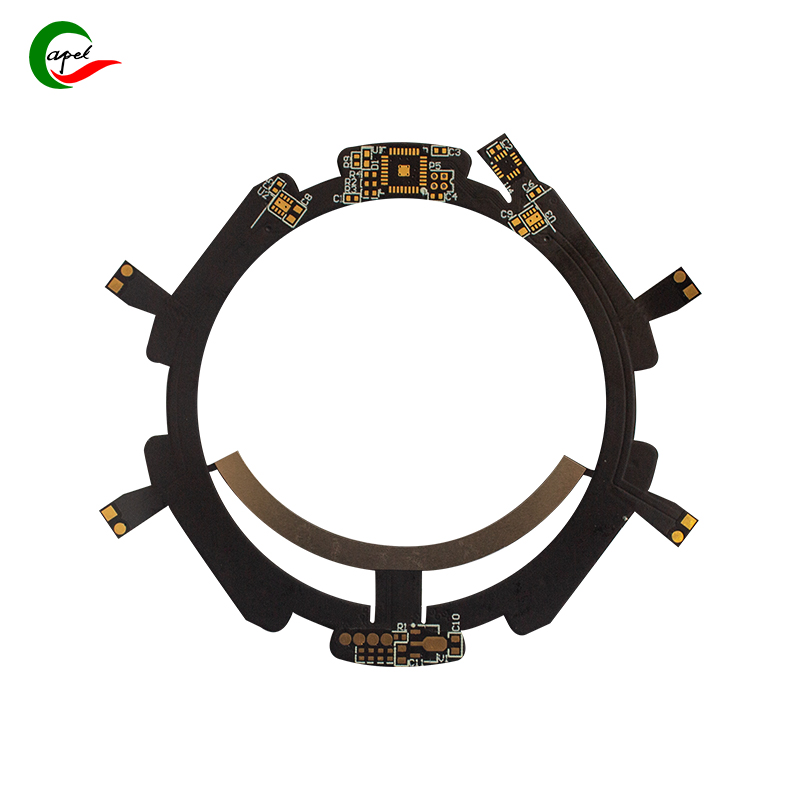

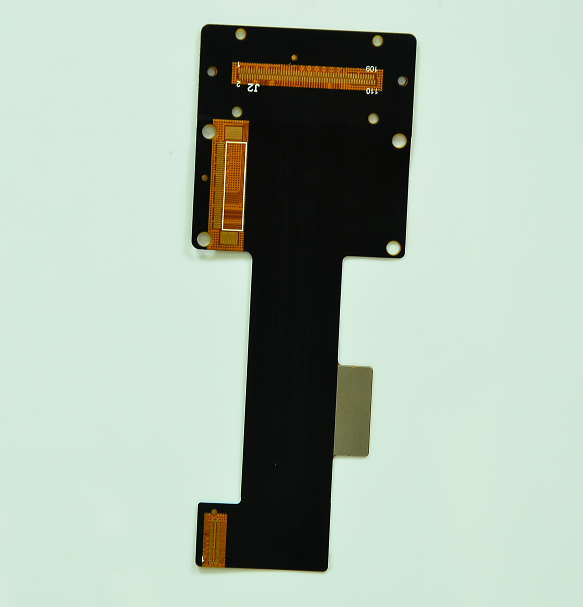

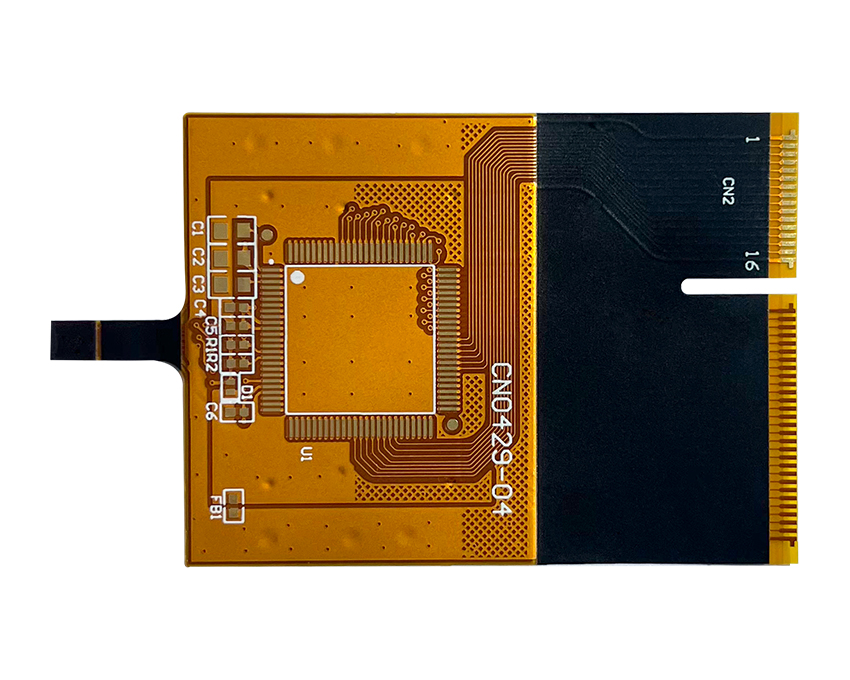

3 layer Flex PCBs

4 layer Rigid-Flex PCBs

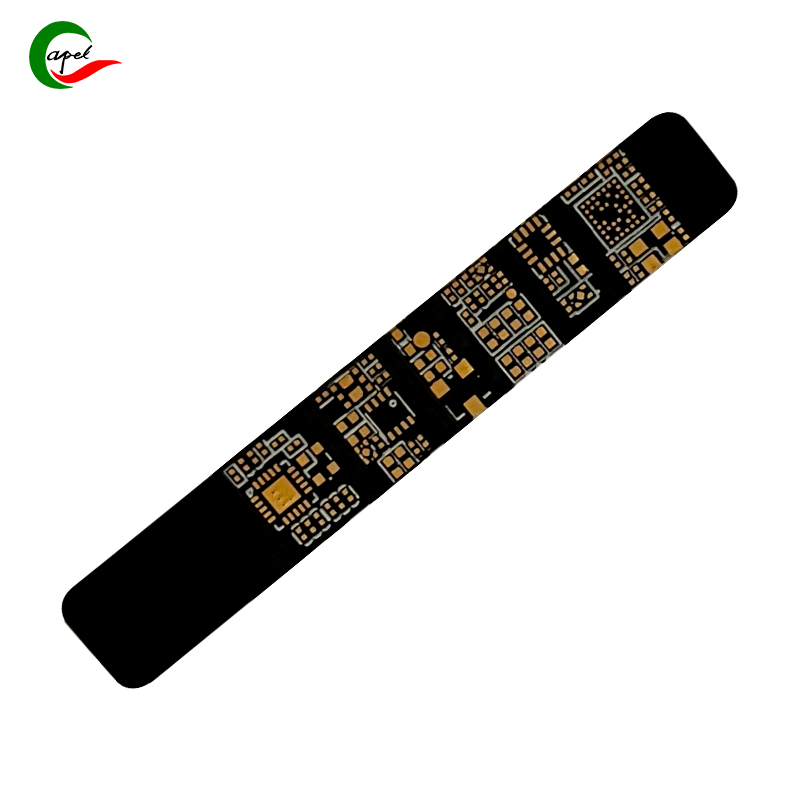

8 layer HDI Printed Circuit Boards

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Our single-layer flexible PCBs Service

. Provide technical support Pre-sales and after-sales;

. Custom up to 40 layers, 1-2days Quick turn reliable prototyping, mass production,Component procurement, SMT Assembly;

. Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc..

. Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

How single-side flexible printed circuit boards applicated in watches

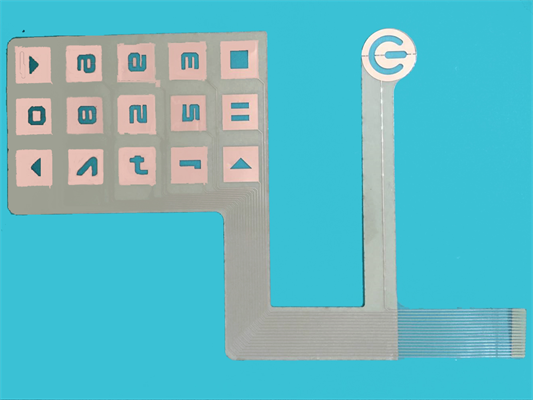

Single-sided flexible printed circuit boards (PCBs) are commonly used in a variety of watch applications, including:

1. Component Mounting: A single-sided flex PCB provides a platform for the mounting and interconnection of electronic components used in watches such as microcontrollers, displays, batteries, and other supporting components. These PCBs have copper traces for routing electrical signals and pads for soldering components.

2. Compact design: Watches are usually small in size, and a single-sided flex PCB allows for a compact and efficient design.

The flexibility of the PCB allows it to be bent, folded, or shaped to fit within the limited space of a watch while still providing a reliable electrical connection.

3. Space optimization: Single-sided flexible PCB can effectively use the watch space. A single layer allows for a thinner profile, maximizing interior space and allowing more components or functions to be contained within the watch's limited dimensions.

4. Flexibility and Durability: The flexibility of these PCBs allows them to withstand the mechanical stresses encountered in normal use or when assembling a watch, such as bending and twisting. This flexibility makes them more resistant to damage and malfunction, ensuring that the watch will remain functional even under constant motion.

5. Reliable connection: Single-sided flex PCB is designed with copper traces, which can provide reliable electrical connection between components. These connections are critical to the watch's smooth operation and accurate timekeeping. The single layer construction simplifies the assembly process and reduces the possibility of connection problems.

6. Cost-effective production: Single-sided flex PCBs are generally less complex and require fewer materials and manufacturing steps than multilayer PCBs. This results in a more cost-effective production process, making it attractive to watchmakers looking for an efficient solution.

7. Customization and personalization: Single-sided flexible PCB can be customized to meet the specific design requirements of the watch, such as a unique shape or the integration of specific functions. Watch manufacturers can modify the size, shape and layout of the PCB to accommodate different design elements or to incorporate specific functions.

single-sided flexible board in watches FAQ

1. What is a single-sided soft board?

- A single-sided flex PCB is a printed circuit board that has copper traces and pads on one side only.

Made from flexible materials such as polyimide or polyester, they can be bent or shaped to meet the specific design requirements of the watch.

2. What is the application of single-sided flexible board in watches?

- Single-sided flexible PCBs are used in watches for component mounting, interconnecting electronic parts, and providing a platform for electrical connections. They are responsible for routing signals between components such as microcontrollers, displays, batteries, and other watch functions.

3. What are the advantages of single-sided flexible boards in watches?

- Single-sided flex PCB offers several advantages in watch applications. They allow compact design, optimal use of space and flexibility to withstand mechanical stress. They also provide a reliable electrical connection and can be customized to meet specific design requirements.

4. Can a single-sided flex PCB be bent or shaped to fit within the limited space of a watch?

- Yes, single-sided flex PCBs are specifically designed to be flexible and can be bent or shaped to fit within the constraints of the watch design. Their flexibility allows them to adapt to the available space without compromising electrical connections.

5. Are single-sided flex PCBs more durable than traditional rigid PCBs?

- Yes, single-sided flex PCBs are generally more durable than rigid PCBs due to their flexibility. They can withstand the bending, twisting and other mechanical stress encountered during watch use or assembly, making them more resistant to damage and failure.

6. Is a single-sided flex PCB cost-effective for watch manufacturing?

- Yes, single-sided flex PCBs are generally more cost-effective for watch manufacturing than complex multi-layer PCBs. Their simpler design requires fewer materials and manufacturing steps, reducing production costs.

7. Can the single-sided flex PCB be customized for a specific watch design?

- Yes, the single-sided flex PCB can be customized to meet the specific design requirements of the watch. They can be modified in size, shape and layout to accommodate different design elements or integrate specific functions according to the needs of the watch manufacturer.

8. Is single-sided soft board widely used in the watch industry?

- Yes, single-sided flex PCBs are commonly used in the watch industry for their various advantages and suitability for small and compact designs. Their use is prevalent in both traditional analog watches and modern smartwatches.