Rigid Flex Circuits Online Pcb Manufacturer Hdi Pcb Prototype

How Capel's Rigid Flex Circuits Provide Reliability Solutions for Car Combination Switch Lever Automakers

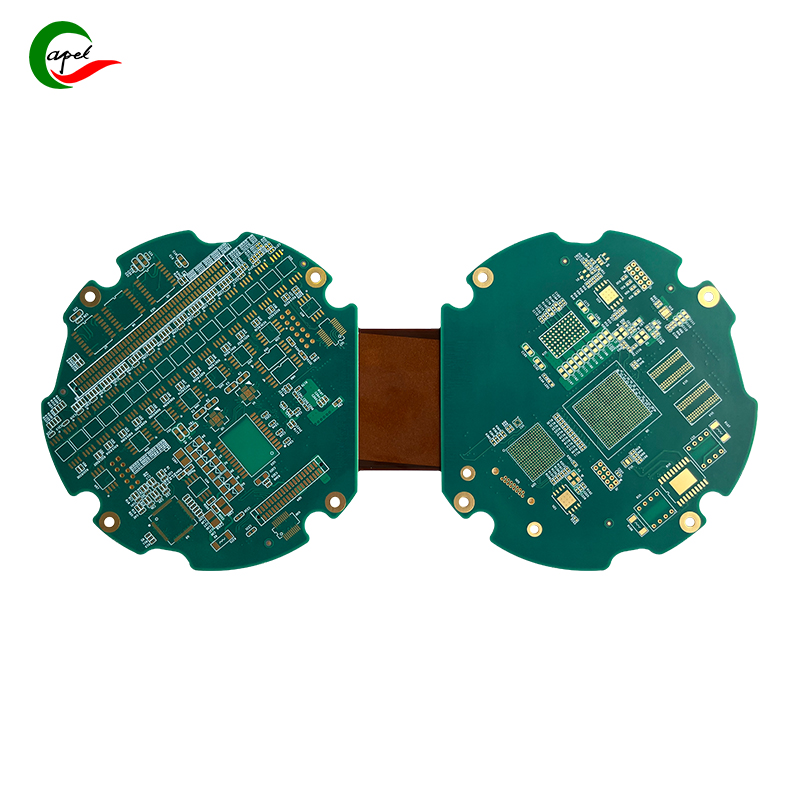

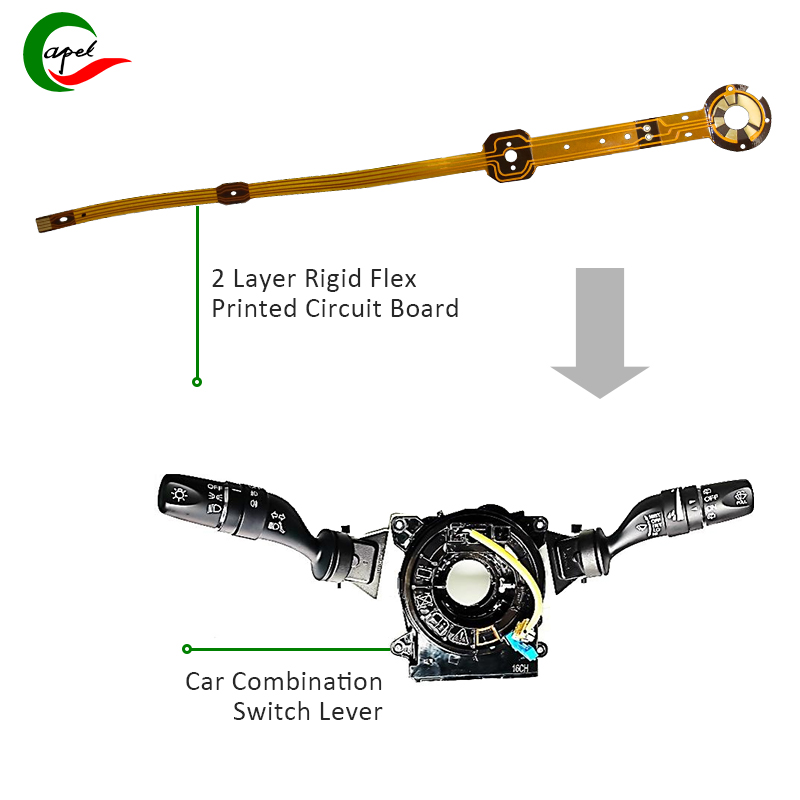

2 Layer Rigid Flex Printed Circuit Board applicated in GAC Motor Car Combination Switch Lever

-Capel with 15 years of professional technical experience-

Capel 2-Layer Rigid-Flex PCB: A Reliable Choice for GAC Automotive Combination Switch Lever

introduce:

In today's auto industry, advanced technology and high-performance components are the key, and GAC Motor is a brand that continues to soar. When it comes to a combination switch lever in a car, it is an integral part that seamlessly controls various functions, so the reliability and performance of the electronics involved becomes critical. This is where Capel's 2-layer rigid-flex printed circuit board (PCB) comes into play, with its high adhesion and reliability, making it the ideal solution for GAC Passenger Vehicle combination switch levers.

product description:

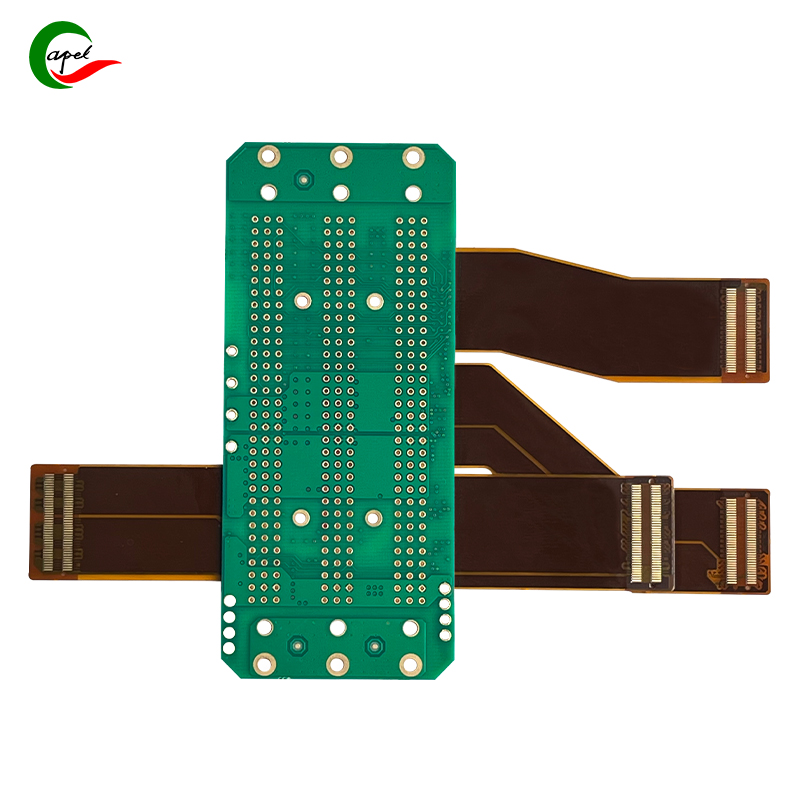

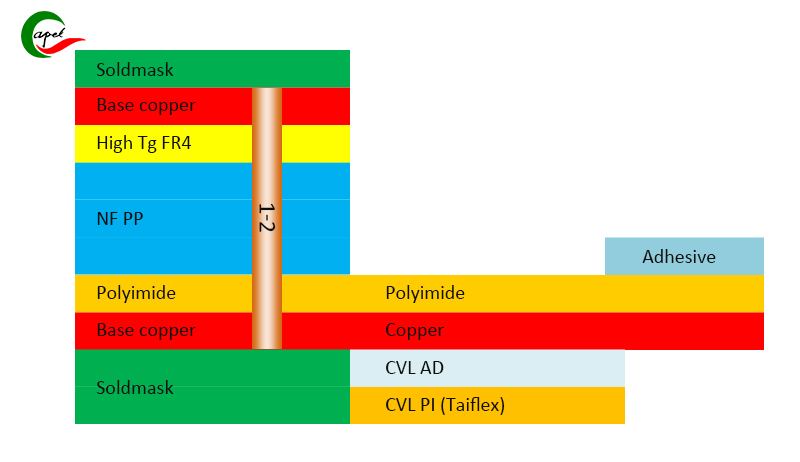

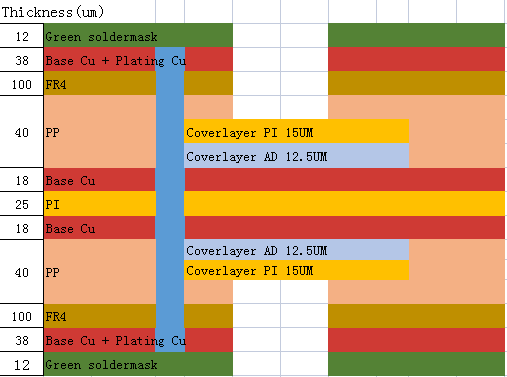

Capel's 2-layer rigid-flex PCBs are specifically designed to meet the stringent requirements of automotive applications. The PCB is a rigid-flex product type and a 2-layer configuration designed to provide optimum performance in harsh environments. Its line width and line spacing are 0.15MM/0.1MM, ensuring enhanced data transmission capability. The plate thickness FPC is 0.15MM and T is 1.6MM, which achieves a perfect balance between structural integrity and flexibility.

Main features:

1. High adhesion: Capel's 2-layer rigid-flex PCB has excellent adhesion, ensuring the longevity and reliability of the combined switch lever electronics. This feature prevents the risk of critical connections becoming loose or detached, providing uninterrupted functionality throughout the life of the car.

2. High reliability: Capel PCB adopts strict manufacturing process in the manufacturing process to ensure high reliability under extreme conditions. Each component undergoes rigorous testing including AOI (Automated Optical Inspection), four-wire testing, continuity checks and copper strip evaluation. This extensive testing ensures that only the highest quality PCBs are integrated into GAC Motor vehicles.

Specifications:

- Copper thickness: 1OZ

- Film thickness: 50UM

- Surface treatment: ENIG 2-3uin

- Tolerance requirement: 0.1MM

- Material: Shengyi TG170 copper clad laminate

application:

Capel's 2-layer rigid-flex PCB is designed for GAC Motor's combination switch lever, a key component responsible for controlling various functions of the car. The integration of Capel PCB ensures seamless operation, providing GAC Trumpchi owners with a reliable and user-friendly experience.

in conclusion:

Reliability and durability are critical when selecting the correct components for automotive applications. Capel's 2-layer rigid-flex PCB with high adhesion and reliability is tailored to meet the stringent requirements of GAC Passenger Vehicle combination switch levers. Capel has a strong reputation in the automotive electronics industry, delivering the highest quality products to ensure a seamless driving experience for GAC Trumpchi owners.

Investing in Capel's 2-layer rigid-flex PCB ensures that GAC Motor remains at the forefront of technological advancements, delivering reliable, efficient performance. As the automotive industry continues to evolve, Capel remains committed to providing cutting-edge solutions that redefine the boundaries of innovation in the PCB market. Choose Capel for uncompromising quality and unwavering reliability with every drive.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

2 Layer Rigid Flex Printed Circuit Board

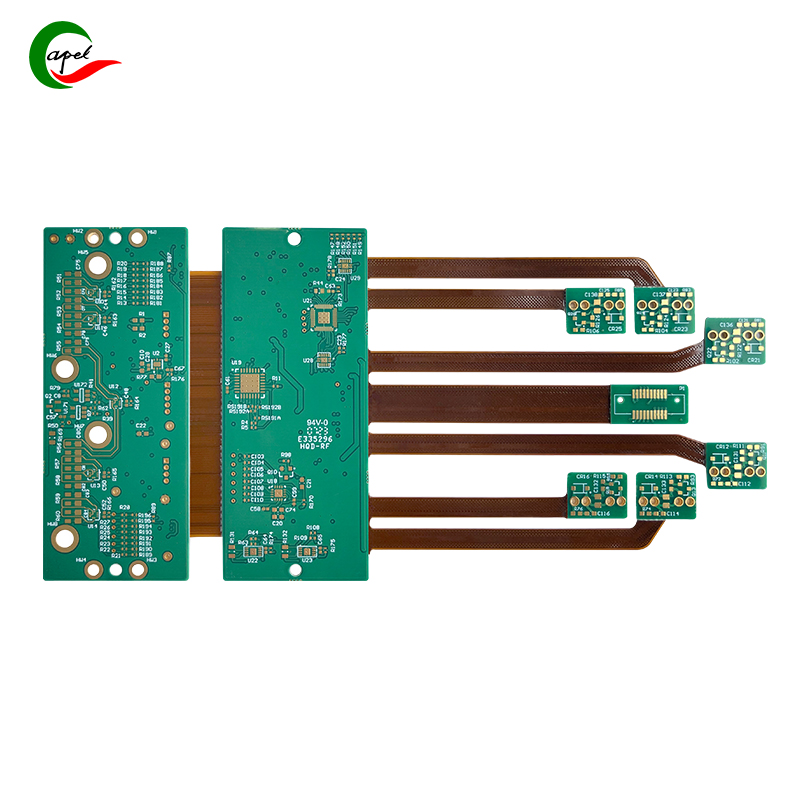

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

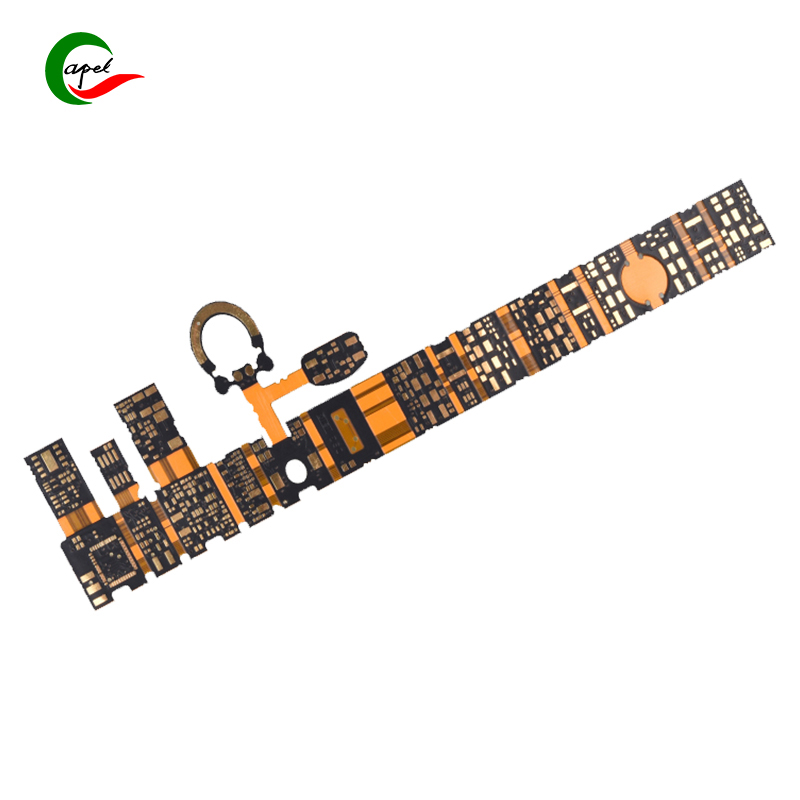

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.