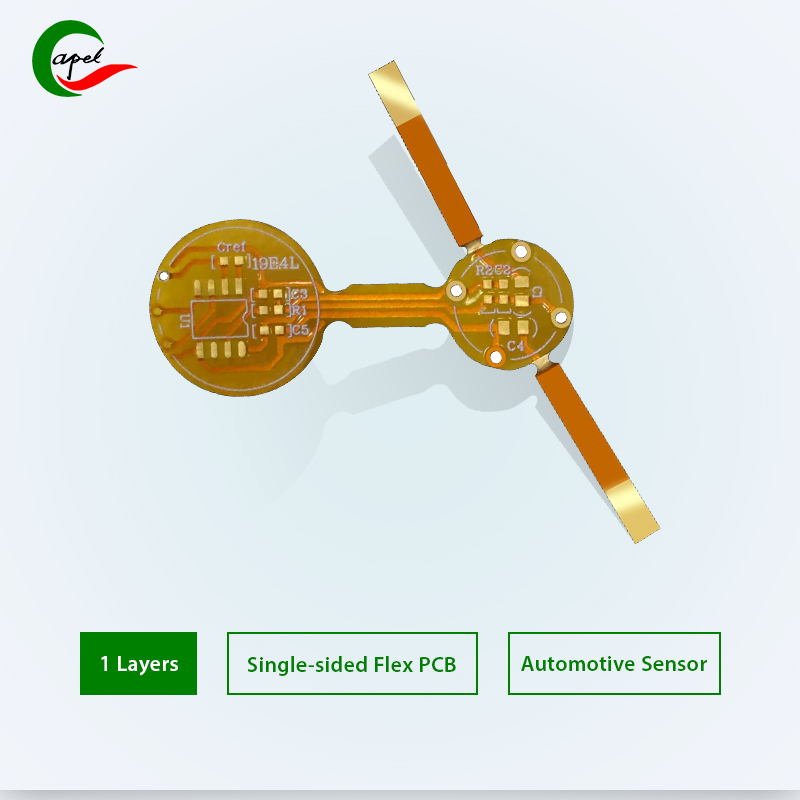

Rapid Flex Pcb Manufacturing Maker Online Single Layer Pcb Price

How Capel's Rapid Flex Pcb Manufacturing Maker Online Single Layer Pcb 18um Provide Reliability Solutions for Cosmetic instrument medical equipment manufacturer

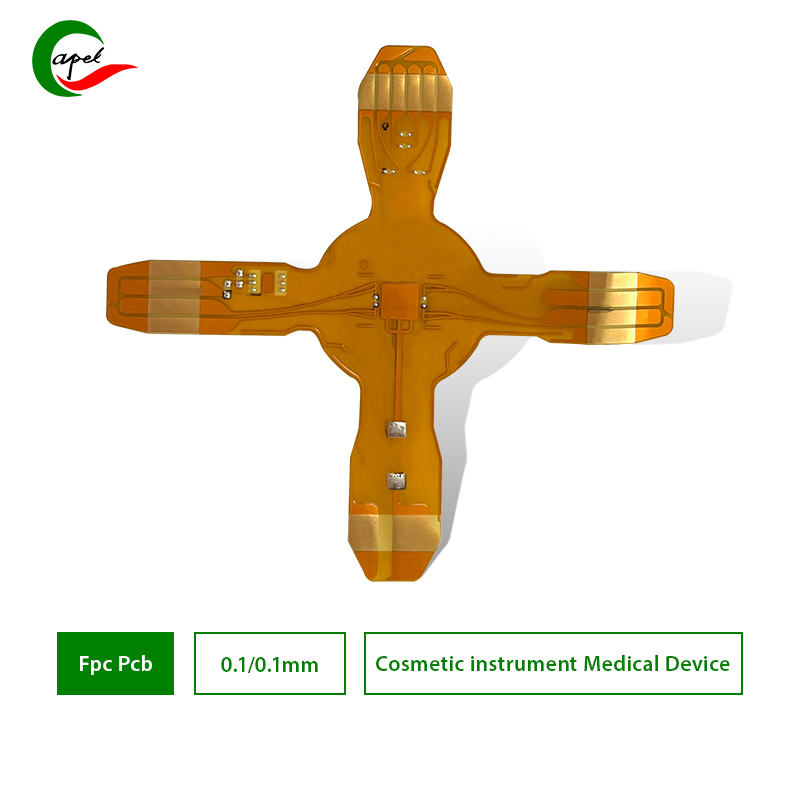

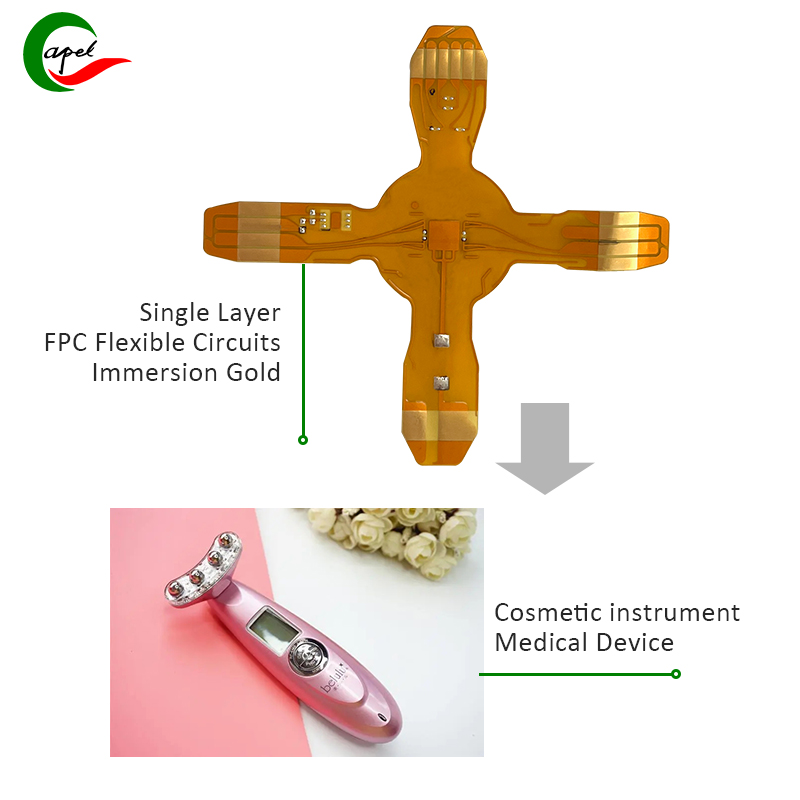

Single Layer Pfc Flexible Circuits applicated in Cosmetic instrument Medical Device

-Capel with 15 years of professional technical experience-

Pfc Flexible Circuits: The Gold Standard for Medical and Aesthetic Applications

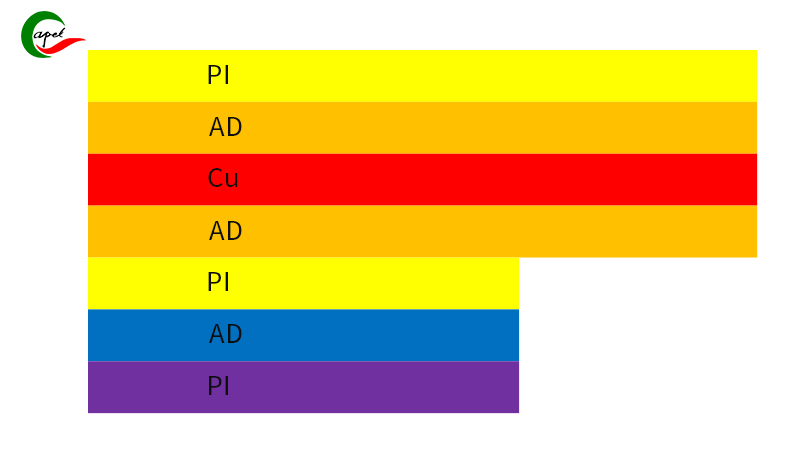

In the field of technology and innovation, there is a growing demand for flexible and reliable electronic components. Manufacturers are constantly exploring new materials and designs to meet these demands and improve product performance. One advancement in electronic components is the use of Pfc flexible circuits, which are designed for medical device and beauty instrument applications.

Pfc flexible circuits, also known as single-layer PCBs (printed circuit boards), are revolutionizing the way electronic components are integrated into various devices. These circuits offer a unique combination of flexibility, durability and compactness not possible with traditional rigid PCBs.

So, how can Pfc flexible circuits be used in beauty instrument and medical device applications? Let's take a deeper look at their features and benefits.

Product Type: Pfc Flexible Circuit

Pfc flexible circuits are designed for applications requiring flexibility and compactness. With their single-layer design, these circuits offer maximum flexibility and can be easily folded, bent and shaped to fit any desired form factor.

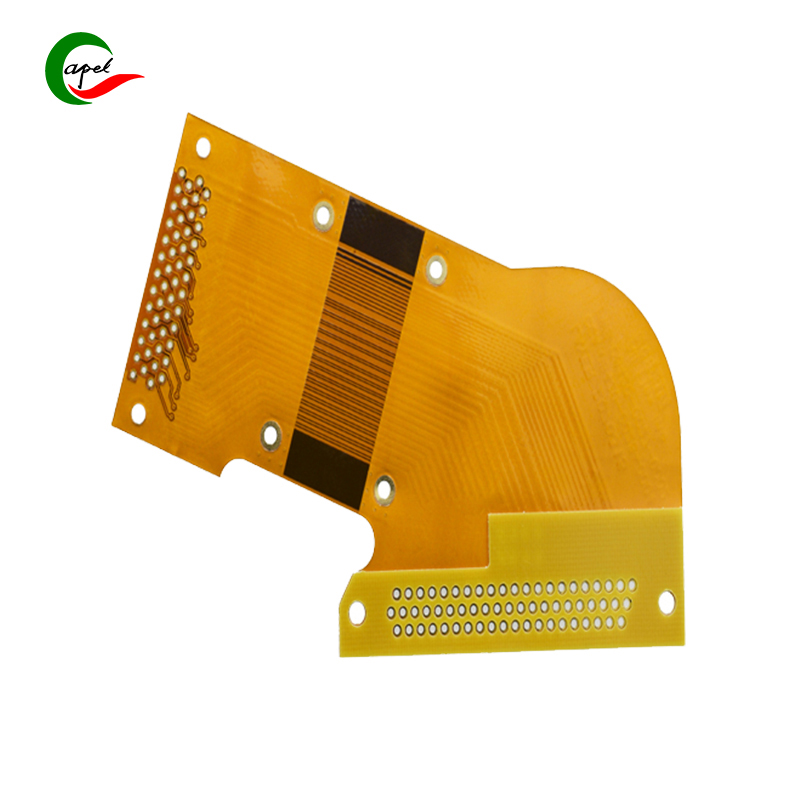

Number of layers: 1 layer / single layer PCB

As a single-layer PCB, Pfc flex circuits offer a relatively simple and stylish design without complex multi-layer configurations. This simplicity contributes to their flexibility and makes them ideal for medical devices and beauty instruments.

Line width, line spacing: 0.1/0.1mm

Pfc flex circuits have ultra-fine line width and pitch, ensuring precise current flow and minimizing any signal interference. This feature is especially important for medical devices that require accurate and reliable data transmission for optimal performance.

Plate thickness: 0.1mm

The Pfc flexible circuit board is only 0.1 mm thick, which significantly reduces the overall size and weight of the integrated device. Medical equipment and beauty instruments are usually used in sensitive and delicate scenes, greatly benefiting from the compactness and light-weight characteristics of Pfc flexible circuits.

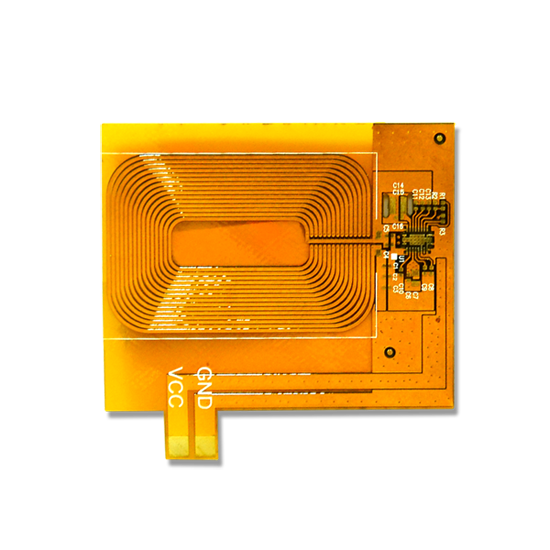

Copper thickness: 18um

The copper layer in Pfc flex circuits is critical to conduct electricity. These circuits have a copper thickness of 18um to provide a robust and reliable connection between various electronic components, ensuring seamless functionality.

Minimum aperture: 0.3mm

Minimum aperture in Pfc flex circuits is the smallest hole or opening within the circuit. With apertures as small as 0.3 mm, these circuits accommodate small electronic components, including microchips and sensors, required for advanced medical and cosmetic applications.

Flame retardant: 94V0

Safety is of paramount importance for medical and cosmetic devices. Pfc flexible circuits are manufactured using flame retardant materials ensuring that any potential fire hazard is minimized. The 94V0 rating ensures that the circuit meets stringent safety standards.

Surface treatment: immersion gold

A prominent feature of Pfc flexible circuits is the use of immersion gold as the surface treatment. Immersion gold has excellent electrical conductivity, durability and corrosion resistance. This treatment extends the life of the circuit, making it suitable for long-term use in medical devices and beauty instruments.

Resistance welding color: yellow

Pfc flexible circuits are available in a variety of resistance solder colors, allowing manufacturers to customize circuits to their exact requirements. Yellow indicates the use of high-quality materials to ensure easy identification during manufacturing and assembly.

Application: Medical Devices

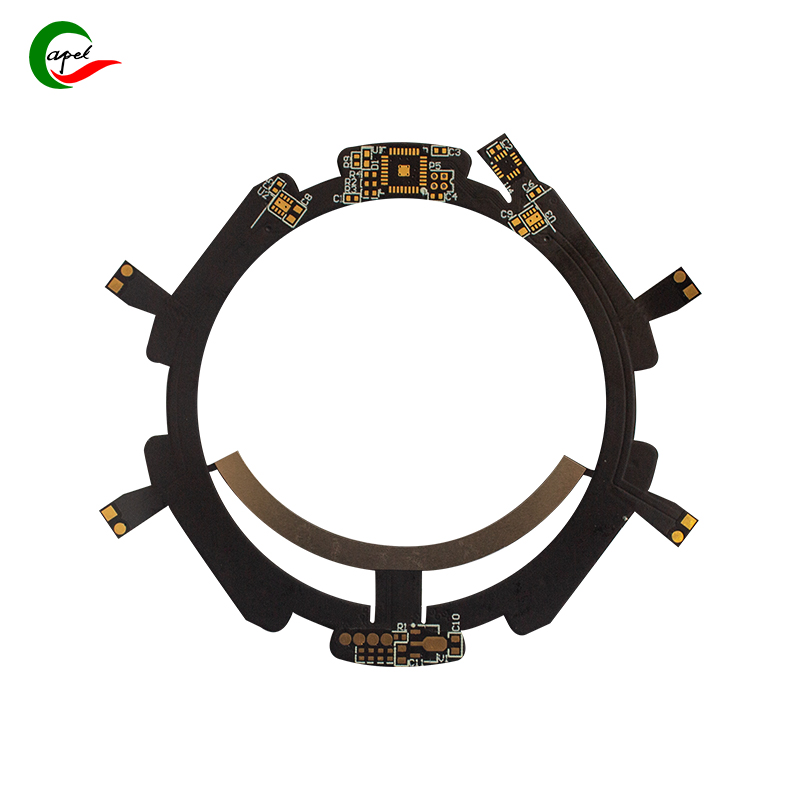

The applications of Pfc flexible circuits in the medical device industry are wide and varied. From wearable health monitors to implantable devices, these circuits play a vital role in ensuring accurate data monitoring, precise control and seamless communication in medical environments.

Application device: beauty equipment

Beauty instruments require precise control and accurate data transmission for optimal performance. Pfc flexible circuits enable the integration of advanced electronic components into beauty instruments for enhanced functionality, user-friendly operation and improved overall user experience.

In conclusion, Pfc flexible circuits have changed the face of electronic components with its immersion gold finish and unique product features. Their flexibility, compactness and reliability make them the gold standard for medical device and aesthetic instrumentation applications.

Whether used in life-saving medical devices or state-of-the-art beauty instruments, Pfc flexible circuits deliver unrivaled performance and contribute to the advancement of the healthcare and beauty industries. Able to accommodate complex electronic configurations and provide seamless data transfer, Pfc flexible circuits are truly the future of electronic component design.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

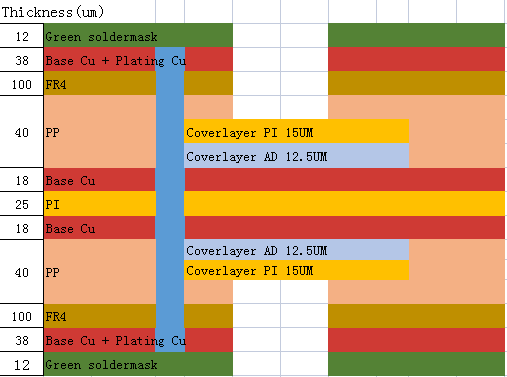

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

Single Layer Pfc Flexible Circuits

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.