Quick Turn Prototype 4 Layer Pcb Stackup Flex Pcb Manufacturer Immersion Gold

How Capel's Quick Turn Prototype 4 Layer Pcb Stackup Flex Pcb Manufacturer Immersion Gold Provides Reliability Solutions for Blood Pressure Medical Equipment Manufacturer

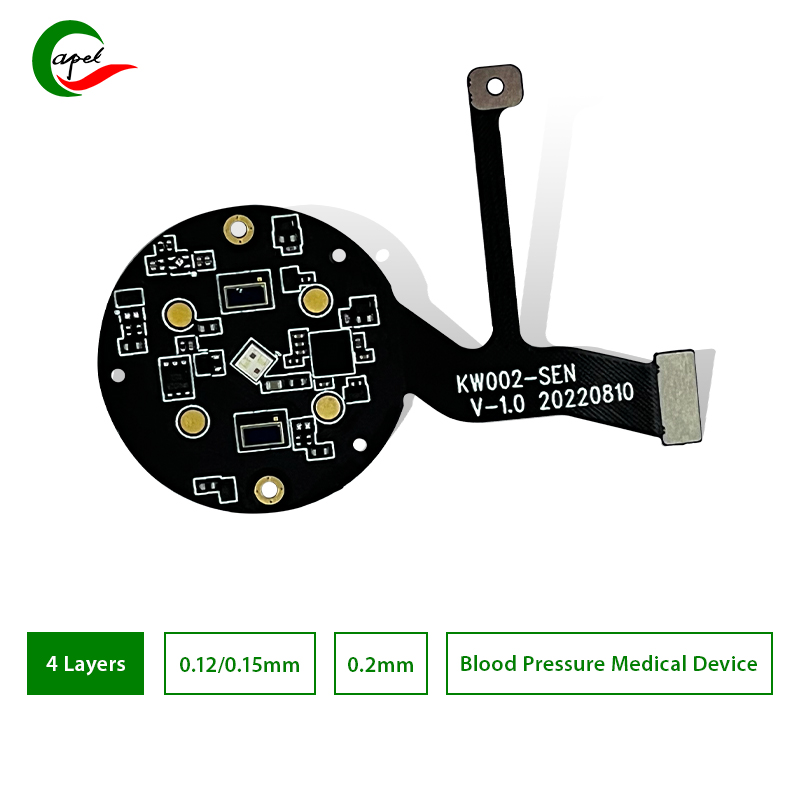

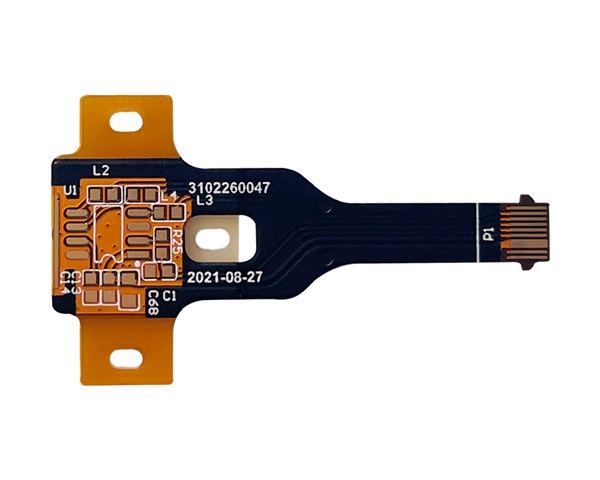

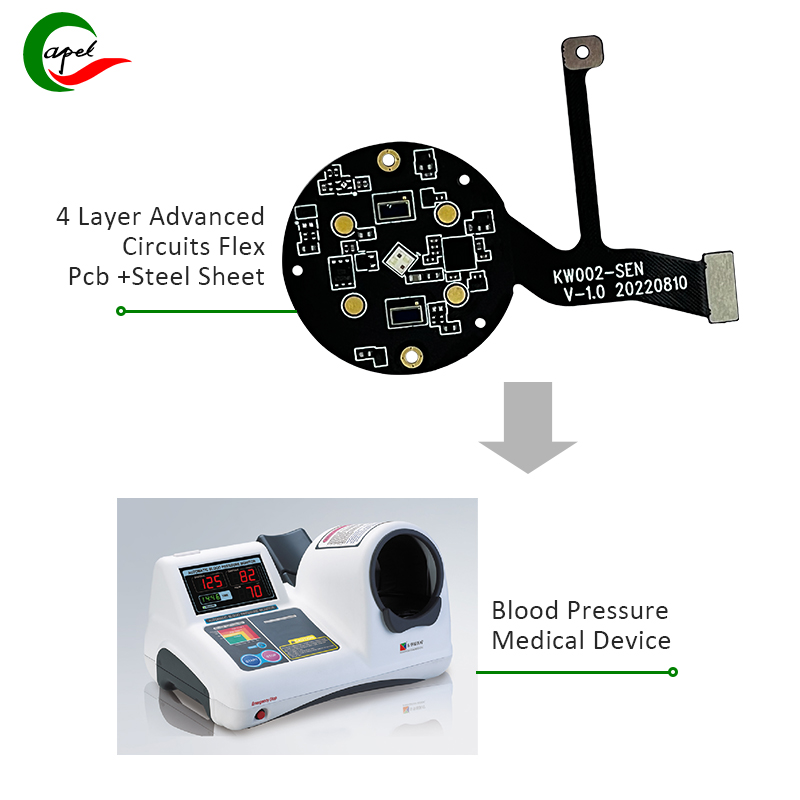

4 Layer Fpc Pcb Advanced Circuits Flex Pcb applicated in Blood Pressure Medical Device

-Capel with 15 years of professional technical experience-

How Capel's 4-Layer Fpc PCB Is Revolutionizing Blood Pressure Medical Devices

In the rapidly evolving world of medical technology, there is a growing need for innovative solutions that improve patient care. Among various medical devices, blood pressure monitors play a vital role in diagnosing and monitoring high blood pressure, which affects millions of people around the world. To meet the needs of medical professionals and patients, Capel has developed an advanced circuit flex PCB with unique features ideal for blood pressure monitoring equipment.

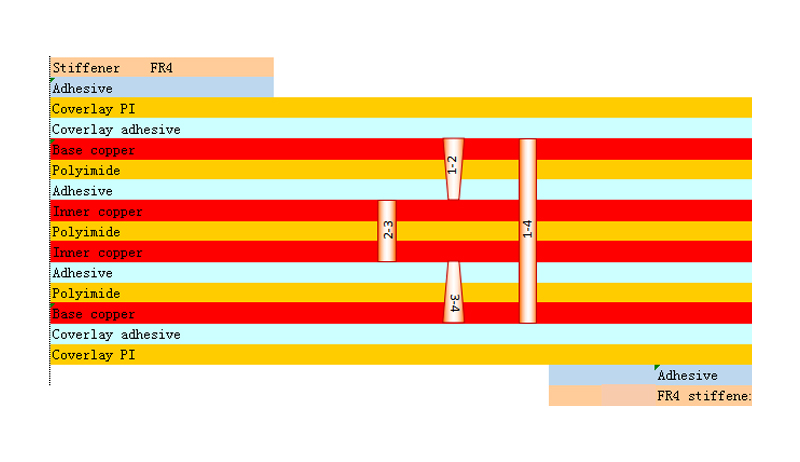

Capel's 4-layer Fpc PCB is a cutting-edge innovation that combines advanced technology with premium materials to deliver superior performance and reliability. This flexible printed circuit board has a multilayer structure that adds a new dimension to the functionality of medical devices. With its advanced circuitry, it can be seamlessly integrated in medical equipment to provide accurate, real-time blood pressure measurement.

One of the key advantages of Capel's 4-layer Fpc PCB is its advanced multi-layer design. Featuring four layers, this flexible PCB can handle complex circuit layouts, ensuring optimum performance without sacrificing space or efficiency. This makes it ideal for compact portable blood pressure monitoring devices, allowing designers to incorporate more functionality while maintaining a sleek and user-friendly design.

Capel's 4-layer Fpc Pcb has an impressively small 0.12/0.15mm line width and space setting. This precision ensures excellent signal integrity, minimizes noise interference and maximizes the accuracy of blood pressure readings. With these thin wire sizes, medical professionals can rely on the device for precise data analysis, resulting in more accurate diagnoses and personalized treatment plans.

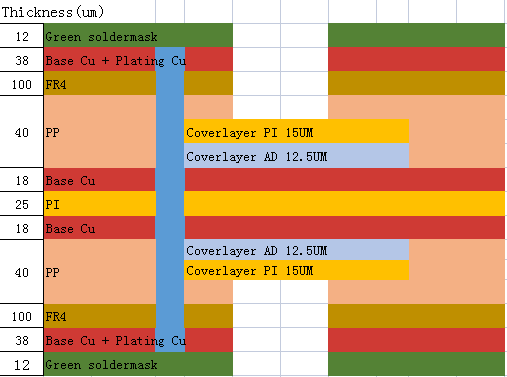

Board thickness is another key feature that differentiates Capel's 4-layer Fpc PCBs from the competition. At just 0.2 mm thick, this flexible PCB offers unrivaled flexibility and can be easily integrated into blood pressure monitoring devices. The reduced thickness also contributes to the overall compactness of the device, making it more portable for patients to use in a variety of settings.

Capel understands the importance of durability and reliability for medical devices. That's why their 4-layer Fpc PCB has a copper thickness of 35um, ensuring excellent electrical conductivity and long-lasting performance. This high-quality copper layer enables efficient transmission of signals and power, enabling accurate blood pressure measurement and consistent device functionality.

Furthermore, Capel's 4-layer Fpc PCB has an impressive minimum aperture of 0.2mm. This small aperture size enables precise component placement during fabrication, further improving device reliability and overall performance. With meticulous attention to detail, Capel ensures that every blood pressure monitoring device built with a flexible PCB meets the highest industry standards.

Safety is paramount for medical devices, which is why Capel's 4-layer Fpc PCB design is flame retardant. Its 94V0 flammability rating ensures that the PCB can withstand and contain any potential fire hazards, minimizing risk to patients and medical professionals. This feature reflects Capel's commitment to producing high quality, safe products for the medical field.

In order to increase the lifespan and performance of Capel 4-layer Fpc PCB, it has undergone a surface treatment process called immersion gold. This treatment not only provides a protective layer against oxidation, but also ensures excellent solderability, making it easier for manufacturers to assemble PCB components. The immersion gold surface treatment significantly improves the reliability and service life of the device, reduces maintenance costs and enhances the overall user experience.

The resistance soldering color of the 4-layer Fpc PCB is black to give a stylish and professional aesthetic to its integrated medical devices. This color choice enhances the overall appearance and makes these devices more attractive to patients and medical professionals. Black also symbolizes sophistication and quality, further establishing Capel as a trusted and innovative brand in medical technology.

Stiffness is an important factor to consider when designing blood pressure monitoring devices. Capel's 4-layer Fpc PCB uses steel plate as the base material to ensure the required rigidity while maintaining flexibility. This unique combination of flexibility and rigidity enhances the durability of the device, ensuring its longevity against regular use and the potential for accidental drops.

The application of Capel's 4-layer Fpc PCB is mainly in medical equipment, especially blood pressure monitors. The PCB's excellent performance, reliability, and ability to handle complex circuit layouts make it ideal for blood pressure monitoring equipment. Its integration ensures accurate readings, providing medical professionals with valuable data for efficient diagnosis and treatment.

In summary, Capel's 4-layer Fpc PCB is revolutionizing the field of blood pressure medical devices with its advanced features and superior performance. Its multi-layer design, thin wire size, thin sheet thickness, and high-quality materials contribute to accurate readings, seamless integration, and ultimate user convenience. With Capel's flexible PCBs, medical professionals can rely on precise data analysis, and patients can benefit from accurate diagnoses and personalized treatment plans. Through a commitment to excellence and innovative solutions, Capel continues to advance medical technology, ultimately improving patient care and outcomes.

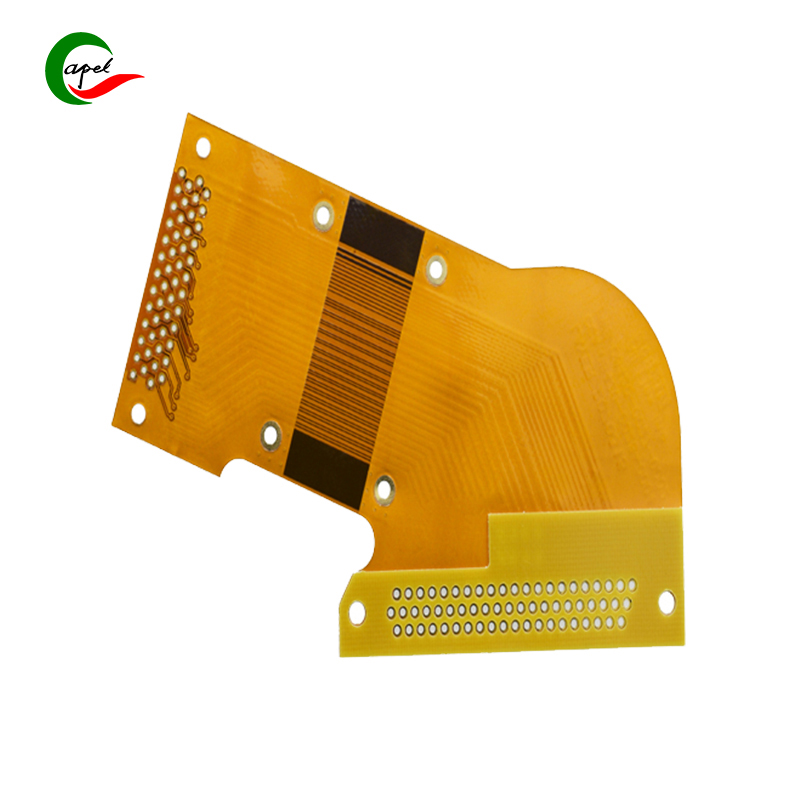

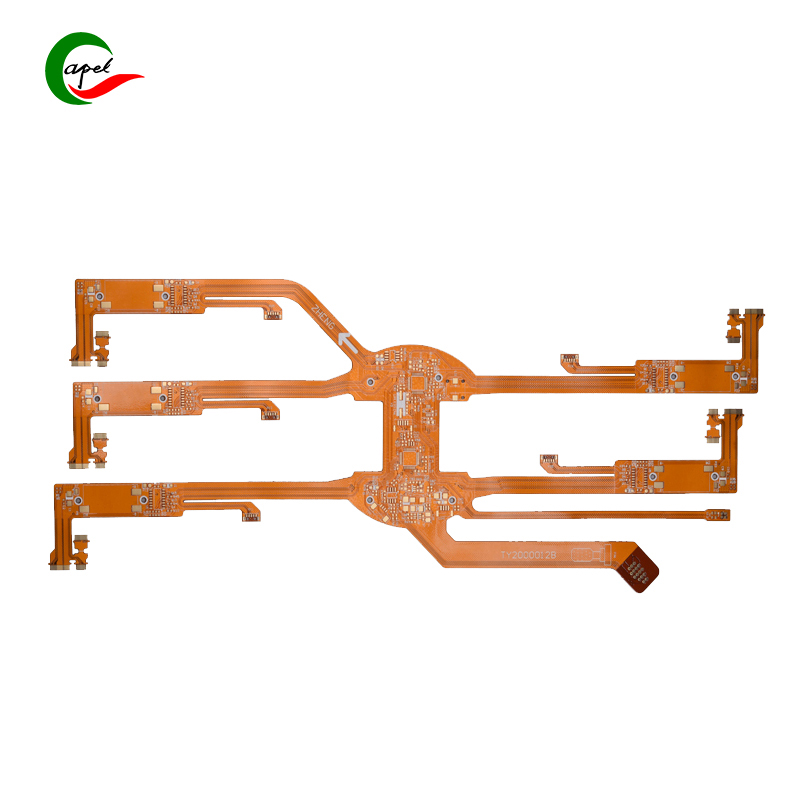

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

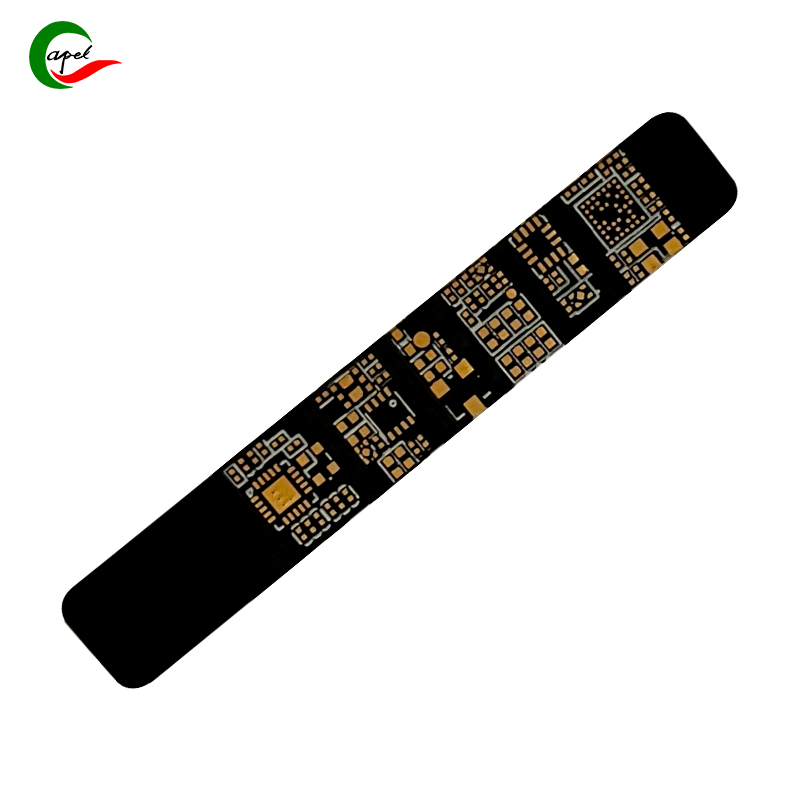

4 Layer Pcb Stackup Advanced Circuits Flex Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.