Quick Turn Pcb Fabrication Double Layer Pcb Manufacturer China

How Capel's Double Layer Pcb Provide Reliability Solutions for car gear shift knob Automakers

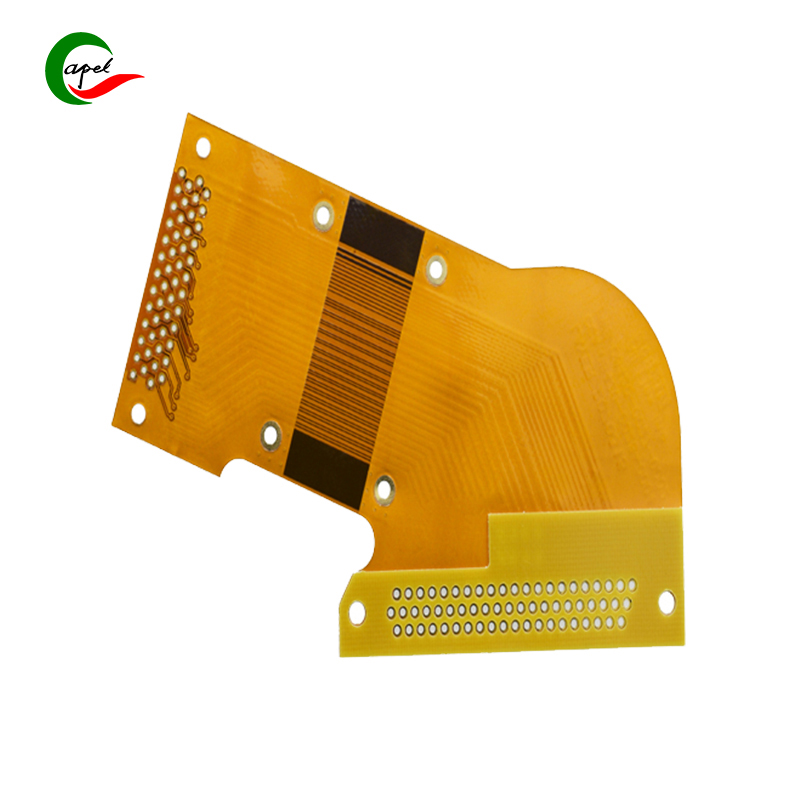

2 Layer Quick Turn Flex Pcb applicated in car gear shift knob

-Capel with 15 years of professional technical experience-

Application of Capel 2-layer flexible circuit board on automobile gear shift knob

In the automotive industry, every component plays a vital role in keeping a vehicle running smoothly and efficiently. One component that is often overlooked is the car shift knob. Insignificant as it may seem, this small, unassuming knob is responsible for seamless transitions from one gear to the next, providing a comfortable, safe ride. To make the shifting process even better, manufacturers are now turning to advanced technologies such as Capel 2-layer flexible circuit boards.

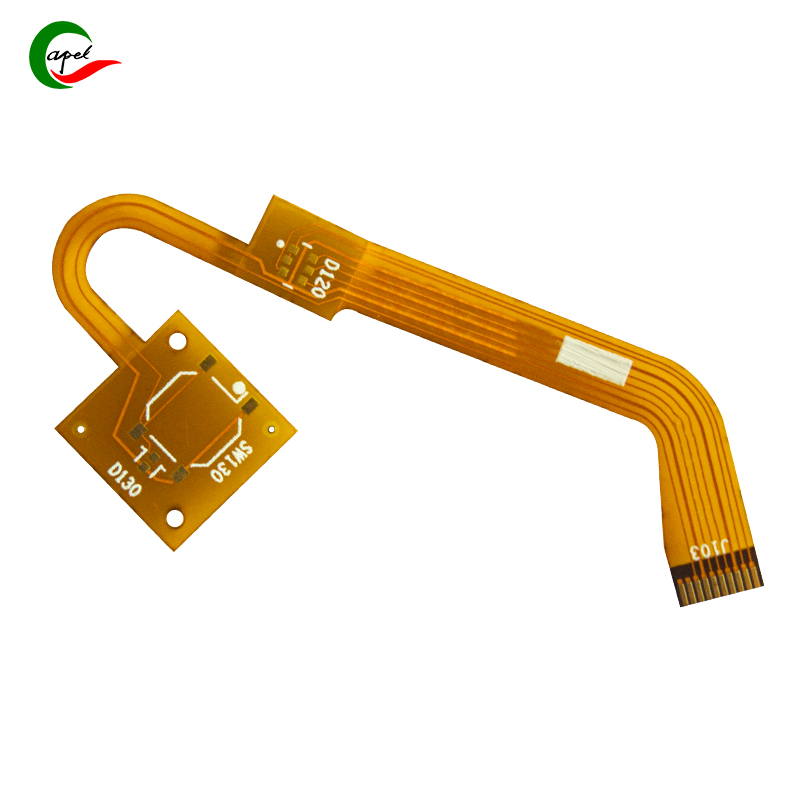

Capel 2-layer flexible circuit boards are a breakthrough innovation in automotive electronics. Specifically designed for automotive shift knobs, this flexible circuit board provides enhanced performance and durability. With its flexibility, it can easily adapt to the shape and design of the knob, making it ideal for a wide variety of car models.

A key advantage of Capel's 2-layer flex circuit boards is the ability to combine flexibility with stiffness. This unique feature ensures that the circuit board remains stable and secure within the shift knob, even during frequent and repeated use. By adopting this advanced technology, manufacturers can eliminate the risk of circuit board failure, thereby extending the life of the shift knob.

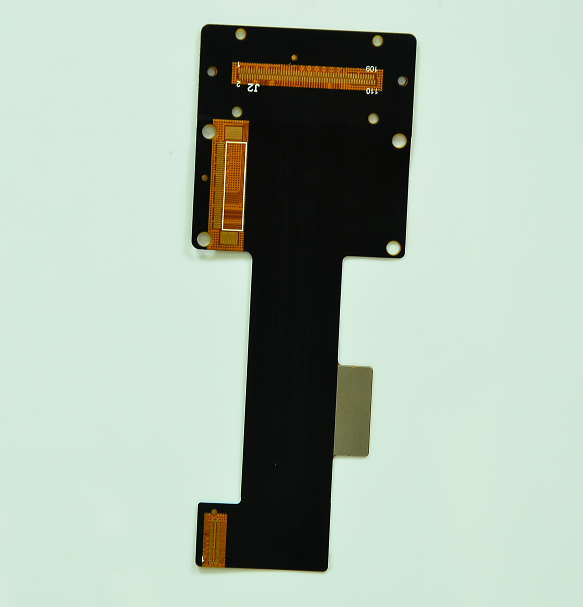

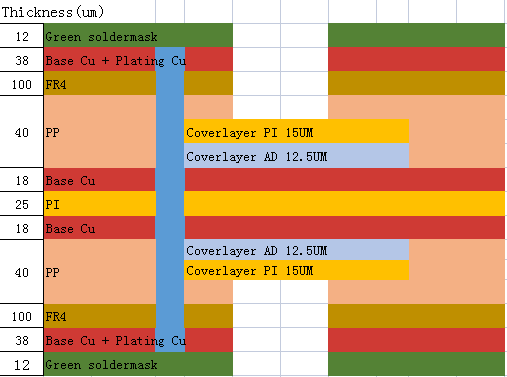

In terms of technical specifications, Capel 2-layer flex circuit boards deliver impressive numbers. It consists of two layers that allow for more efficient current and signal flow. The line width and line spacing are 0.3MM and 0.35MM respectively, providing high precision and accuracy in electrical signal transmission. The plate thickness is specified as FPC=0.15MM T=0.8MM to ensure a solid structure that can withstand the rigors of daily use.

To further enhance its performance, Capel 2-layer flex circuit boards are equipped with 1OZ copper thickness. This thicker layer of copper ensures excellent electrical conductivity, reducing the risk of signal loss or interference. The film thickness measures 50UM, adding an extra layer of protection that protects the board from environmental elements such as humidity and temperature fluctuations.

In terms of surface treatment, Capel 2-layer flexible circuit board adopts ENIG 2-3uin, which provides excellent solderability and corrosion resistance. This finish ensures reliable and long-lasting connections between the board and other components such as switches and wires. In addition, a precision tolerance of 0.1MM ensures precise positioning and alignment of the circuit board within the shift knob.

The materials used in Capel's 2-layer flex circuit boards are another notable aspect. The board is made of high-quality Panasonic material and TG150 FR-4, which has excellent thermal stability and heat resistance. This is especially important for components like the shift knob, which are often exposed to high temperatures due to their proximity to the engine. The board's ability to withstand these extreme conditions ensures reliable performance and longevity.

To ensure the highest level of quality, Capel 2-layer flex circuits undergo rigorous functional testing. This includes automated optical inspection (AOI), four-wire testing, continuity testing and copper strip inspection. These tests verify that the board meets all necessary electrical and mechanical requirements, ensuring its reliability and compatibility with the shift knob.

The application of Capel 2-layer flexible circuit boards is not limited to a specific car make or model. But it's worth mentioning that it was primarily designed for cars made in Japan. The Japanese automotive industry is known for its advanced technology and high quality standards, and the adoption of Capel 2-layer flexible circuit boards further reinforces the commitment to excellence and innovation.

In summary, Capel 2-layer flexible circuit boards are a game changer for the automotive industry, especially in the area of automotive gearshift knobs. Its unique combination of flexibility and stiffness, as well as its impressive technical specifications, make it ideal for manufacturers looking to enhance the performance and durability of shift knobs. With high-quality construction, excellent thermal stability and rigorous testing, Capel 2-layer flexible circuit boards are sure to revolutionize the driving experience of car owners around the world.

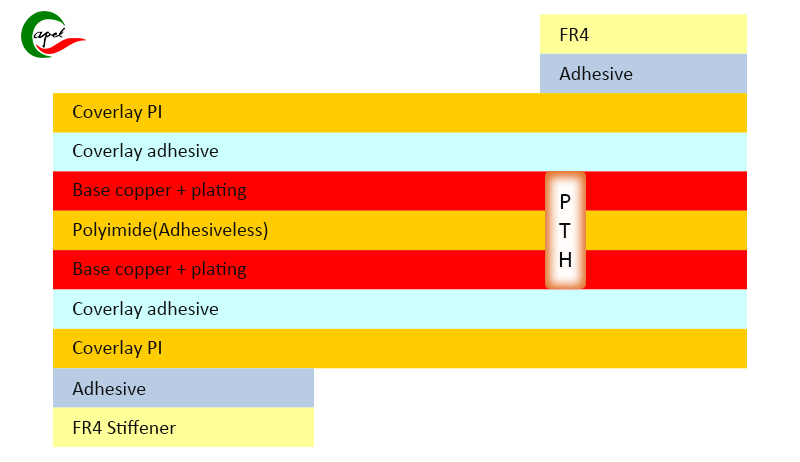

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

2 Layer Flexible Circuit Board

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.