Quick Turn Flex Pcb 3 Layer Pcb for Unmanned Vehicle Vision System

How Capel's 3-Layer Multilayer Flexible PCB Provides Reliability Solutions for Unmanned Vehicle Vision System Automakers

3 Layer Pcb applicated in Volkswagen Unmanned Vehicle Vision System

-Capel with 15 years of professional technical experience-

Capel's 3-Layer Multilayer Flexible PCB: Revolutionizing Volkswagen's Vision System for Driverless Vehicles

In the field of automotive technology, advancements are constantly being made to increase the performance and efficiency of vehicles. Capel's 3-layer multilayer flexible PCB is one such breakthrough innovation that will revolutionize Volkswagen's vision systems for driverless vehicles. This cutting-edge product offers a host of features designed to deliver exceptional functionality and performance. Let's explore how Capel's PCBs are having a major impact on the automotive industry.

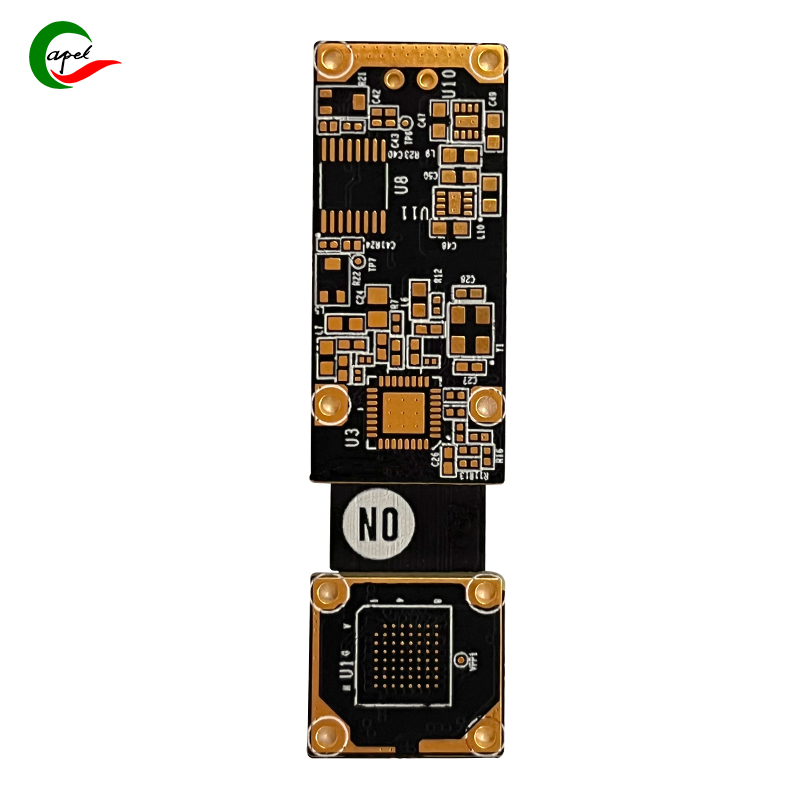

At the heart of Capel's 3-layer multilayer flex, PCB lies its electromagnetic conversion action, which plays a vital role in absorbing noise and reducing interference. Noise and interference can adversely affect vehicle vision systems, affecting their accuracy and reliability. The electromagnetic transducing action of the PCB helps to resolve these issues, ensuring that the vision systems of mass-produced autonomous vehicles operate at an optimal level.

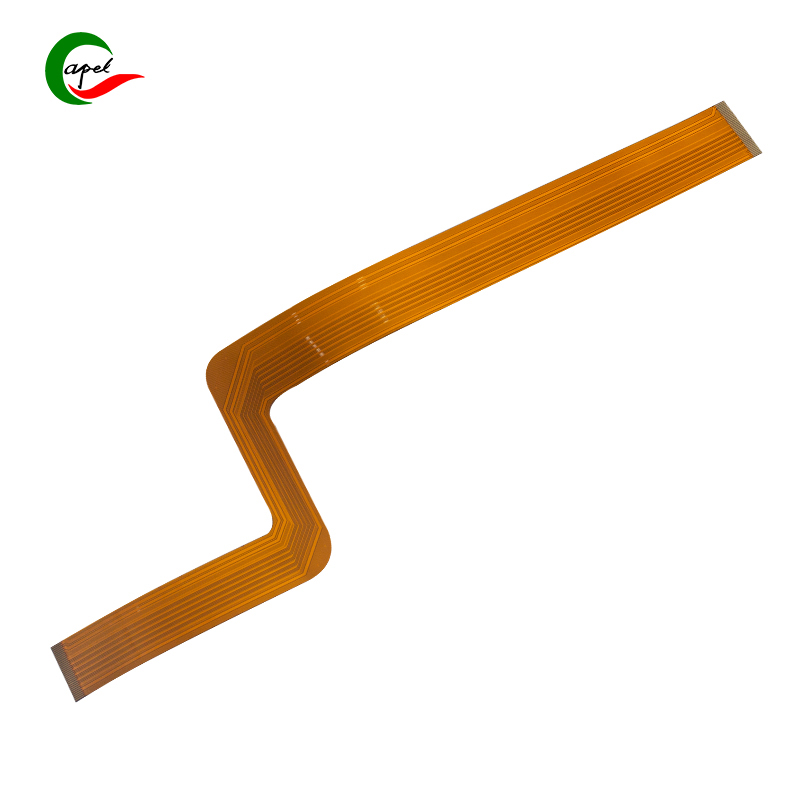

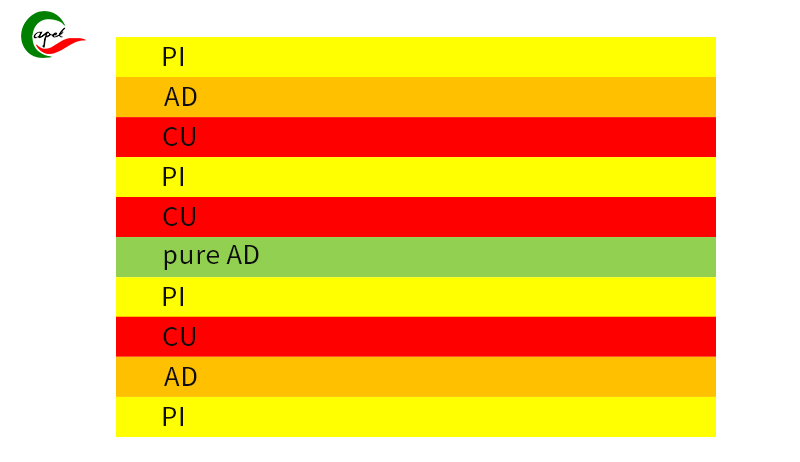

Product Type: Multilayer Flexible PCB

Capel's 3-Layer Multilayer Flex PCB is specifically designed as a multilayer flex circuit board with three layers of interconnected circuitry. This type of PCB construction has many advantages over traditional rigid PCBs, including enhanced flexibility and reduced space requirements. The board's flexibility allows for efficient installation and maintenance, making it ideal for mass-market driverless vehicle vision systems.

Number of layers: 3 layers

Capel's 3-layer multilayer flexible PCB enables efficient signal transmission and provides ample space for the complex circuitry required for mass-market driverless vehicle vision systems. By utilizing multiple layers, PCBs can accommodate complex designs while minimizing signal loss and ensuring optimum performance.

Line width, line spacing: 0.15/0.15MM

The precise line width and line spacing of Capel's 3-layer multilayer flexible PCB contribute to its excellent performance. The PCB has a line width and spacing of 0.15mm, which enables high-speed signal transmission and ensures signal integrity for the entire Volkswagen driverless car vision system. This level of precision is critical to maintaining the accuracy of the system's visual functions.

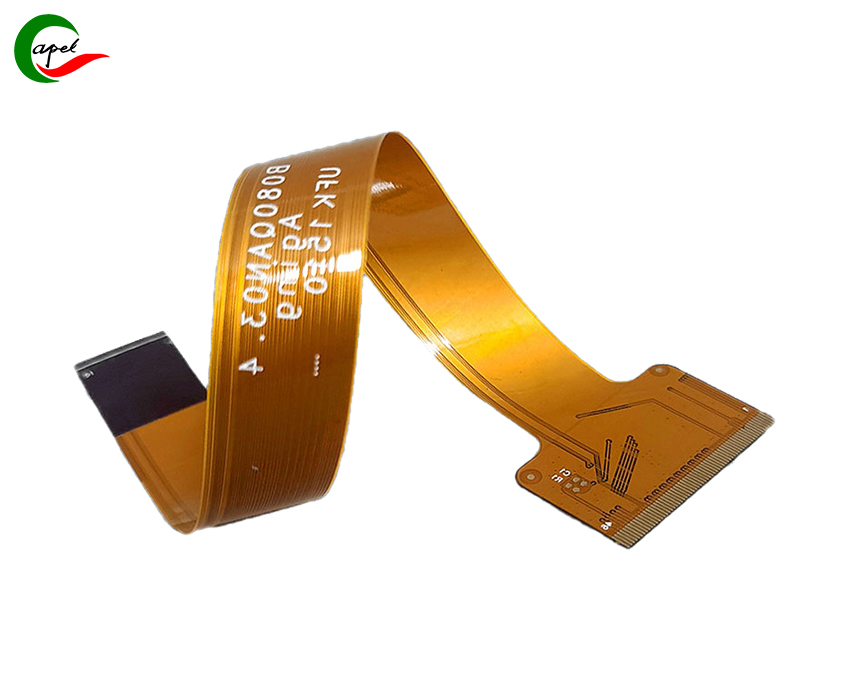

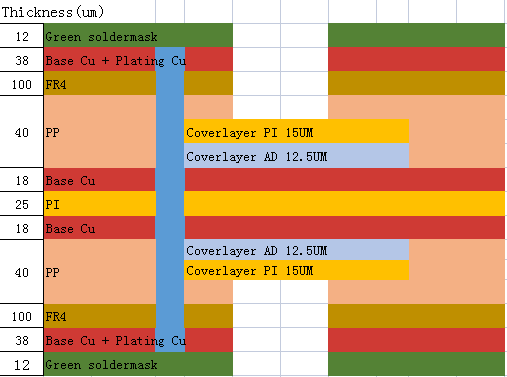

Board thickness: 0.2MM

Capel's multilayer flex PCB boards are only 0.2 mm thick, making them flexible and lightweight. The thin plate design also enables efficient heat dissipation, ensuring that the PCB operates within an optimum temperature range.

Minimum aperture: 0.15MM

An important feature of Capel's multilayer flex PCBs is their minimum aperture size of 0.15 mm. The specification allows for the precise placement of components, enabling compact and streamlined designs for vision systems in mass-produced autonomous vehicles. The small aperture size also increases the PCB's resistance to environmental factors such as dust and moisture.

Hole copper thickness: 12-15UM

Capel's 3-layer multilayer flex PCB includes vias with a copper thickness of 12-15UM. This copper layer ensures the durability and electrical conductivity of the PCB, enabling seamless electrical connections throughout the system. Carefully designed copper thickness contributes to the robustness and stability of vision systems in mass-produced autonomous vehicles.

Surface treatment: ENIG 2uin

To protect the PCB from environmental elements and mechanical stress, Capel's multilayer flexible PCBs are given a surface treatment called ENG 2U. This treatment enhances the board's resistance to corrosion and oxidation, ensuring long-term reliability and performance. The ENG 2U finish further strengthens the PCB's suitability for the harsh conditions of the automotive industry.

Copper thickness: 1OZ

The copper thickness of Capel multilayer flexible PCB is 1OZ, which provides excellent electrical and thermal conductivity. Copper thickness is consistent throughout the PCB to ensure uniform electrical signals and efficient heat dissipation. This feature will help improve the overall reliability and longevity of vision systems in Volkswagen autonomous vehicles.

Licensed material: EMS120S-200

Capel's multilayer flex PCBs are built with high-quality licensed materials, specifically EMS120S-200. These materials have been carefully selected to meet the stringent requirements of the automotive industry, ensuring PCB durability and performance. By using licensed materials, Capel guarantees the highest level of quality and reliability for Volkswagen's vision systems for autonomous vehicles.

Applicable models: Volkswagen

Capel's 3-layer multilayer flexible PCB is designed for Volkswagen brands to meet the unique requirements of their autonomous vehicle vision systems. Close cooperation between Capel and Volkswagen ensures seamless integration and compatibility, resulting in superior performance and functionality.

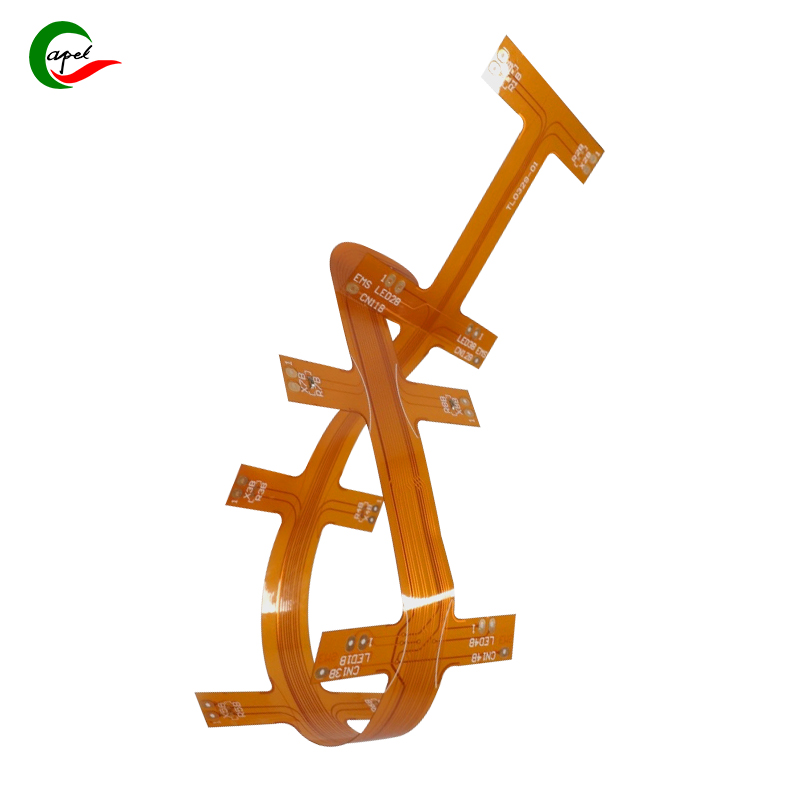

Application: Vision Systems for Autonomous Vehicles

The main application of Capel's multilayer flexible PCB is the vision system for driverless cars developed by Volkswagen. This advanced system relies on precise vision data processing to enable safe autonomous driving. Capel's PCBs play a vital role in ensuring the real-time transmission and processing of system data, thereby improving the overall safety and efficiency of vision systems for autonomous vehicles.

In conclusion, Capel's 3-layer multilayer flexible PCB ushers in a new era of innovation for Volkswagen's vision systems for autonomous vehicles. With its electromagnetic switching action, precise design specifications, and high-quality materials, this PCB revolutionized the automotive industry. Capel's commitment to excellence ensures autonomous vehicle vision systems reach their full potential, paving the way for safer, more efficient autonomous driving.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

3 Layers Multilayer Flex PCB

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.