Introduction :

Welcome to Capel’s official blog! With over 15 years of experience in the circuit board industry, Capel prides itself on providing exceptional manufacturing and supply services for regular flexible PCBs. In this article, we’ll explore every aspect of Capel’s products, from our state-of-the-art manufacturing processes to our commitment to customer satisfaction. Stay tuned as we reveal the benefits of choosing Capel for all your flexible PCB needs.

1. Understand periodic flexible PCB:

Before diving into Capel’s expertise, it’s necessary to understand the concept of periodic flex PCBs. These specialized circuit boards are designed to accommodate applications that require repeated bending, twisting and flexing. Their thin, light and flexible properties make them ideal for a variety of industries including aerospace, automotive, healthcare and consumer electronics.

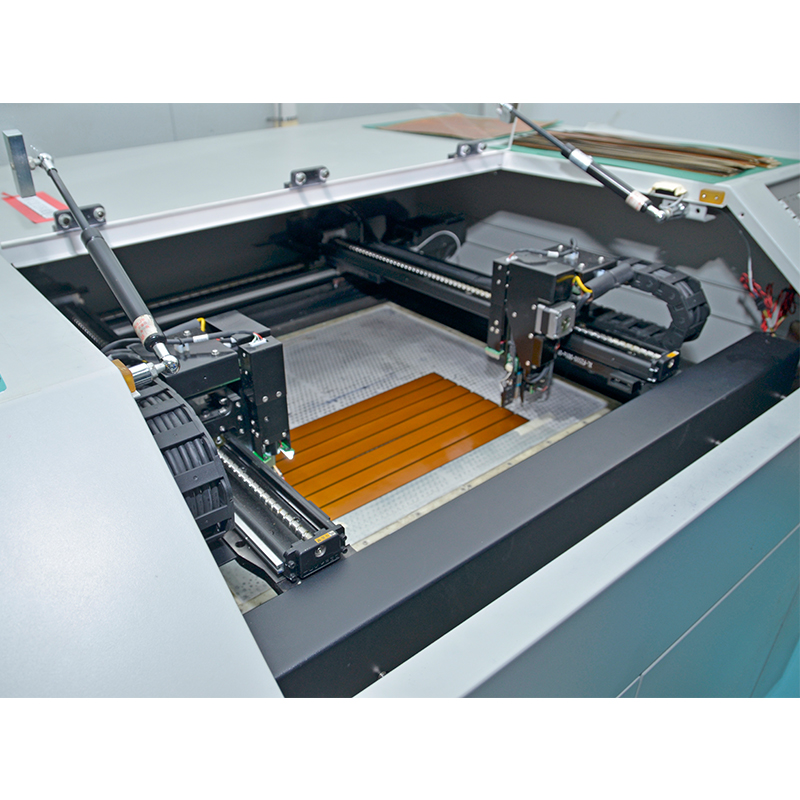

2. State-of-the-art manufacturing technology :

Capel uses cutting-edge manufacturing processes to ensure the highest quality periodic flexible PCBs. Our advanced equipment, including automated assembly lines and precision die-cutting machines, enable us to provide flexible circuit boards that meet strict industry standards.

In addition, our skilled technical staff have an in-depth understanding of the complexities of producing periodic flexible PCBs. Whether completing complex soldering tasks, implementing conductive ink printing, or executing complex designs, our team ensures quality and reliability in every product.

3. Comply with industry standards:

At Capel, we recognize the importance of adhering to industry standards to meet customer expectations. We strictly follow the International Organization for Standardization (ISO) guidelines to ensure that all aspects of our manufacturing and supply processes are of the highest standard.

Quality management is at the forefront of our operations and we have certifications including ISO 9001:2015 and ISO 13485:2016 for medical devices. By adhering to these strict standards, Capel ensures our customers receive flexible PCBs that perform flawlessly in even the most demanding environments.

4. Customization and flexibility:

At Capel, we understand that every customer’s needs are unique. To meet individual needs, we offer a wide range of customization options and maintain flexibility throughout the manufacturing and supply process.

From selecting the appropriate materials, including polyimide, polyester and adhesive systems, to determining dimensions, layer count and impedance control, Capel ensures that every aspect of the periodic flex PCB is fully compliant with the customer’s specifications. This flexibility extends to our ordering process, as we offer competitive pricing for both small and large quantities.

5. Commitment to customer satisfaction :

At the core of Capel’s success lies our unwavering commitment to customer satisfaction. We know that timely delivery, good communication, and excellent support are crucial to building lasting relationships with our customers.

Our dedicated customer service team is always available to answer questions, provide regular progress updates and provide technical assistance. By fostering transparent, collaborative partnerships, Capel ensures every customer has a seamless experience throughout the manufacturing and supply process.

Conclusion:

Capel’s 15 years of experience, state-of-the-art manufacturing processes, adherence to industry standards, customization options and commitment to customer satisfaction make us the first choice for regular flexible PCB manufacturing and supply. Whether your company operates in aerospace, automotive, healthcare or consumer electronics, choosing Capel guarantees superior quality and reliability.

Work with Capel today and experience the unparalleled expertise and passion we bring to every project. Please contact our team to discuss your needs and let us work together to drive innovation in the cyclic flex PCB space.

Post time: Nov-04-2023

Back