This blog explores why using rigid-flex PCBs is preferable to flexible PCBs in electronics projects and how they can help enhance performance and functionality.

Introduce:

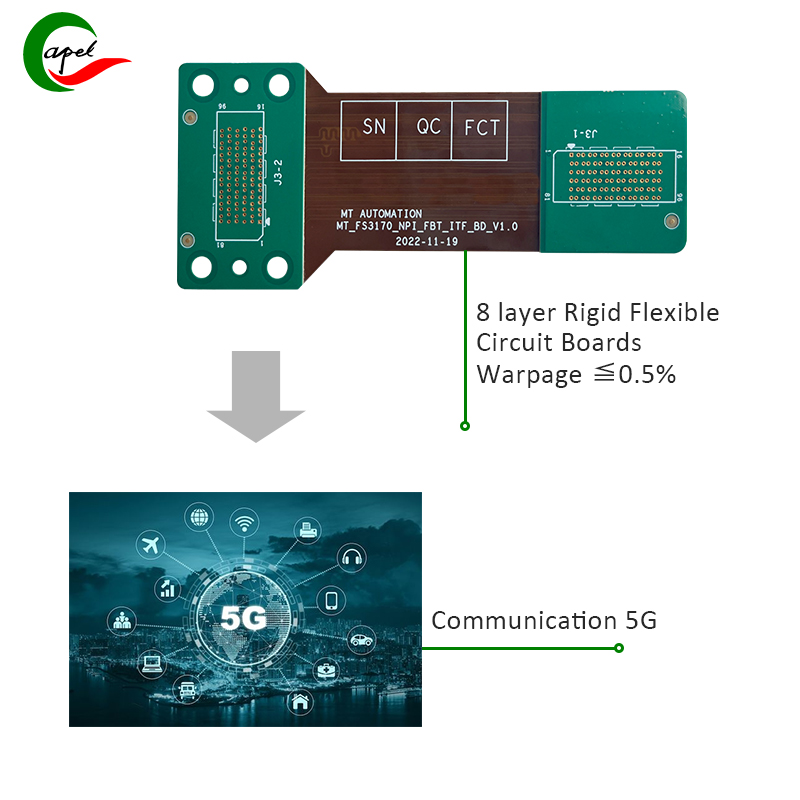

In today’s rapidly evolving technological environment, there is a constant need to improve the efficiency and flexibility of electronic devices. Printed circuit boards (PCBs) play a vital role in the development and performance of these devices. Among the different types of PCBs available, rigid-flexible PCB and flexible PCB are popular for their unique characteristics. However, when it comes to electronic projects that require a combination of durability and versatility, rigid-flex PCBs have proven to be the best choice.

Part 1: Durability and Reliability

One of the main advantages of using rigid-flex boards in electronics projects is their exceptional durability and reliability. Unlike traditional flexible PCBs, which are composed of a single layer of flexible material, rigid-flex PCBs mix rigid and flexible layers together. The combination of rigid and flexible materials increases resistance to environmental stresses, mechanical strains and vibrations. This makes rigid-flex PCBs more suitable for applications that are repeatedly bent, folded, or subjected to strong mechanical stress.

Section 2: Space Optimization

Another major reason to choose rigid-flex PCBs for electronics projects is their space optimization capabilities. As electronic devices become smaller and more compact, designers need innovative solutions to fit all necessary components without compromising performance. Rigid-flex PCBs eliminate the need for connectors, cables, and additional interconnects, allowing for seamless integration of components. By eliminating these extra components, designers can achieve significant space savings, resulting in sleeker, more efficient electronic devices.

Part 3: Enhancing Signal Integrity

Signal integrity is a critical factor in ensuring the proper operation and performance of electronic devices. Rigid-flex PCBs provide superior signal integrity compared to flexible PCBs. The rigid layer in a rigid-flex PCB acts as a shield, preventing electromagnetic interference (EMI) and crosstalk between different electronic components. This results in better signal transmission, reduced noise, and improved overall performance. Additionally, rigid sections within the PCB reduce the risk of signal impedance mismatches, allowing for better impedance control and reduced signal reflections.

Part 4: Simplifying the Assembly Process

The assembly process of electronic projects is often time-consuming and complex. However, by using rigid-flex printed circuit boards, the assembly process is simplified, reducing production time and costs. Integrates rigid and flexible parts within the same board, eliminating the need for separate components and connectors. This streamlined assembly process not only reduces the number of steps required, it also minimizes the risk of errors and increases overall production efficiency.

Section 5: Cost Efficiency

Contrary to popular belief, choosing a rigid-flex PCB can be a cost-effective solution for electronics projects. While the initial cost of designing and manufacturing rigid-flex PCBs may be higher compared to traditional flexible PCBs, the long-term benefits outweigh the initial investment. Rigid-flex printed circuit boards eliminate the need for multiple interconnects and cables, thereby reducing overall manufacturing and production costs. Additionally, the durability and reliability of these boards reduce maintenance and replacement costs over the extended life of the equipment.

In conclusion:

In summary, rigid-flex PCBs provide an ideal solution for electronic projects that require durability, space optimization, enhanced signal integrity, simplified assembly, and cost-effectiveness. Their unique combination of rigid and flexible materials provides exceptional durability and reliability, ensuring resistance to mechanical stress and environmental factors. Rigid-flex PCBs optimize space utilization and enhance signal integrity, improving the performance and functionality of electronic devices. Additionally, simplified assembly processes and long-term cost efficiencies make rigid-flex PCBs a favorable choice for electronic projects. In an era of rapidly evolving technology, leveraging the advantages of rigid-flex PCBs can provide a competitive advantage in electronics design and manufacturing.

Post time: Oct-11-2023

Back