Shenzhen Capel Technology Co, Ltd is leading the development of the PCB industry. And it has won the trust of customers for its excellent team, industry experience production capacity, and commitment to quality.

The following will introduce Capel in detail from its 15 years of experience in the circuit board industry, Production Capability, R&D Team, Circuit Board Types, SMT Assembly Service, PCB Prototypes, PCB Assembly Service, Application Case Experience, Customer Service and Quality Control.

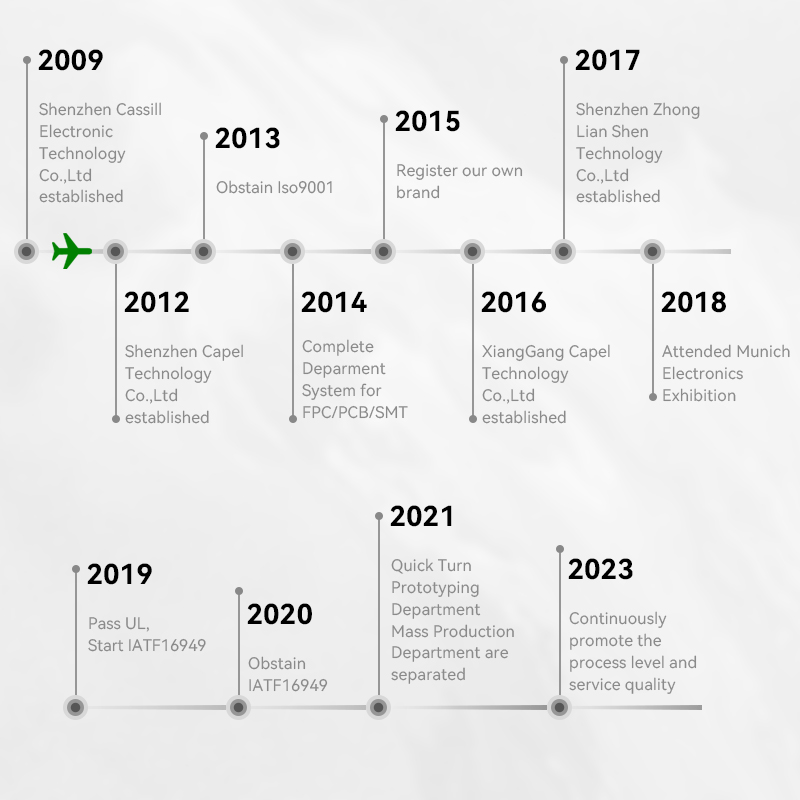

Capel with 15 years of Experience in the Circuit Board Industry

Shenzhen, Capel Technology Co, Ltd. (hereinafter referred to as Capel) was established in 2009 and has accumulated 15 years of professional technology and industry experience in the PCB circuit board industry. During the 15 years of development, Capel has solved thousands of problems with circuit board projects for more than 200,000 customers who deeply trust Capel with strict production technology, advanced process capabilities, and continuous innovation of professional technology, and promoted the successful completion of the customer’s project, so that the customer quickly seized the market opportunity.

Adhering to the service concept of “integrity wins the world, quality creates the future”, our company Capel has developed into a comprehensive high-tech enterprise with three factories and more than 1,500 employees for printed circuit boards and PCB SMT assembly. Capel focuses on the R&D, production, and sales of various PCBs, and has an impressive range of service products to meet the needs of different industries.

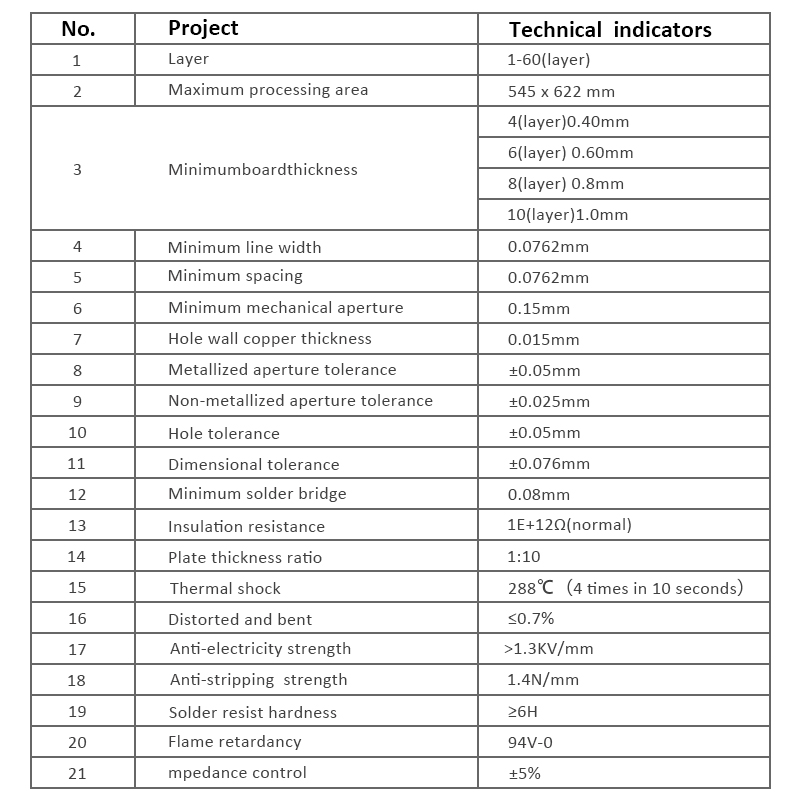

Printed Circuit Board Production Capability

The company’s main factory has 500 employees and a production and office area of more than 10,000 square meters, which is a testament to its manufacturing strength. With such abundant resources, Capel is able to produce more than 450,000 square meters of flex and rigid-flex PCBs per month. This impressive production capacity ensures that the company can efficiently meet the needs of its global customer base. In addition to the main factory, Capel also operates two subsidiaries: Shenzhen ZhongLianShen Technology Co, Ltd. and Shenzhen Capel Technology Co, Ltd. (l). further enhancing its production capacity. Shenzhen ZhongLianShen Technology Co.,Ltd. was established in 2017, focusing on the production of rigid PCB, with a monthly production capacity of 80,000 square meters.On the other hand, Shenzhen Capel Technology Co, Ltd. (ll), founded in 2012 specializes in assembly and has a staggering capacity of 150 million components per month.

Together with the main factory, these subsidiaries enable Capel to provide comprehensive solutions across different PCB categories.

Professional R&D Team for PCB Service

What really sets Capel apart is its exceptional team. With more than 200 engineers and researchers and more than 100 team members with over 15 years of experience in the PCB industry, Capel has the knowledge and expertise to ensure top-notch product quality and customer satisfaction, which makes Capel able to take on complex and challenging PCB projects with ease. Our professionals with extensive industry experience underscore their dedication to providing cutting-edge and reliable solutions to our clients.

Circuit Board Types and SMT Assembly Service

Capel’s high-density, high-precision PCB circuit board’s mature technology has been highly recognized by our customers and has won the trust of our customers for its excellent quality, reliability, and performance.

Our company specializes in the production of various PCB types. including flexible PCB, rigid-flex PCB, multi-layer PCB single/double-sided circuit board, hollow board, HDI board, Rogers PCB, RF PCB,metal core PCB, special process board, ceramic PCB SMT assembly and PCB prototyping services.

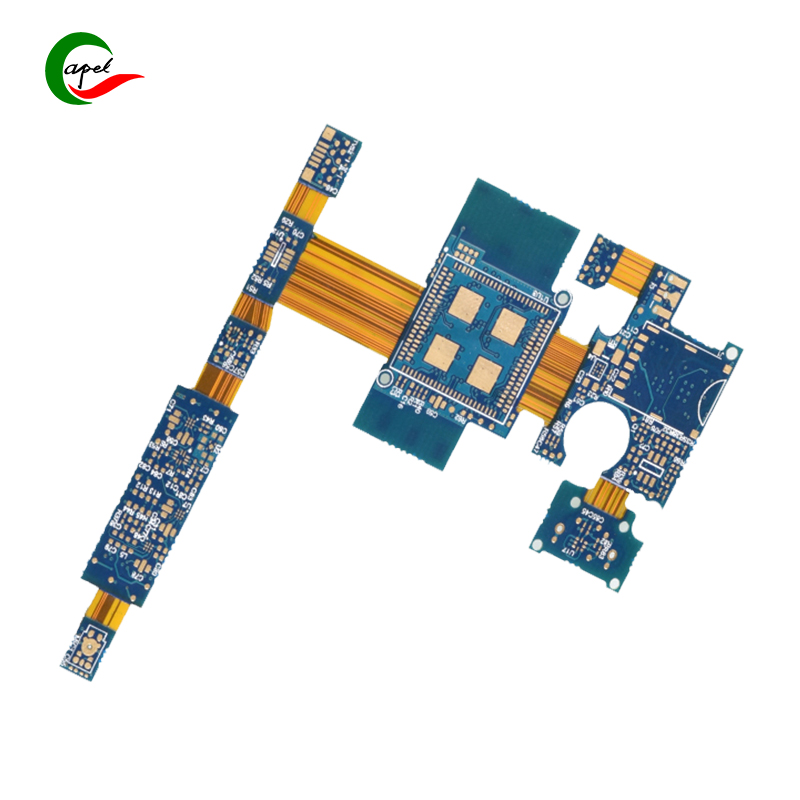

Flexible PCBs from manufactured by Capel are designed to bend and conform to the shape of the device, making them suitable for applications requiring flexibility and compactness.

Rigid-flex PCBs combine the advantages of rigid and flex boards, offering enhanced durability and design flexibility.

Multi-layer PCBs made by Capel can achieve high circuit density, enabling more complex electronic designs. These boards are widely used in applications requiring advanced functionality and miniaturization.

Our company also has extensive experience in manufacturing single/double-sided circuit boards typically used in simpler electronic devices.

Our hollow boards provide lightweight and cost-effective solutions for certain applications.

HDl boards utilize advanced technologies such as micro vias, blind, and buried vias to achieve high-density interconnects. These boards are suitable for high-performance applications requiring miniaturization and

high speed.

Rogers PCBs from Cape! are designed with specialized high-frequency laminates ideal for RF and microwave applications requiring signal integrity and low loss.

Metal core PCBs supplied by Cape! have a metal core layer for excellent heat dissipation. These boards are commonly used in applications such as power electronics, aerospace, and automotive industries.

We are also able to manufacture special process boards such as edge plating, gold finger, and impedance-controlled boards to meet specific customer requirements.

In addition, our company offers ceramic PCBs, which have excellent electrical insulation and temperature resistance, making them suitable for high-power and high-temperature applications.

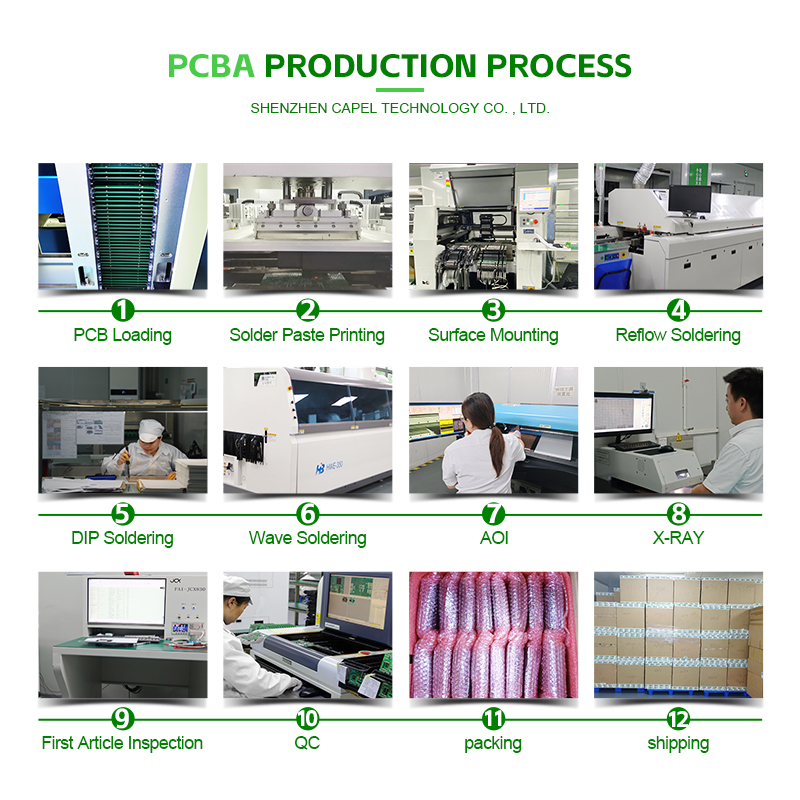

Capel’s SMT assembly services ensure efficient and reliable assembly of components onto PCBs, enabling rapid prototyping and production.

Quick Turn PCB Prototypes and Prototype PCB Assembly Service

Capel Provides Quick Turn PCB Prototype and Fast Turn SMT PCB Assembly

Quick Turn Reliable PCB Prototype and PCB Assembly Prototyping:

. 24 Hours quick turn pcb prototype

. 24×7 Online technical sales service

. Gerber file evaluation before production

. Al-round and fast logistics service support

. 1-2 Days quick turn pcb assembly prototype

. 24-hour Prototyping, the delivery time of small-batch is about 5 days.

Circuit Board Application Case Experience

Capel’s rich case experience and mature circuit board technology have established a good record of providing valuable solutions to customers in different industries. With an extensive service case covering more than 100 areas, Capel has developed expertise in meeting challenges and industry-specific requirements.

Medical devices: our circuit board technology plays an important role in the medical device industry, which provides high-reliability, high-density, and miniaturized circuit booards to meet the refinement and high-reliability requirements of medical equipment.

Internet of Things (IOT): The IOT industry requires a large number of sensors and device connections, and has high requirements for the integration and stability of circuit boards.Our technological innovation can provide high-density, multi-layer circuit board design, and high reliability and stability suitable for IOT devices.

Electronic Communications: In the telecommunications industry, high-speed data transmission and signal quality are critical. Our circuit board technology and innovative solutions can provide high-performance, low-noise, and low-cost circuit boards to meet the needs of high-speed communication equipment.

Consumer electronics: Our company’s circuit board technology is widely used in consumer electronics products, including smartphones, tablets, wearable devices etc. And it can provide highly customized circuit board design and complete solutions to meet the diverse needs of consumer electronics products.

Aerospace: Our company circuit board technology has withstood the harsh environment and reliability tests in the aerospace field, which can provide circuit boards suitable for high temperature, low temperature, radiation, and other special environments to meet the high-reliability requirements of the aerospace field.

Automotive: Capel’s circuit board technology provides key solutions for the automotive industry. And it can provide circuit boards suitable for complex electronic systems and high-vibration environments to meet the requirements of automotive electronic technology.

Military: In the military field, high reliability and long-term stability are critical. Capel’s circuit board technology can provide high density, high reliability. anti-interference, and anti-vibration characteristics in military applications.

Industrial control: The field of industrial control requires reliable control systems and communication equipment. Our company can provide circuit board solutions that meet specific requirements to ensure the stability and reliability of industrial control equipment.

Artificial intelligence: The artificial intelligence industry has high requirements for big data processing and computing power. Capel’s circuit board technology can provide high-performance, high-speed, and low-power solutions to meet the needs of artificial intelligence applications.

Electric Vehicles: The electric vehicle industry presents challenges for energy conversion and storage. Our company’s circuit board technology can provide highly customized solutions to meet the high-performance requirements of electric vehicles.

Capel’s professional technology and high-precision printed circuit boards solve the specific challenges of many industries, ensure customer satisfaction, and serve as medical devices, Internet of Things, drones, aviation, automotive, telecom, consumer electronics, military, aerospace, industrial control, artificial intelligence, electric vehicles, etc Contributed to technological advancements in fields.

Capel Customer Service Concept

As a company, Capel adheres to a strong service philosophy based on integrity and quality. We firmly believe that integrity is the foundation of success and that quality is the key to creating a prosperous future. This philosophy guides every aspect of our operations and drives us to provide technical expertise and high-precision printed circuit boards to customers worldwide.

Capel’s commitment to circuit board industry expertise and customer service has set us apart and earned us a solid reputation with customers worldwide. Capel pays attention to integrity and quality, adhering to the belief of “integrity wins the world quality creates the future“, and has successfully served more than 200,000 customers from more than 250 countries. The basis of our success lies in our application of technical expertise and the development of high-precision printed circuit boards. Our dedication to staying at the forefront of industry advancement ensures we can provide cutting-edge solutions to our customers’ circuit board needs. By continuously investing in research and development, Capel is able to deliver innovative products that meet the highest quality and performance standards.

ln addition to its commitment to technology, Capel takes customer service very seriously. We understand that building strong relationships with clients is the key to long-term success. By providing personalized support and open communication, we ensure that each client’s unique needs are met with precision and efficiency. Our well-trained and experienced team is always ready to provide guidance, technical expertise, and timely assistance to guarantee customer satisfaction. Our global reach is a testament to our commitment to meeting the diverse needs of customers from different countries and cultures. Operating in more than 250 countries, we have proven our ability to adapt to local market conditions, regulations, and customer preferences. This global presence further reinforces our commitment to supplying high-quality circuit boards that meet the needs of customers around the world. As we continue to expand our presence in the circuit board industry, our emphasis on technical expertise and customer service will no doubt continue to be the foundation of our success. By consistently delivering first-class products and memorable experiences, Capel will further strengthen its reputation and solidify its position as a trusted leader in the industry.

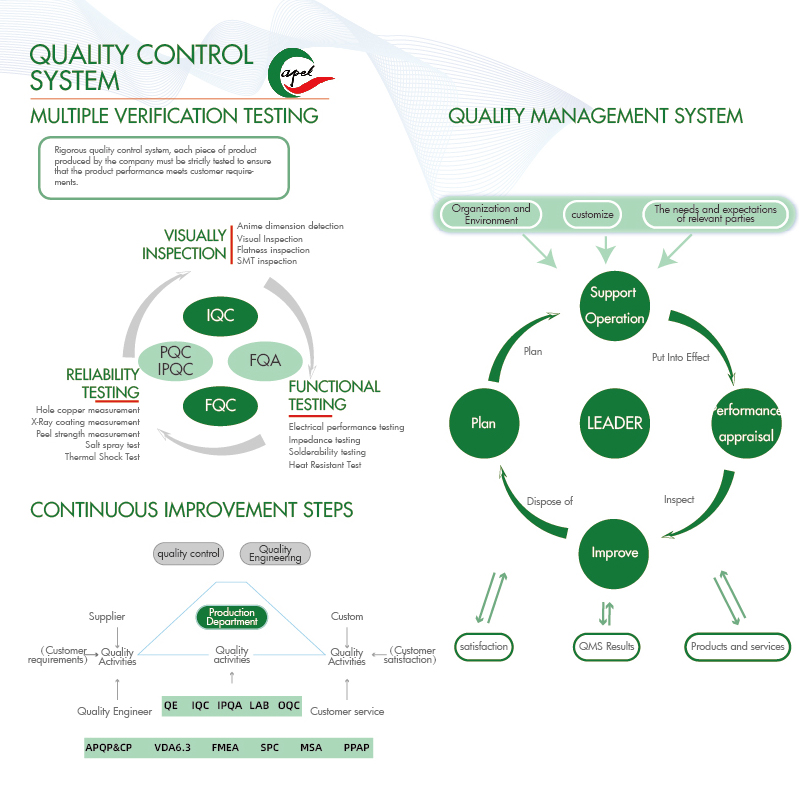

PCB Production in Strictly Quality Control

Quality control is of paramount importance to Capel. Every product produced by the company must undergo strict testing to ensure quality. Strict and well-improved quality control system, lQC(Incoming Quality Control), IPOC(ln-process Quality Control)/FAl test, Visual Inspection after reflow oven/AOl, Visual Inspection before reflow oven, QA random inspection, OQC (Out-going Quality Control), High tech PCB Assembly service(SM/DIP line),Professional components sourcing, Innovative programming and function test.

We hold ISO 14001:2015, ISO 9001:2015, and IATF16949:2016 certifications ensuring our operations comply with internationally recognized standards. Additionally, our products are UL and ROHS-marked, further demonstrating our commitment to providing safe, compliant PCB solutions. Capel’s commitment to maintaining high-quality standards and certifications not only guarantees the reliability of its products but also reassures customers of their commitment to excellence.

Capel’s success is also attributed to its strong research and development capabilities. With a total of 16 utility model patents and invention patents, Capel continues to innovate and push the boundaries of PCB technology. By investing in research and development, our company is always at the forefront of the industry, ready to meet the changing needs of customers and contribute to the progress of various industries.

Trustworthy PCB Maker

To sum up, Capel PCB is an industry-leading comprehensive high-tech enterprise specializing in the production and sales of various PCBs.With our expertise in flexible PCB, rigid-flex PCB, multi-layer PCB, single/double-sided circuit board, hollow board HDI board, Rogers PCB, RF PCB, metal core PCB, and special process board, we are committed to providing Top-of-the-line – a top-notch solution for your electronics needs.

All in all, Shenzhen Capel Technology Co., Ltd has become a leader in the PCB industry with its professional and experienced team, extensive production capabilities, diverse service offerings, commitment to quality, and focus on research and development. Our comprehensive solutions meet the needs of various industries around the world. With a proven track record and industry recognition, Capel continues to uphold the philosophy of integrity and quality service to ensure customer satisfaction and a prosperous future.

Choosing Shenzhen Capel Technology Co, Ltd. means choosing excellence, reliability and innovation. With rich expertise and cutting-edge manufacturing capabilities, we have earned a solid reputation in the industry. Whether your next project requires a flex PCB rigid PCB or a rigid-flex PCB, we believe in our ability to provide products that meet and exceed your expectations.

CONSULT A PCB THAT SUITS YOUR PROJECT

Capel manufactures Flex PCB/Rigid-Flex PCB/Rigid PCB/DIP/SMT with 15 years’ experience with our professionalism.

Contact us today to learn more about our services and discuss how we can help bring your electronic designs to life. Experience the superior quality and reliability of our PCB with Shenzhen Capel Technology Co., Ltd.

Post time: Aug-12-2023

Back