Capel, a professional circuit board manufacturer, has been serving various industries for the past 15 years. Capel has a strong reputation for providing customers with high-quality rapid PCB prototyping and facilitating volume production, playing a key role in ensuring countless projects successfully reach the market. In this blog post, we’ll delve into the world of PCB prototypes and explore the maximum temperature ratings they can withstand, revealing the innovative solutions Capel offers.

PCB prototypes are an integral part of the electronics industry as they allow engineers and designers to validate their product concepts and test their functionality before proceeding to mass production. This critical step ensures that any potential issues or defects are identified and corrected early, saving time and resources in the long run.

A key consideration when prototyping a PCB is its ability to withstand high temperatures. Temperature is an important factor because it directly affects the performance and reliability of electronic components. Therefore, knowing the maximum temperature rating of your PCB prototype is critical to ensuring its durability and functionality.

The maximum temperature rating of a PCB prototype is determined by a variety of factors, including the materials used, the types of components soldered to the board, and the intended application of the final product. Among these factors, material selection plays a vital role.

Capel leverages its extensive project experience and commitment to excellence to carefully select high-quality materials for its PCB manufacturing process. They understand that different applications may require different temperature ratings and therefore provide customized solutions to meet these requirements.

For example, Capel offers PCB prototypes with maximum temperature ratings up to 150°C for many industrial applications. This high-temperature capability ensures the prototype can withstand extreme conditions, guaranteeing long-term functionality and reliability in demanding environments.

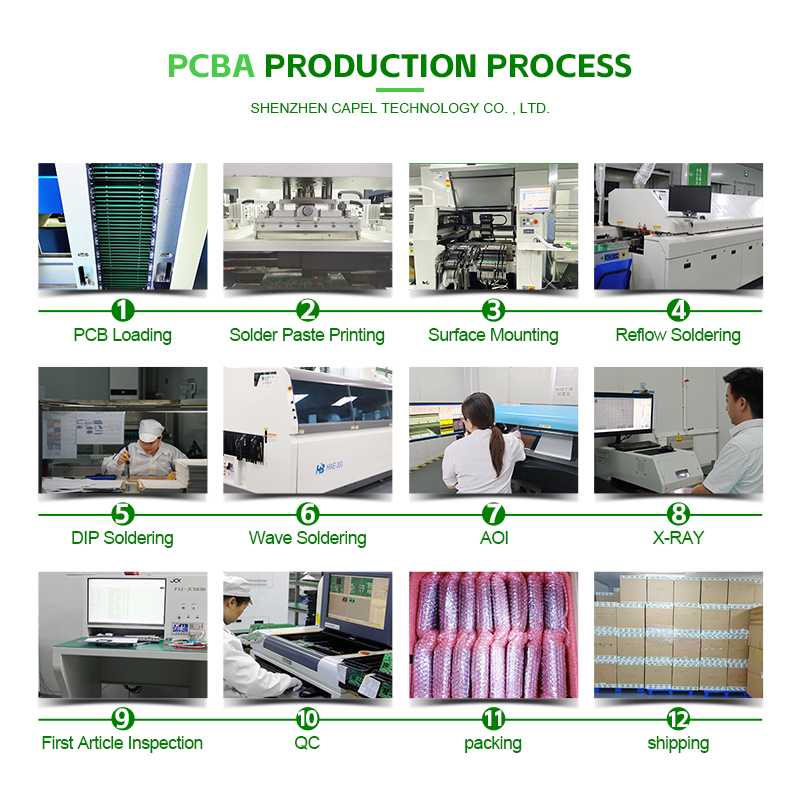

In addition, Capel utilizes advanced manufacturing techniques and quality control procedures to ensure that its PCB prototypes meet the highest standards. Strict testing and inspection are carried out throughout the production process to discover any potential weaknesses or failures so that timely adjustments and improvements can be made.

It is important to note that the maximum temperature rating of a PCB prototype is not a fixed value in all cases. Ratings may vary based on factors such as copper layer thickness, type of solder mask used, and the presence of any other protective coatings. Capel understands these nuances and works closely with clients to determine the best specifications for their unique projects.

Additionally, Capel’s expertise extends beyond PCB prototyping. They have become a reliable partner in mass production, contributing to the timely introduction of various electronic products into the market. 15 years of accumulated project experience allows Capel to fine-tune manufacturing processes and optimize efficiency without compromising quality.

In summary, the maximum temperature rating of a PCB prototype is a critical consideration in ensuring the long-term functionality and reliability of your electronic product. Capel leverages its extensive project experience and commitment to excellence to provide customized solutions with maximum temperature ratings up to 150°C. By carefully selecting high-quality materials, utilizing advanced manufacturing techniques, and conducting rigorous testing, Capel ensures that its PCB prototypes meet the highest standards. With Capel as your trusted partner, you can confidently navigate the complex world of PCB prototyping and bring your projects to market smoothly.

Post time: Oct-17-2023

Back