let’s delve into the manufacturing process of flexible circuits and understand why they are widely used in various industries.

Flexible circuits, also known as flexible printed circuits or FPCs, are popular across various industries. From consumer electronics to healthcare devices, flexible circuits have revolutionized the way electronic components are designed and manufactured. As the demand for compact and lightweight electronic devices continues to increase, it is critical to understand the manufacturing process of flexible circuits and how they have become an integral part of modern technology.

Flex circuits are essentially a combination of multiple layers of flexible material, such as polyester or polyimide, onto which conductive traces, pads, and components are mounted. These circuits are flexible and can be folded or rolled up, making them ideal for applications where space is limited.

1. Design layout in flex circuit manufacturing:

The first step in manufacturing a flexible circuit is the design and layout process. Engineers and designers work closely together to create layouts that meet the specific requirements of the application. Layout includes the placement of conductive traces, components, and any additional features that may be needed.

2. Material selection in flex circuit fabrication:

After the design phase, the next step is to select the appropriate materials for the flexible circuit. Material selection depends on factors such as required flexibility, operating temperature, and required electrical and mechanical properties. Polyimide and polyester are commonly used materials due to their excellent flexibility and thermal stability.

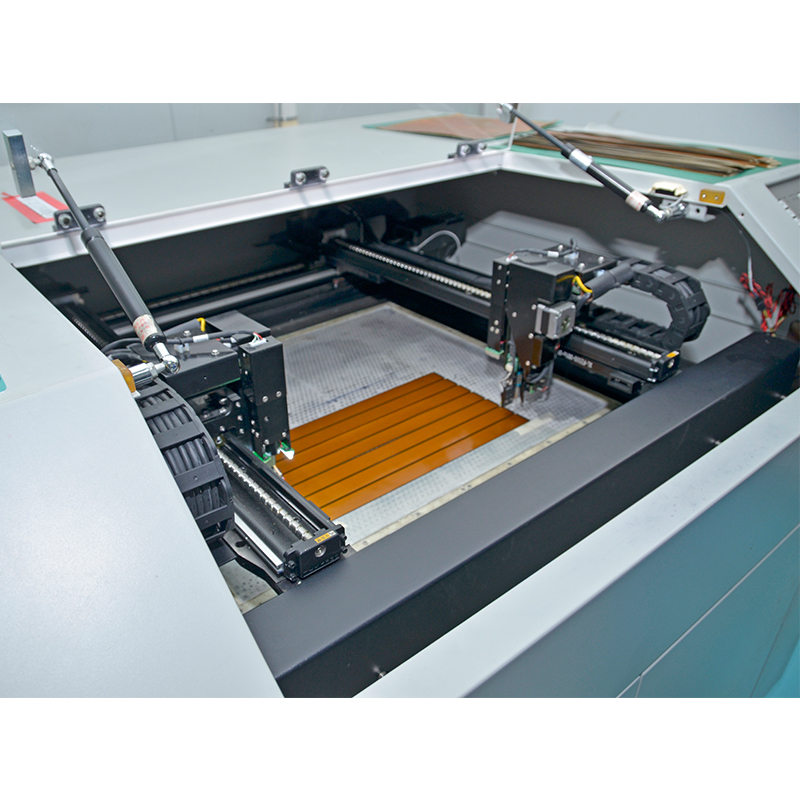

3. Production of base substrate in flex circuit making:

Once the material is selected, fabrication of the base substrate begins. The substrate is usually a thin layer of polyimide or polyester film. The substrate is cleaned, coated with adhesive, and laminated with conductive copper foil. The thickness of the copper foil and substrate can vary depending on specific application requirements.

4. Etching and laminating in flex circuit production:

After the lamination process is complete, a chemical etchant is used to etch away the excess copper foil, leaving the desired conductive traces and pads. Control the etching process by using an etch-resistant mask or photolithography techniques. Once the etching is complete, the flexible circuit is cleaned and prepared for the next stage of the manufacturing process.

5. Parts assembly in flex circuit manufacturing:

After the etching process is complete, the flexible circuit is ready for component assembly. Surface mount technology (SMT) is commonly used for component placement as it enables precise and automated assembly. Apply solder paste to the conductive pads and use a pick-and-place machine to place components. The flex circuit is then heated, causing the solder to adhere to the conductive pads, holding the component in place.

6. Testing and inspection in flex circuit manufacturing:

Once the assembly process is complete, the flex circuit is thoroughly tested and inspected. Electrical testing ensures that conductive traces and components are functioning as expected. Additional tests, such as thermal cycling and mechanical stress testing, can also be performed to evaluate the durability and reliability of flexible circuits. Any flaws or issues found during testing are identified and corrected.

7. Flexible coverage and protection in flex circuit manufacturing:

To protect flexible circuits from environmental factors and mechanical stress, flexible coverings or protective layers are applied. This layer can be a solder mask, a conformal coating, or a combination of both. The covering enhances the durability of the flex circuit and extends its service life.

8. Final inspection and packaging in flex circuit manufacturing:

After the flex circuit has gone through all necessary processes, it undergoes a final inspection to ensure it meets the required specifications. Flexible circuits are carefully packaged to protect them from damage during shipping and storage.

In summary, the manufacturing process of flexible circuits involves several complex steps, including design, material selection, fabrication, assembly, testing, and protection. The use of modern technology and advanced materials ensures that flexible circuits meet the demanding requirements of various industries. With their flexibility and compact design, flexible circuits have become an important part of the development of innovative and cutting-edge electronic devices. From smartphones to medical devices, flexible circuits are changing the way electronic components are integrated into our daily lives.

Post time: Sep-21-2023

Back