Introduction

In this blog post, we aim to uncover the secrets behind the lifespan of these unique PCBs and shed light on what factors influence their longevity.

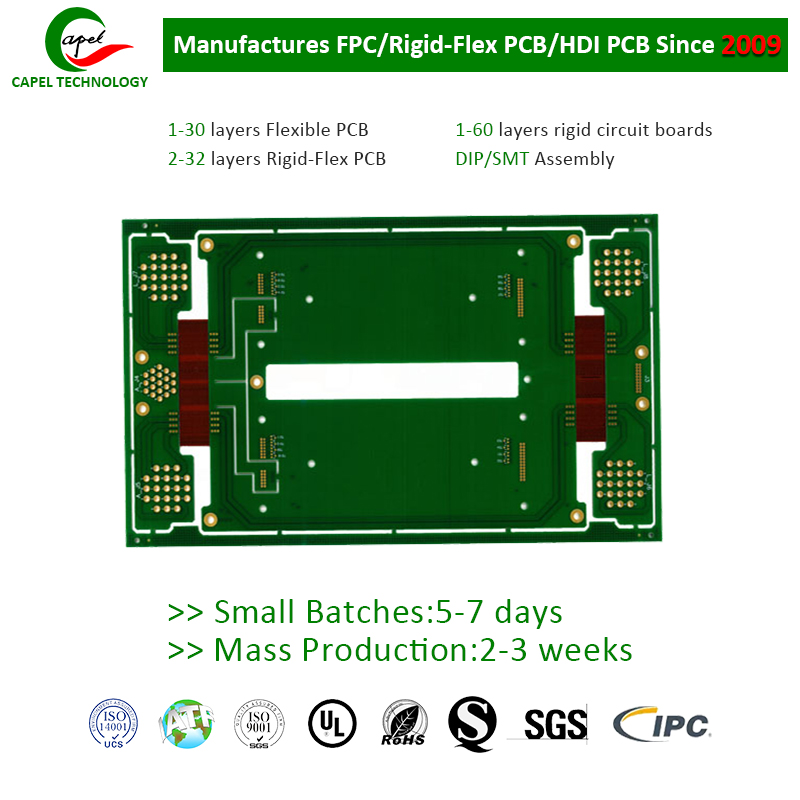

When it comes to the printed circuit board (PCB) world, one of the most interesting types is the rigid-flex PCB. These boards combine the flexibility of flexible PCBs with the rigidity of rigid PCBs and are becoming increasingly popular in various industries. However, one question that arises is: “How long is the lifespan of rigid-flex boards?”

Understanding rigid-flex boards

Before understanding the service life of rigid-flex boards, let’s first understand what they are. Rigid-flex PCBs are circuit boards composed of rigid and flexible areas that enable multifunctional designs. This combination of rigidity and flexibility is achieved through the use of rigid and flexible materials such as FR4 and polyimide. Rigid-flex boards offer several benefits, including reduced assembly time and space requirements, improved reliability, and enhanced durability.

Factors affecting lifespan

When considering the service life of rigid-flex boards, several factors come into play. While these boards are designed to be durable, certain conditions may affect their longevity. Let’s take a closer look at some of the key factors that impact rigid-flex board life:

1. Working conditions: The working conditions to which the rigid-flex board is exposed have a great impact on its service life. Factors such as temperature, humidity and vibration all play a role. Extreme temperatures or excessive humidity can stress the material, possibly leading to delamination or premature failure. Likewise, excessive vibration can cause fatigue in the flex area, leading to cracks or electrical failure.

2. Material Selection: The materials used in the rigid-flexible PCB construction play an important role in determining its service life. High-quality materials with excellent mechanical and thermal properties are essential to ensure long-lasting performance. Choosing materials that have good resistance to heat, chemicals and environmental factors can greatly enhance the durability of the board.

3. Design considerations: The design of rigid-flex boards also has a direct impact on their lifespan. Proper layout, stacking planning and component placement are critical to ensure balanced stress distribution and minimize the risk of failure. Improper layout or poor stackup can create unnecessary stress points that lead to premature board degradation.

4. Manufacturing process: The manufacturing process itself will affect the service life of the rigid-flex board. Precision and quality control during the manufacturing process, including proper lamination and bonding techniques, are critical to avoiding defects that can compromise the integrity of the circuit board. Additionally, proper handling and storage during manufacturing and assembly are also important to prevent any damage that may affect service life.

Conclusion

In summary, the service life of rigid-flex boards is affected by a variety of factors, including operating conditions, material selection, design considerations, and manufacturing processes. By understanding these factors and taking them into consideration during the design and manufacturing stages, the service life of rigid-flex boards can be optimized. Adhering to industry standards and working with an experienced PCB manufacturer can greatly improve the long-lasting performance and reliability of these versatile boards. Therefore, when considering the service life of a rigid-flex board, remember that a well-designed, properly manufactured PCB combined with optimal operating conditions can significantly increase its durability and overall life expectancy.

Post time: Sep-16-2023

Back