Many people will have questions about SMT assembly, such as “what is SMT assembly”? “What are the attributes of SMT assembly?” In the face of all kinds of questions from everyone, Shenzhen Capel Technology Co., Ltd. specially compiled a question and answer material to answer your doubts.

Q1: What is SMIT assembly?

SMT, the abbreviation of surface mount technology, refers to an assembly technology for pasting components (SMC, surface mount components

components or SMD, surface mount device) through the application of a series of SMT assembly equipment to bare PCB (printed circuit

plate).

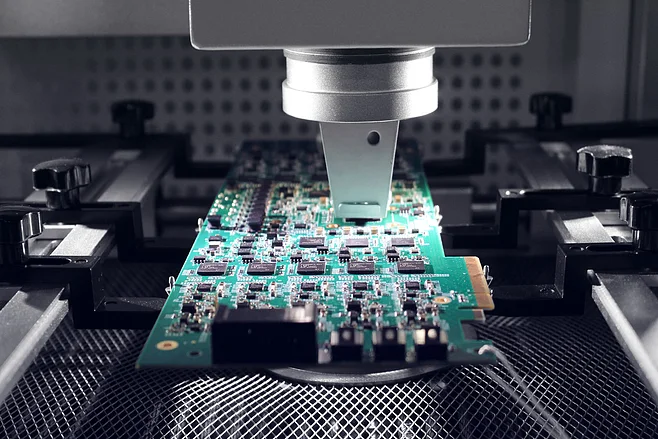

02: What equipment is used in SMT assembly?

Generally speaking, the following equipment is suitable for SMT assembly: solder paste printing machine, placement machine, reflow oven, AOI (automatic

Optical detection) instrument, magnifying glass or microscope, etc.

Q3: What are the properties of SMIT assembly?

Compared with traditional assembly technology, namely THT (Through Hole Technology), SMT assembly results in higher assembly density, smaller

Smaller volume, lighter product weight, higher reliability, higher impact resistance, lower defect rate, higher frequency

rate, reduce EMI (Electromag netic interference) and RF (radio frequency) interference, higher throughput, more self-

Automated access, lower costs, etc.

Q4: What is the difference between SMT assembly and THT assembly?

SMT components differ from THT components in the following ways:

1. Components used for THT components have longer leads than SMT components;

2.THT components need to drill holes on the bare circuit board, while SMT assembly does not, because SMC or SMD are directly mounted

on the PCB;

3. Wave soldering is mainly used in THT assembly, while reflow soldering is mainly used in SMT assembly;

4. SMT assembly can be automated, while THT assembly only depends on manual operation:;

5. The components used for THT components are heavy in weight, high in height and bulky, while SMC helps to reduce more space.

05: Why is it widely used in electronics manufacturing?

First of all, current electronic products have been striving to achieve miniaturization and light weight, and THT assembly is difficult to achieve; secondly

In order to make electronic products functionally integrated, IC (Integrated Circuit) components are largely utilized

used to meet large-scale and high-integrity requirements, which is exactly what SMT assembly can do.

SMT assembly adapts to mass production, automation and cost reduction, all of which meet the needs of the electronics market: Applications

SMT Assembly for Better Promotion of Electronic Technology, Development of Integrated Circuits and Multiple Applications of Semiconductor Materials: SMT Group

The installation complies with international electronic manufacturing standards.

06: In which product areas are SMIT components used?

At present, SMT components have been applied to advanced electronic products, especially computer and telecommunication products.In addition, the SMT group

Components have been applied to products in various fields, including medical, automotive, telecommunications, industrial control, military, aerospace, etc.

Post time: Aug-21-2023

Back