PCB prototype assembly technology plays a vital role in the manufacturing and assembly of circuit boards. These technologies ensure efficient, high-quality and economical production of prototype circuit boards. In this blog post, we will explore some common PCB prototyping assembly techniques. Before going into the details, let’s briefly introduce Capel, a company with 15 years of experience in the circuit board industry, with a professional technical team, advanced circuit board prototype assembly technology, and its own production and assembly factory.

Capel has been a leader in the circuit board industry for over 15 years, dedicated to meeting the diverse needs of its customers. The company has a team of experienced professionals who have gained valuable expertise in the production and assembly of circuit boards. Capel’s advanced circuit board prototyping assembly technology ensures the highest quality standards and efficient manufacturing processes.

Having its own circuit board production and assembly plants gives Capel a competitive advantage. This setup allows the company to better control the production process, ensure timely delivery and maintain excellent quality control. In addition, the company’s expertise in PCB production and assembly enables it to provide customers with comprehensive and cost-effective solutions.

Now that we are familiar with Capel and its capabilities, let’s explore PCB prototyping assembly techniques commonly used in

the industry.

1. Surface mount technology (SMT):

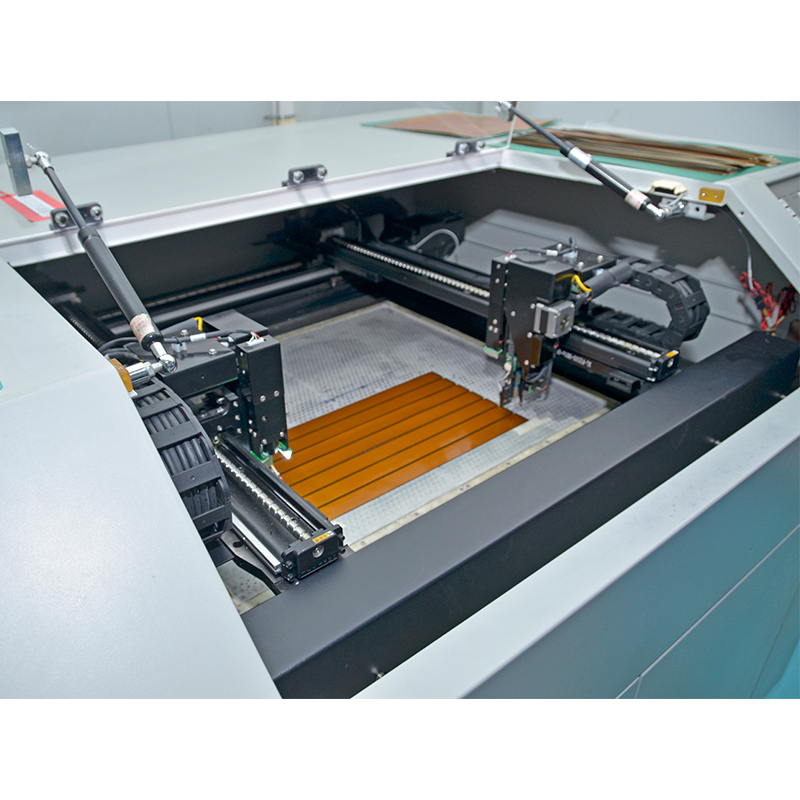

Surface mount technology (SMT) is one of the most widely used PCB assembly technologies. It involves mounting components directly to the PCB surface. SMT offers several advantages, including the ability to accommodate smaller components, higher component density, and improved electrical performance.

2. Through-hole technology (THT):

Through-hole technology (THT) is an older assembly technology that involves mounting components by inserting leads into holes in a PCB and soldering them on the other side. THT is typically used for components that require additional mechanical strength or are too large for SMT.

3. Automatic optical inspection (AOI):

Automated optical inspection (AOI) is a technology used to inspect assembled PCBs for errors or defects. AOI systems use cameras and image recognition algorithms to inspect various aspects of a PCB, such as component placement, solder joints, and polarity. This technology ensures high-quality assembly and reduces the chance of defective products reaching customers.

4. X-ray inspection:

X-ray inspection is a non-destructive inspection technology used to inspect PCBs for hidden features, such as solder joints or underfill materials under components. X-ray inspection helps detect defects such as insufficient solder, cold solder joints, or voids that may not be visible through visual inspection.

5. Rework and repair:

Rework and repair techniques are essential to repair defects or replace faulty components on assembled PCBs. Skilled technicians use specialized tools and equipment to desolder and replace components without causing damage to the PCB. These techniques reduce waste and salvage defective boards, saving time and resources.

6. Selective welding:

Selective soldering is a technique used to solder through-hole components on a PCB without affecting the soldered surface mount components. It provides greater accuracy and reduces the chance of damaging nearby components.

7. Online Test (ICT):

In-circuit testing (ICT) uses specialized test equipment to check the functionality of circuit components on a PCB. It helps detect faulty components, open or short circuits or incorrect component values. ICT provides valuable feedback to improve the design and assembly process.

These are just some of the common PCB prototyping assembly techniques used by companies like Capel. The continuous development of technology allows manufacturers to explore new methods and innovate in the field of circuit board assembly.

Capel’s extensive experience and technical expertise in the circuit board industry, coupled with its advanced PCB prototype assembly technology, makes it a trusted partner for its customers. The company’s commitment to providing efficient, high-quality and economical prototype circuit board manufacturing and assembly services sets it apart in the market.

In summary, understanding common PCB prototyping assembly techniques is critical for both manufacturers and customers. Companies like Capel leverage their expertise, experience, and advanced technology to provide superior circuit board manufacturing and assembly solutions. By choosing a reliable partner like Capel, customers benefit from efficient processes, superior quality control and cost-effective solutions.

Post time: Oct-19-2023

Back