Introduce:

In this blog, we’ll explore the versatility of rigid-flex boards and their ability to handle high-speed signals.

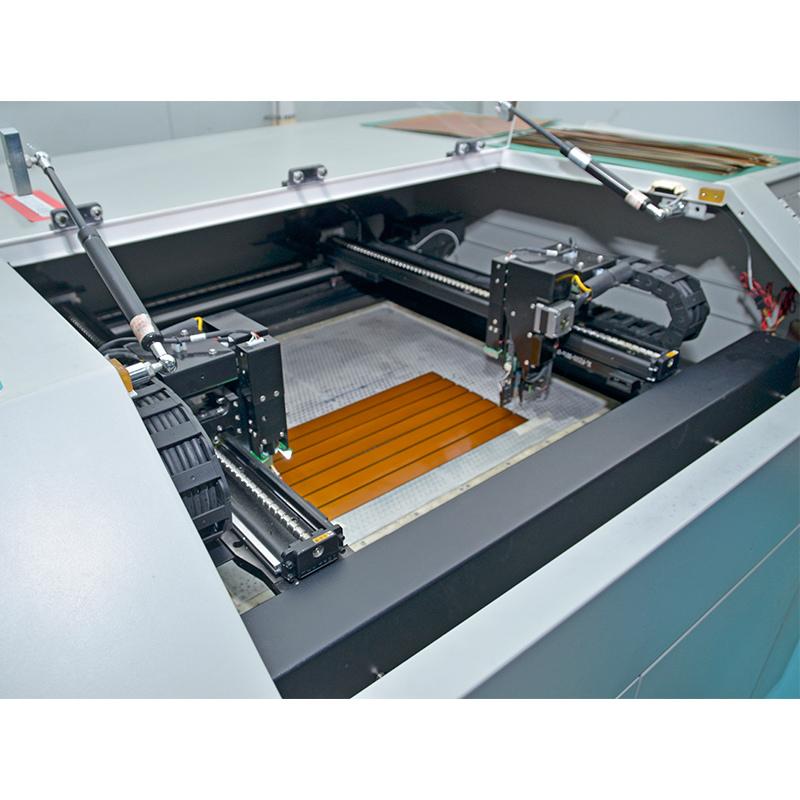

In today’s technologically advanced world, where electronic devices are becoming smaller, lighter, and more complex, the demand for flexible and high-speed printed circuit boards (PCBs) continues to increase. Rigid-flex boards have emerged as a practical solution that combines the advantages of rigid and flexible PCBs, making them ideal for accommodating high-speed signals.

Part 1: Understanding Rigid-Flex Boards

Rigid-flex is a hybrid type of PCB that combines layers of rigid and flexible materials. These boards consist of flexible circuits interconnected with rigid sections, providing both mechanical stability and flexibility. The combination of rigid and flexible sections allows the board to bend or fold as needed without affecting its performance.

Section 2: High Speed Signal Transmission

High-speed signals are rapidly changing electrical signals that exceed a specific frequency threshold. These signals require special consideration during PCB design and layout to avoid signal integrity issues such as crosstalk, impedance mismatch, and signal distortion. Rigid-flex boards have unique advantages in processing high-speed signals due to their flexibility and shorter signal transmission distance.

Section 3: Rigid-flexible design considerations for high-speed signals

3.1 Controlled impedance:

Maintaining controlled impedance is critical to high-speed signal integrity. Rigid-flex boards allow for better impedance control because the flex portions can be designed with precise trace geometries and widths. This allows for minimal routing changes for signal traces, ensuring consistent impedance throughout the board.

3.2 Signal routing and layer stacking:

Proper signal routing and layer stacking are critical to minimizing signal crosstalk and achieving optimal performance. Rigid-flex boards allow for flexible placement of high-speed signal traces, thereby shortening transmission distances and reducing unwanted signal interactions. Additionally, the ability to stack multiple layers within a compact form factor enables effective separation of power and ground planes, further enhancing signal integrity.

3.3 EMI and crosstalk mitigation:

Electromagnetic interference (EMI) and crosstalk are common challenges when handling high-speed signals. The advantage of rigid-flex boards is the combination of shielding and proper ground plane configuration, which reduces the risk of EMI and crosstalk. This ensures that the signal remains stable and free of interference, improving overall system performance.

Section 4: Advantages and applications of high-speed signal rigid-flex boards

4.1 Space-saving design:

Rigid-flex panels have significant advantages in applications where space is limited. Their ability to bend and adapt to the available space allows optimal use of space, making them ideal for compact electronic devices.

4.2 Reliability and Durability:

Rigid-flex boards offer greater reliability than traditional rigid PCBs due to reduced interconnect count and potential failure points. Additionally, the absence of connectors and ribbon cables minimizes the risk of signal degradation and ensures long-term durability.

4.3 Application:

Rigid-flex boards are widely used in various industries, including aerospace, medical devices, consumer electronics and automotive. They are the first choice for applications where size, weight and reliability are critical and where high-speed signal transmission is required.

In conclusion:

As the demand for high-speed signal transmission continues to grow, rigid-flex boards have become a versatile solution. Their unique combination of flexibility, space-saving design and signal integrity features make them ideal for accommodating high-speed signals. By combining controlled impedance, efficient signal routing and appropriate EMI/crosstalk mitigation techniques, rigid-flex boards ensure reliable and optimal performance in a variety of applications.

Post time: Oct-07-2023

Back