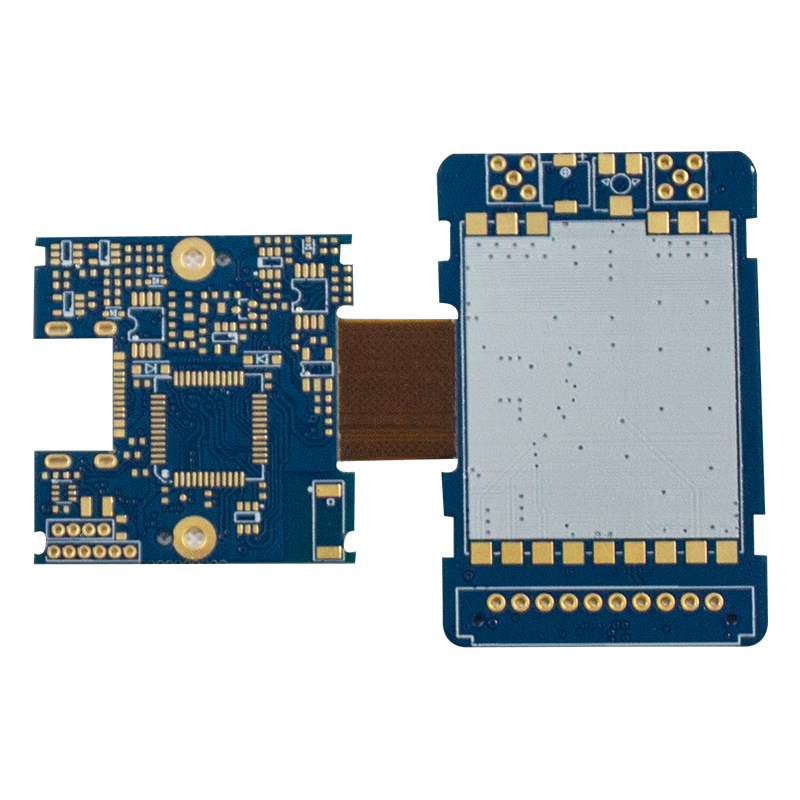

In the world of printed circuit boards (PCBs), the choice of materials and manufacturing processes can greatly impact the quality and performance of electronic devices. One such variant is the thick gold PCB, which offers unique advantages over standard PCBs. Here we aims to provide a comprehensive understanding of thick gold PCB, explaining its composition, advantages, and differences from traditional PCBs

1.Understanding Thick Gold PCB

Thick gold PCB is a special type of printed circuit board that has a significantly thicker gold layer on its surface. They are composed of multiple layers of copper and dielectric materials with a gold layer added on top. These PCBs are manufactured through an electroplating process that ensures the gold layer is even and firmly bonded.Unlike standard PCBs, thick gold PCBs have a significantly thicker gold plating layer on the final surface finish. Gold thickness on a standard PCB is typically about 1-2 micro inches or 0.025-0.05 microns. In comparison, thick gold PCBs typically have a gold layer thickness of 30-120 micro inches or 0.75-3 microns.

2.Advantages of thick gold PCB

Thick gold PCBs offer many advantages over standard options, including enhanced durability, improved conductivity and superior performance.

Durability:

One of the main advantages of thick gold PCBs is their exceptional durability. These boards are specifically designed to withstand harsh environments, making them ideal for applications that are frequently exposed to extreme temperatures or harsh conditions. The thickness of the gold plating provides a layer of protection against corrosion, oxidation and other forms of damage, ensuring a longer PCB life.

Enhance electrical conductivity:

Thick gold PCBs have excellent electrical conductivity, making them the first choice for applications requiring efficient signal transmission. The increased thickness of gold plating reduces resistance and enhances electrical performance, ensuring seamless signal transmission across the board. This is particularly important for industries such as telecommunications, aerospace and medical devices, where accurate and reliable data transmission is critical.

Improve solderability:

Another advantage of thick gold PCBs is their improved solderability. Increased gold plating thickness allows for better solder flow and wetting, reducing the likelihood of solder reflow issues during manufacturing. This ensures strong and reliable solder joints, eliminating potential defects and improving overall product quality.

Contact life:

Electrical contacts on thick gold PCBs last longer due to the increased gold plating thickness. This enhances contact reliability and reduces the risk of signal degradation or intermittent connectivity over time. Therefore, these PCBs are widely used in applications with high insertion/extraction cycles, such as card connectors or memory modules, which require long-lasting contact performance.

Improve wear resistance:

Thick gold PCBs perform well in applications that require repeated wear and tear. The increased thickness of the gold plating provides a protective barrier that helps withstand the rubbing and rubbing effects of repeated use. This makes them ideal for connectors, touchpads, buttons and other components that are prone to constant physical contact, ensuring their longevity and consistent performance.

Reduce signal loss:

Signal loss is a common problem in high frequency applications. However, thick gold PCBs offer a viable solution that can minimize signal loss due to their enhanced conductivity. These PCBs feature low resistance to ensure optimal signal integrity, minimize data transmission losses and maximize system efficiency. Therefore, they are widely used in industries such as telecommunications, wireless equipment, and high-frequency equipment.

3.The importance of increasing gold plating thickness for thick gold PCBs:

The increased thickness of gold plating in thick gold PCBs serves several important purposes. First, it provides additional protection against oxidation and corrosion, ensuring long-term reliability and stability even in harsh environments. The thick gold plating acts as a barrier, preventing any chemical reactions between the underlying copper traces and the outside atmosphere, especially if exposed to moisture, humidity, or industrial contaminants.

Secondly, the thicker gold layer enhances the overall conductivity and signal transmission capabilities of the PCB. Gold is an excellent conductor of electricity, even better than the copper commonly used for conductive traces in standard PCBs. By increasing the gold content on the surface, thick gold PCBs can achieve lower resistivity, minimizing signal loss and ensuring better performance, especially in high-frequency applications or those involving low-level signals.

In addition, thicker gold layers provide better solderability and a stronger component mounting surface. Gold has excellent solderability, allowing for reliable solder joints during assembly. This aspect is critical because if the solder joints are weak or irregular, it can cause intermittent or complete circuit failure. Increased gold thickness also improves mechanical durability, making thick gold PCBs less susceptible to wear and tear and more resistant to mechanical stress and vibration.

It is worth noting that the increased thickness of the gold layer in thick gold PCBs also brings higher costs compared to standard PCBs. The extensive gold plating process requires additional time, resources and expertise, resulting in increased manufacturing expenses. However, for applications requiring superior quality, reliability and longevity, the investment in thick gold PCBs often outweighs the potential risks and costs associated with using standard PCBs.

4.The difference between thick gold PCB and standard PCB:

Standard PCBs are usually made of epoxy material with a copper layer on one or both sides of the board. These copper layers are etched during the manufacturing process to create the necessary circuitry. The thickness of the copper layer can vary depending on the application, but is typically in the 1-4 oz range.

Thick gold PCB, as the name suggests, has a thicker gold plating layer compared to standard PCB. Standard PCBs typically have a gold plating thickness of 20-30 micro inches (0.5-0.75 microns), while thick gold PCBs have a gold plating thickness of 50-100 micro inches (1.25-2.5 microns).

The main differences between thick gold PCBs and standard PCBs are gold layer thickness, manufacturing complexity, cost, application areas, and limited applicability to high-temperature environments.

Gold layer thickness:

The main difference between thick gold PCB and standard PCB is the thickness of the gold layer. Thick gold PCB has a thicker gold plating layer than standard PCB. This extra thickness helps improve the PCB’s durability and electrical performance. The thick gold layer provides a protective coating that enhances the PCB’s resistance to corrosion, oxidation and wear. This makes the PCB more resilient in harsh environments, ensuring long-term reliable operation. Thicker gold plating also allows for better electrical conductivity, allowing for efficient signal transmission. This is particularly advantageous in applications requiring high-frequency or high-speed signal transmission, such as telecommunications, medical equipment, and aerospace systems.

Cost:

Compared with standard PCB, the production cost of thick gold PCB is usually higher. This higher cost results from the plating process requiring additional gold material to achieve the required thickness. However, the greater reliability and performance of thick gold PCBs justify the additional cost, especially in applications where demanding requirements must be met.

Application areas:

Standard PCBs are widely used in various industries, including consumer electronics, automotive systems and industrial equipment. They are suitable for applications where high reliability is not a top priority. Thick gold PCBs, on the other hand, are mainly used in professional fields that require superior reliability and performance. Examples of these application areas include the aerospace industry, medical equipment, military equipment, and telecommunications systems. In these areas, critical functions rely on reliable and high-quality electronic components, so thick gold PCBs are the first choice.

Manufacturing Complexity:

Compared with standard PCBs, the manufacturing process of thick gold PCBs is more complex and time-consuming. The electroplating process must be carefully controlled to achieve the desired gold layer thickness. This increases the complexity and time required of the production process. Precise control of the plating process is critical because variations in gold layer thickness can affect PCB performance and reliability. This meticulous manufacturing process contributes to the superior quality and functionality of thick gold PCBs.

Limited suitability for high temperature environments:

While thick gold PCBs perform well in most environments, they may not be the most suitable choice for high temperature applications. Under extreme high temperature conditions, thick gold layers can degrade or delaminate, affecting the overall performance of the PCB.

In this case, alternative surface treatments such as immersion tin (ISn) or immersion silver (IAg) may be preferred. These treatments provide adequate protection against the effects of high temperatures without affecting the functionality of the PCB.

The choice of PCB materials can significantly impact the quality and performance of electronic devices. Thick gold PCBs provide unique advantages such as enhanced durability, improved solderability, excellent electrical conductivity, superior contact reliability, and extended shelf life. Their benefits justify the higher production cost and make them particularly suitable for specialized industries that prioritize reliability, such as aerospace, medical devices, military equipment, and telecommunications systems. Understanding the composition, advantages, and differences between thick gold PCBs and standard PCBs is crucial for engineers, designers, and manufacturers seeking to optimize the performance and longevity of their electronic devices. By leveraging the unique qualities of thick gold PCBs, they can ensure reliable and high-quality products for their customers.

Post time: Sep-13-2023

Back