Discover the world of ultra-thin flexible PCBs and their diverse applications with Capel, a leading manufacturer with 16 years of expertise. Learn about the importance of flexible PCB thickness, Capel’s advanced technology, successful case studies and more about flexible PCB design, prototyping The advantage of working with a pioneer in manufacturing.

Launch of ultra-thin flexible PCB: a technological marvel

A. Brief Overview of Flexible PCB

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry by providing lightweight, compact and versatile solutions for connecting electronic components. Their flexibility and adaptability make them ideal for applications where traditional rigid PCBs are not suitable.

B. Understand the importance of flexible PCB thickness

The thickness of a flexible PCB plays a vital role in determining its performance, durability and suitability for a specific application. As technology advances, the demand for thinner and more flexible PCBs continues to increase, driving the need for manufacturers to develop ultra-thin solutions.

C. Introduction to Capel’s services and expertise in flexible PCB manufacturing

With 16 years of experience in flex circuit prototyping and manufacturing, Capel has become a leading manufacturer of flexible PCBs. Our expertise in producing ultra-thin flexible PCBs (minimum thickness 0.025 mm) sets us apart in the industry. Our advanced process capabilities, strong R&D capabilities and commitment to technological innovation make us the partner of choice for complex electronic applications.

The Science of Flexible PCB Thickness: Factors and Considerations

A. What is the standard thickness of flexible PCB?

The standard thickness of flexible PCB is usually between 0.05mm and 0.5mm, depending on the specific requirements of the application. However, advances in manufacturing processes have made it possible to produce ultra-thin flexible PCBs with thicknesses as low as 0.025mm.

B. Factors affecting the thickness of flexible PCB

Several factors affect the thickness of a flexible PCB, including the type of substrate material, the number of copper layers, and specific design requirements. Understanding these factors is critical to achieving the desired level of flexibility and performance in the final product.

C. Capel’s expertise in producing ultra-thin flexible PCBs

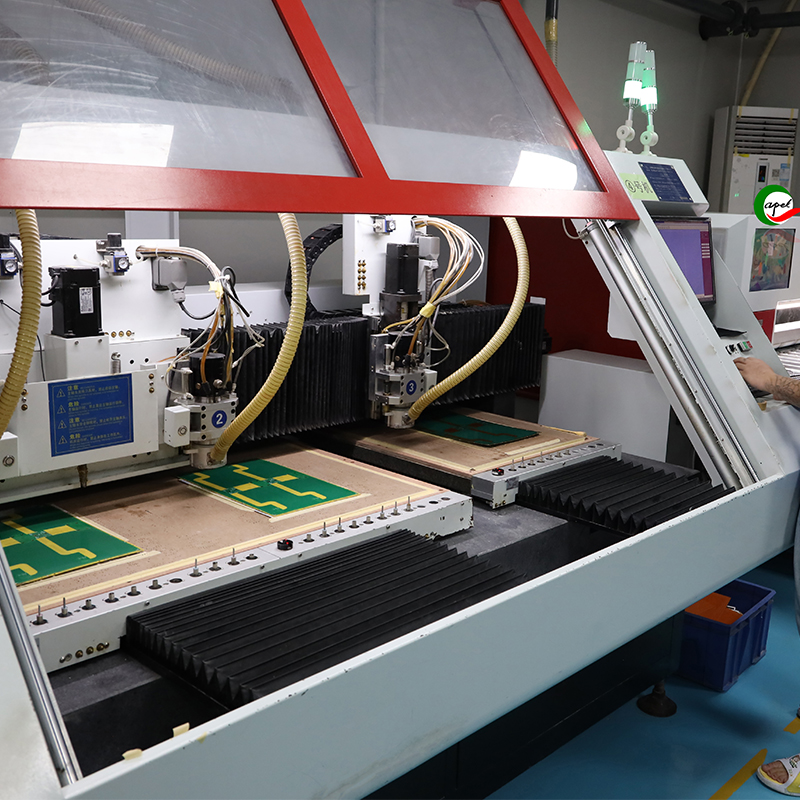

At Capel, we invest heavily in research and development to perfect the manufacturing process of ultra-thin flexible PCBs. Our state-of-the-art facilities and advanced technology enable us to achieve unparalleled precision and consistency in producing ultra-thin PCBs to meet our customers’ most demanding specifications.

Navigating the world of rigid-flex PCBs: versatility and durability

A. Introduction to rigid-flex board

Rigid-Flex PCBs combine the advantages of rigid and flexible PCBs to provide versatile solutions for complex electronic applications. The ability to bend and fold without affecting performance makes rigid-flex PCBs ideal for space-constrained and high-reliability applications.

B. Comparison of thickness between flexible circuit board and flex-rigid board

Traditional flexible PCBs offer excellent flexibility, while rigid-flex PCBs provide additional structural support and durability. Rigid-flex boards are typically available in thicknesses from 0.1 mm to 0.5 mm, with ultra-thin options available for applications requiring maximum flexibility and space savings.

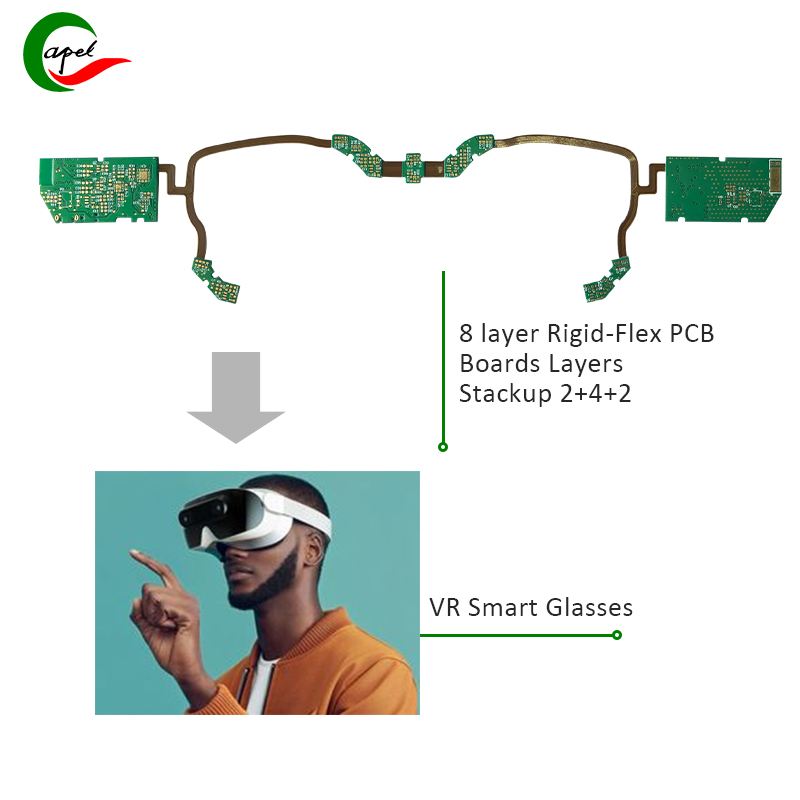

C. Capel specializes in manufacturing ultra-thin rigid-flex boards

Capel’s advanced technology and expertise extend to the production of ultra-thin rigid-flex PCBs with a minimum thickness of 0.4 mm. Our ability to deliver ultra-thin rigid-flex solutions makes us a trusted partner for customers with stringent space and performance requirements.

Applications of ultra-thin flexible PCBs: Industry insights and success stories

A. Overview of industries and applications benefiting from ultra-thin flexible PCBs

The demand for ultra-thin flexible PCBs spans various industries, including consumer electronics, medical devices, aerospace, automotive and wearable technology. The ability to integrate complex electronics into compact, lightweight designs opens up new possibilities for innovative product development.

B. Case studies and success stories using the thinnest flexible PCB in smart wearable industry.

Capel has a proven track record of providing custom ultra-thin flexible PCB solutions for a variety of applications. Our success stories include working with leading companies to overcome industry-specific challenges such as miniaturization, high-density interconnects and reliability in harsh environments.

Capel’s thinnest rigid-flex board (0.4mm) has been successfully used in the development of smart wearables, demonstrating its technological innovation and performance improvement. A leading smart wearable company sought to create a wearable device that required a highly flexible, ultra-thin PCB to fit seamlessly into clothing without compromising performance. Capel’s custom ultra-thin flexible PCB solution proved to be ideal for this application.

Technical analysis of the case shows that Capel’s thinnest rigid-flex PCB enables smart wearable devices to achieve stylish and comfortable designs while maintaining high-density interconnection and reliability under various environmental conditions. The ultra-thin nature of PCBs allows them to be seamlessly integrated into smart wearable fabrics, providing flexibility and durability without sacrificing performance.

Additionally, the use of Capel’s thinnest rigid-flex PCB facilitates miniaturization, making smart wearable devices lightweight and unobtrusive while still delivering powerful functionality. The innovative design and performance improvements brought by Capel’s ultra-thin flexible PCB solutions have made this smart wearable company a leader in the wearable technology market.

Capel’s ultra-thin rigid flex PCB provides excellent bending and bending performance, allowing wearable smart products to better adapt to human body movements and activities while maintaining stable electrical connections, thereby enhancing the product comfort and wearability.

The design of ultra-thin rigid flex PCB allows high-density interconnection in a limited space, which provides more possibilities for functional enhancement and component integration of wearable smart products, thus improving the product performance and functional diversity.

Capel’s ultra-thin rigid flex PCB has undergone rigorous reliability testing and can maintain stable performance in harsh environments, such as high temperature, humidity and mechanical stress, which provides a wider range of usage scenarios for wearable smart products. possibilities, thereby improving product reliability and durability.

This case demonstrates how Capel’s thinnest rigid-flex PCB enables technological innovation and performance improvements in the smart wearable industry, demonstrating the company’s expertise in providing customized ultra-thin flex PCB solutions for cutting-edge applications .

C. Capel’s role in providing customized ultra-thin flexible PCB solutions

Our commitment to innovation and excellence is demonstrated by our ability to customize ultra-thin flexible PCB solutions to meet each customer’s unique requirements. With our proven technology, strength, professionalism and advanced process capabilities, we enable our customers to bring their cutting-edge products to market with confidence.

Ultra-Thin Flexible PCBs Prototype Process

In conclusion-Capel’s technical strength: leading ultra-thin PCB solutions

A. Review the importance of understanding flexible PCB thickness

The thickness of a flexible PCB is a key factor that directly affects its performance and suitability for a specific application. As the demand for thinner, more flexible PCBs continues to grow, manufacturers must prioritize and solve the challenges associated with ultra-thin PCB production.

B. Highlight Capel’s expertise in producing the thinnest flex and rigid-flex PCBs

Capel is committed to pushing the boundaries of flexible PCB technology, as evidenced by our ability to produce the thinnest flexible and rigid-flex PCBs on the market. Our commitment to excellence and continuous improvement makes us a trusted partner for customers looking for innovative and reliable PCB solutions.

C. A call to action for readers to take action to explore Capel’s services for their flexible PCB needs

We invite readers to explore Capel’s comprehensive range of flexible PCB manufacturing services, including ultra-thin flex and rigid-flex solutions. Our team of experts is ready to work with you to bring your most ambitious electronic designs to reality with the highest level of quality and performance.

Overall, the exploration of ultra-thin flexible PCBs and their applications highlights the key role Capel plays in driving technological innovation and solving industry-specific challenges for its customers. Our successful case studies and advanced technologies in flexible PCB design, prototyping and manufacturing demonstrate our unwavering commitment to excellence and our ability to deliver cutting-edge solutions that enable our customers to succeed in their respective markets.

Post time: Apr-07-2024

Back