The ultimate guide to discovering 2-layer flexible PCBs in new energy vehicles, with a focus on electric vehicle battery applications. Get an in-depth look at the technical specifications, case studies, and critical role these PCBs play in improving vehicle performance and safety

1. The significance of 2-layer flexible PCB in new energy vehicles

The rapid development of new energy vehicles has brought major changes to the automobile industry. As demand for electric vehicles continues to grow, the need for reliable, efficient electronic components is more important than ever. One of the components that plays a key role in the performance and safety of new energy vehicles is the 2-layer flexible PCB. In this ultimate guide, we’ll dive into the importance of 2-layer flexible PCBs in new energy vehicles, with a special focus on their use in electric vehicle batteries.

2. Understand 2-Layer Flexible PCB: Features and Benefits

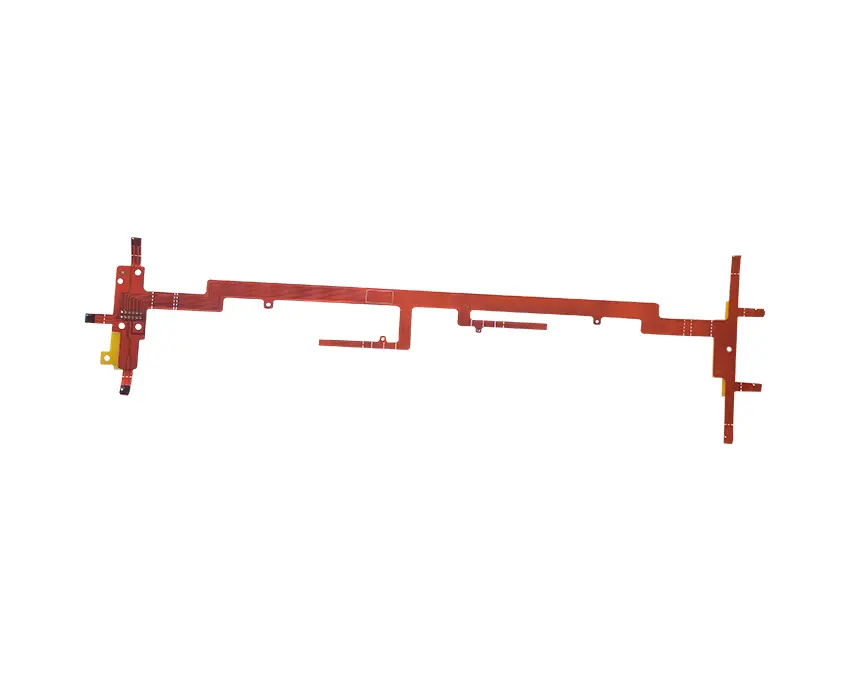

2-layer flexible PCBs, also known as flexible printed circuit boards, are an important component in the design and manufacturing of electronic devices, especially in the automotive industry. These PCBs feature the ability to bend and bend, making them ideal for applications where space and weight are critical. Key features and benefits of 2-layer flexible PCBs include lightweight, high flexibility and excellent thermal performance. In the context of new energy vehicles, 2-layer flexible PCB plays a vital role in battery protection circuit boards to ensure the safe and efficient operation of electric vehicle batteries.

3. Case Study: 2-Layer Flexible PCB in Electric Vehicle Batteries

When it comes to electric vehicle batteries, 2-layer flexible PCBs help ensure reliable and safe operation of the battery management system. These PCBs typically consist of polyimide (PI) as the base material, copper for the conductive traces, and an adhesive to hold the layers together. Technical specifications for 2-layer flexible PCBs for electric vehicle batteries include specific line widths and spacings, board thickness, minimum apertures, surface finishes and impedance tolerances. These specifications are critical to meeting the stringent requirements for high performance and safety of new energy vehicles.

4. The key role of 2-layer flexible PCB in new energy vehicles

The importance of 2-layer flexible PCB in new energy vehicles cannot be overstated. These PCBs are critical to improving the overall performance and safety of electric vehicles, especially in terms of battery management and protection. The specific application of 2-layer flexible PCBs in electric vehicle batteries directly affects the efficiency and reliability of the vehicle, making it a key component in the transition to sustainable transportation solutions.

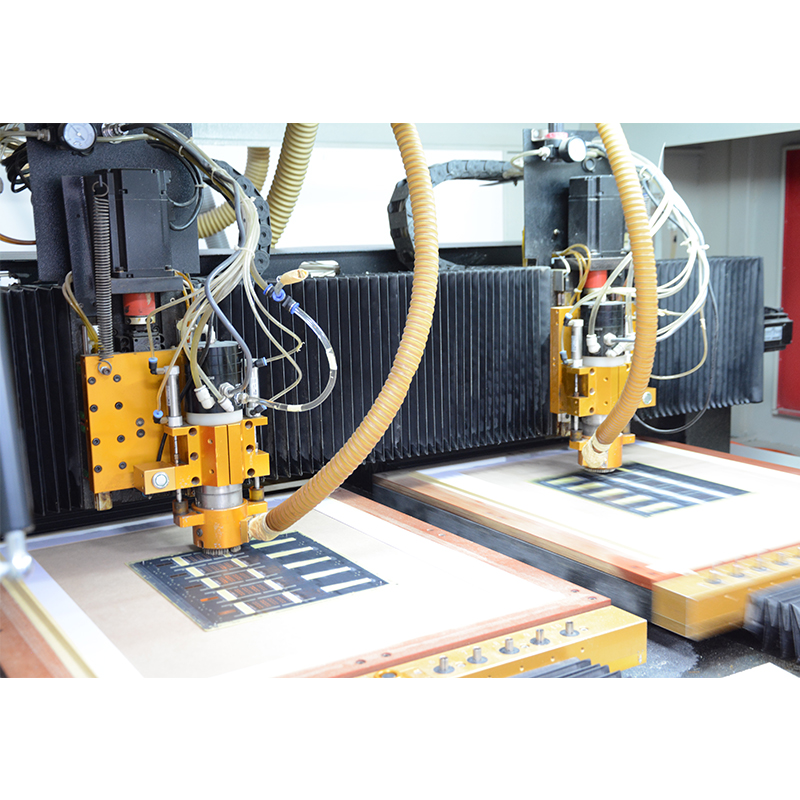

5. Company Expertise: Capel’s 16 Years of Flexible PCB Manufacturing Excellence

For 16 years, Capel has been at the forefront of high-quality 2-layer flexible PCB manufacturing, focusing on meeting the demanding requirements of new energy vehicles. Our expertise and experience in this field enables us to provide cutting-edge solutions that meet the ever-changing needs of the automotive industry. With state-of-the-art manufacturing capabilities, Capel has the capability to produce 2-layer flexible PCBs that meet the strict technical specifications and performance standards of new energy vehicles.

2 Layer Flexible PCB Manufacturing Process for New Energy Vehicle Battery

6. Conclusion: The future of 2-layer flexible PCB in new energy vehicles

To sum up, the significance of 2-layer flexible PCB in new energy vehicles cannot be ignored. As electric vehicles continue to gain traction in the market, the role of 2-layer flexible PCBs in ensuring the performance and safety of these vehicles becomes increasingly important. The case study presented highlights the specific application of 2-layer flexible PCBs in electric vehicle batteries and its profound impact on the automotive industry. Looking to the future, 2-layer flexible PCBs in new energy vehicles will further develop and promote innovation and sustainable development in the automotive industry.

Post time: Mar-11-2024

Back