Significant advances have been made in the field of printed circuit boards (PCBs) over the years to meet the growing demand for compact, lightweight and multifunctional electronic devices. One of the breakthroughs in PCB technology is the emergence of rigid-flex PCB. Combining the best qualities of rigid and flexible PCBs, these innovative circuit boards have revolutionized industries ranging from consumer electronics to healthcare. In this blog, we will explore the evolution, benefits and applications of rigid-flex boards, showing their importance in modern electronic design.

1. Understand rigid-flex PCB:

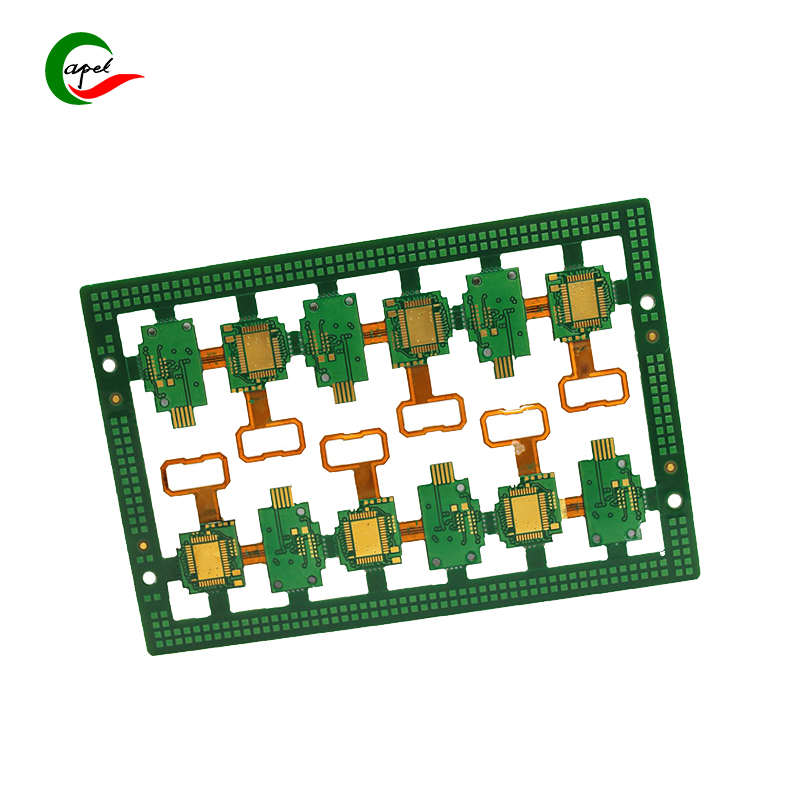

Rigid-flexible PCB, as the name suggests, is the perfect combination of rigid and flexible PCB. These unique boards integrate rigid and flexible substrates to enable complex three-dimensional (3D) designs. The rigid part provides stability and structural support, while the flexible part allows bending and folding.

2. The evolution of rigid-flex PCB:

The development of rigid-flex PCB technology can be attributed to the growing demand for compact, lightweight electronic devices. Initially, PCBs were designed using only rigid substrates. However, advances in materials and fabrication techniques have led to the introduction of flexible substrates. The fusion of these two types of PCBs paved the way for the birth of rigid-flex PCBs.

In the early stages, rigid-flex boards were mainly used in aerospace and military applications, where the need for lightweight and durable circuits was critical. However, with the development of technology, rigid-flex PCB has entered a wide range of industries. Today, these boards are common in consumer electronics, medical devices, automotive systems, and more.

3. Advantages of rigid-flexible boards :

Rigid-flex PCBs offer several distinct advantages over traditional rigid or flex PCBs. Let’s dig into the most notable ones:

a) Size and weight reduction: The ability to bend, fold, and adapt to irregular shapes facilitates compact and lightweight designs. This is especially beneficial for modern electronics where space optimization is critical.

b) Enhanced reliability: Rigid-flex PCBs eliminate the need for multiple interconnects and connectors, reducing the risk of points of failure. This increases reliability, improves signal integrity and reduces maintenance issues.

c) Improved thermal management: The combination of rigid and flexible materials can effectively dissipate heat and prevent overheating of critical electronic components. This advantage is especially valuable in high-performance applications.

d) Increased design flexibility: Rigid-flex PCBs offer unparalleled design freedom, enabling engineers to create complex and space-saving layouts. This flexibility enables the integration of additional functions such as built-in antennas, sensors and interconnects for advanced functions.

4. Application of rigid-flexible board :

Rigid-flex PCBs are widely used in various industries due to their unique qualities. Some notable applications include:

a) Consumer Electronics: Rigid-flex PCBs have become an integral part of modern devices such as smartphones, tablets, wearables and gaming consoles. These boards enable seamless integration of multiple components in a compact form factor.

b) Medical devices: Rigid-flex boards are widely used in medical applications, from implantable devices to diagnostic devices. Their flexibility combined with biocompatible materials enables comfortable and reliable medical implants and wearable medical devices.

c) Automotive systems: Rigid-flex plays a key role as the automotive industry moves toward electric vehicles and autonomous driving. From engine control units to navigation systems, these boards enable efficient data transfer, space optimization and increased vehicle reliability.

d) Aerospace and Defense: Rigid-flex PCBs have been used in aerospace and defense applications for decades. These boards provide lightweight and high-reliability solutions for satellite systems, military aircraft, and communication systems.

e) Industrial automation: Rigid-flex boards are ideal for industrial automation equipment and control systems. They are robust, vibration-resistant and capable of withstanding harsh environmental conditions.

Rigid-flex PCBs have truly changed the world of electronic circuits, offering unrivaled design freedom, reliability and space-saving opportunities. As the technology continues to develop, we can expect more advancements in this area, further expanding the range of applications for rigid-flex boards. Capable of accommodating complex space requirements while ensuring superior performance, these motherboards will revolutionize countless industries and shape the future of electronic equipment.

Post time: Aug-21-2023

Back