In the context of the rapid development of the new energy field, the demand for advanced industrial control PCB boards has surged, which has brought both huge opportunities and challenges. As an experienced rigid-flex PCB engineer with over 15 years of experience in the industrial control PCB manufacturing industry, I have the privilege of leading the development and implementation of cutting-edge design technologies to meet the unique needs of the new energy sector. In this article, we will explore the innovative solutions that enable us to exceed industry standards and deliver optimal performance to our clients, backed by successful case studies that highlight the effectiveness of our approach.

Challenges in the field of new energy

The new energy sector covers a wide range of technologies and applications, including renewable energy systems, energy storage devices, and electric vehicle infrastructure, each with its complexities and requirements. To support the seamless and efficient operation of these systems, industrial control PCB boards must exhibit exceptional durability, reliability, and functionality while overcoming size, weight, and power consumption limitations. Additionally, the harsh environmental conditions these systems often face require rugged designs that can withstand extreme temperatures, vibration, and moisture without compromising performance.

Faced with these challenges, the successful development and deployment of industrial control PCB fabrication depends on the utilization of the latest design technology and a deep understanding of the specific requirements of the new energy field. As the following case studies demonstrate, the combination of expertise and innovation is critical to our ability to deliver unparalleled solutions to our clients.

Case study 1: Improving the efficiency of renewable energy systems

One of our customers, a leading solar solutions provider, approached us for help with an urgent need to optimize the performance of his solar inverter. These key components convert direct current (DC) generated by solar panels into alternating current (AC) used in homes and businesses. As the heart of a solar system, the performance and reliability of the inverter are critical to the overall efficiency of solar power generation.

Recognizing the importance of this challenge, our team pioneered the development of a custom rigid-flex PCB design that not only meets the stringent requirements for power handling and thermal management but also provides enhanced durability and extended service life. Utilizing advanced materials and design techniques, we designed a solution that can be seamlessly integrated into a compact solar inverter while delivering superior performance in terms of power conversion efficiency and operational stability. By simplifying the internal architecture and optimizing signal routing, we achieve tangible improvements in overall solar system power generation, exceeding customer expectations and contributing to the widespread adoption of renewable energy technologies.

Case study 2: Implementing high power density energy storage systems

In another compelling case, a leading energy storage technology company sought our expertise in developing industrial control PCB boards for its advanced lithium-ion battery management system. Focused on maximizing energy density and operational safety, our customers presented us with a complex set of requirements, including high-voltage isolation, precise thermal management, and robust fault detection mechanisms. Additionally, the growing demand for compact, lightweight energy storage solutions requires a design approach that can accommodate rising power densities without compromising reliability or safety.

Leveraging our extensive experience in high-performance PCB design, we conduct a thorough analysis of our customer’s specifications and industry regulations, laying the foundation for innovative design solutions tailored to the unique needs of energy storage applications. By leveraging the latest advances in multi-layer rigid-flex PCB technology, we designed a modular, scalable architecture that not only facilitates seamless integration within the battery management system but also without sacrificing safety or reliability The power density is greatly improved. Through sophisticated impedance control, thermal vias, and meticulous layout optimization, we not only minimized the PCB board footprint but also enhanced its ability to handle the stringent requirements of high-rate charge and discharge cycles.

The successful deployment of our advanced PCB boards in customers’ energy storage systems has significantly increased overall energy density and system efficiency, allowing them to provide customers with more compact and powerful solutions. Additionally, our collaborative approach to addressing regulatory compliance and safety issues underscores our commitment to providing comprehensive solutions that are aligned with the evolving landscape of the new energy industry.

Case study 3: Power electronics for electric vehicle charging infrastructure

In the electric vehicle sector, the proliferation of electric vehicles is driving the need for robust and efficient electric vehicle supply equipment (EVSE) and charging infrastructure. The prowess of our technology was put to the test when a prominent manufacturer of electric vehicle charging stations sought to improve the performance and reliability of its fast-charging solutions while mitigating challenges associated with high power distribution and thermal management. As the popularity of electric vehicles continues to soar, the need for fast, safe, and scalable charging infrastructure becomes increasingly apparent, highlighting the critical role of industrial control PCB boards in these systems.

Driven by the philosophy of driving innovation in the electric vehicle ecosystem, our team designs high-voltage, high-current PCB solutions that orchestrate the complex interplay of power electronics, thermal dissipation, and communication interfaces within the charging infrastructure. By leveraging our expertise in high-voltage isolation, impedance matching, and reliable interconnects, we designed an optimized rigid-flex PCB architecture that enhances the charging station’s power handling capabilities and exhibits excellent resistance to environmental stresses and operational differentiation capabilities.

Our advanced PCB boards are successfully integrated into electric vehicle charging infrastructure, significantly improving charging efficiency and system reliability, and reducing the overall charging station footprint. This in turn facilitates the seamless expansion of electric vehicle charging networks, giving drivers convenient access to fast, reliable charging solutions. Our commitment to pushing the boundaries of double-sided industrial control PCB board technology in electric vehicles reflects our unwavering commitment to driving positive change in the new energy field.

Keep moving forward with innovation and reliability

These compelling case studies demonstrate that the latest design technologies for industrial control PCB manufacturing play a key role in solving the multi-faceted challenges in the new energy sector. By leveraging domain expertise, research-driven innovation, and an unwavering commitment to delivering superior performance, we not only meet our customers’ needs but also contribute to the advancement of transformative technologies that are reshaping the energy landscape.

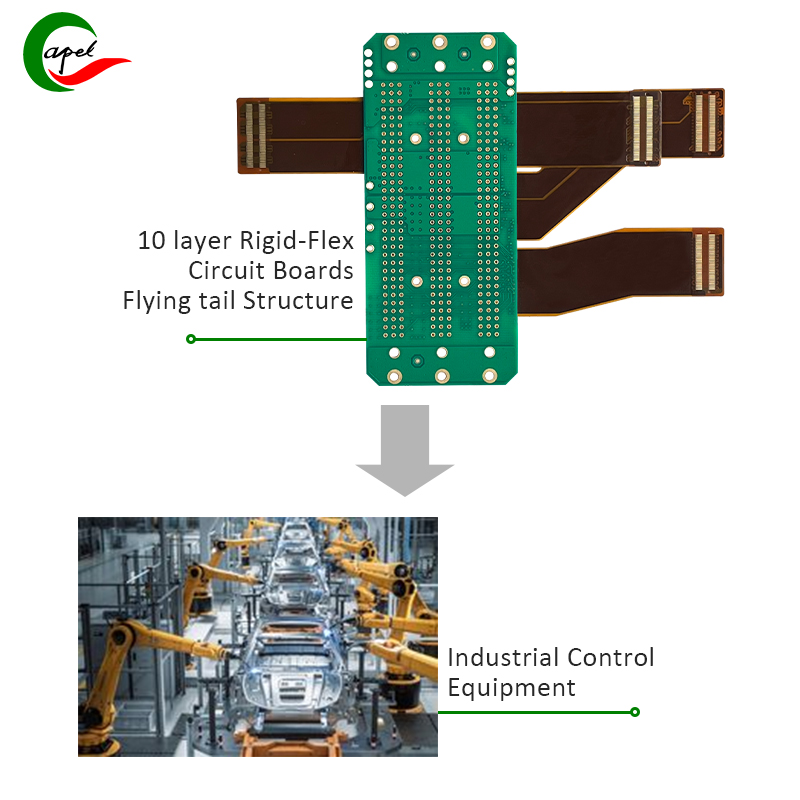

From improving the efficiency of renewable energy systems to enabling high power density energy storage solutions to drive the expansion of electric vehicle charging infrastructure, our unwavering commitment to pushing the boundaries of industrial control equipment PCB assembly technology reflects our efforts to advance industrial Controlling the enduring mission of progress and reliability. New energy sector. As the pace of innovation accelerates and the demand for sustainable, high-performance solutions continues to increase, we are steadfast in our pursuit of engineering excellence because we know that every breakthrough we achieve has the potential to shape the future of energy technology.

high precision industrial control flex pcb fabrication process

In summary

The latest industrial control PCB board design technology demonstrates the transformative power of innovation, reliability, and collaboration in the new energy field. As we navigate the complexities and opportunities of the future, we are prepared to continue delivering on the promise of the Best Performance Guarantee, providing our customers and partners with the technological edge they need to thrive in an era of unprecedented change and possibility.

By boldly tackling the challenges before us, we affirm our commitment to delivering groundbreaking solutions that transcend the norm and inspire the next generation of energy technologies. Let’s embark on a journey driven by innovation, purpose, and an unwavering pursuit of engineering excellence. The future of energy awaits us, as an industrial control PCBA manufacturer and we’re ready to shape it with the latest FR4 Industrial Control PCB Boards design technology.

Post time: Dec-29-2023

Back