The origin of flexible PCBs (FPC)

The history of flexible circuit boards can be traced back to the 1960s, when NASA began research on spacecraft to send humans to the moon. In order to adapt to the small space of the spacecraft, the internal temperature, humidity and strong vibration environment, a new electronic component is needed to replace the rigid circuit board – that is, the flexible circuit board (Flexible PCBs).

NASA has launched a number of studies to continuously study and improve the technology of flexible circuit boards. They gradually perfected this technology and applied it to the electronic systems of multiple spacecraft to ensure its long-term reliability and stability. Flexible PCBs technology has gradually extended to other fields and industries such as mobile phones, tablet computers, automobiles, and medical equipment, and has become an indispensable part of the modern electronics industry. It has had an important impact on the development of the electronics industry.

The definition of Flexible PCBs (FPC)

Flexible PCBs (also variously referred to around the globe as flex circuits, flexible printed circuit boards, flex print, flexi-circuits) are members of electronic and interconnection family. They consist of a thin insulating polymer film having conductive circuit patterns affixed thereto and typically supplied with a thin polymer coating to protect the conductor circuits. The technology has been used for interconnecting electronic devices since the 1950s in one form or another. It is now one of the most important interconnection technologies in use for the manufacture of many of today’s most advanced electronic products.

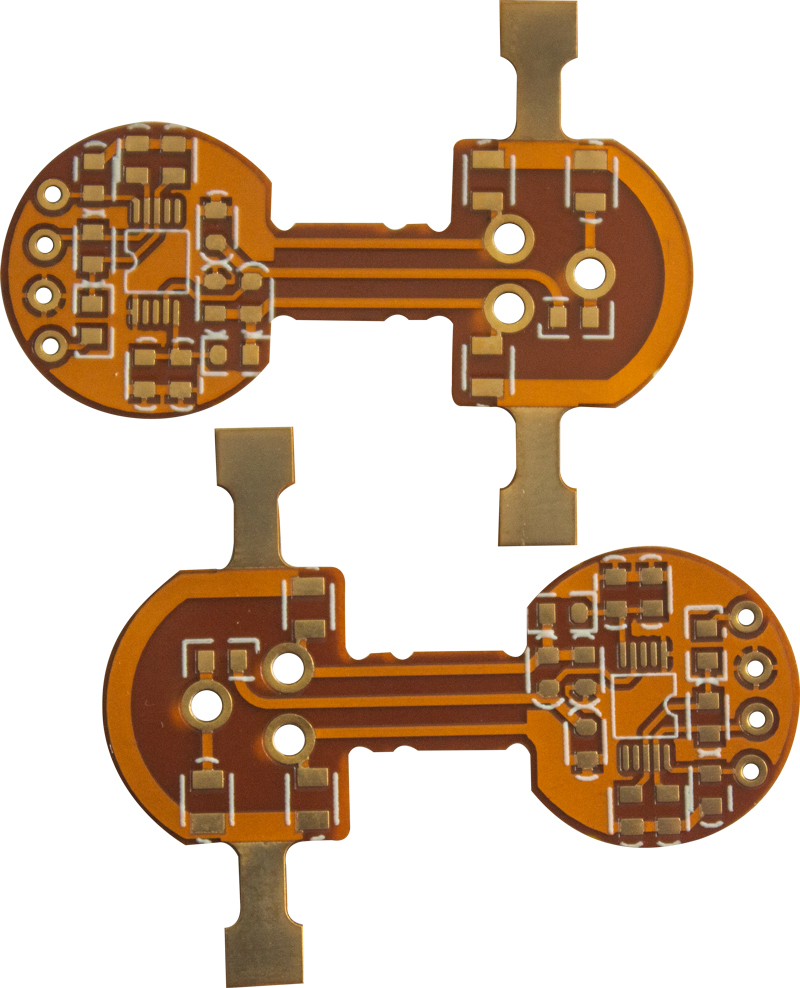

In practice there are many different kinds of flexible PCBs, including one metal layer, double sided, multilayer and rigid flex PCBs. The FPC can be formed by etching metal foil cladding (normally of copper) from polymer bases, plating metal or printing of conductive inks among other processes. Flexible circuits may or may not have components attached. When components are attached, they are considered by some in the industry to be flexible electronic assemblies.

Our company achieved mature technology in flexible PCBs in 2009

Shenzhen Capel Technology Co., Ltd. has been focusing on the R&D, design, production and sales of flexible PCBs (FPC) since 2009. It has mature production capacity of 1-16 layers of high-precision flexible PCBs (FPC), 2-16 layers of rigid-flex PCBs, impedance boards, and buried blind hole boards. It has new high-precision equipment such as drilling machines, laser machines, and direct imaging. Exposure machines, automatic screen printing machines, reinforcement machines, stamping machines, ensure the quality and delivery of each batch of our flexible PCBs (FPC), rigid-flex PCBs, impedance boards and buried blind via boards.

Post time: Jun-12-2023

Back