Date: 2025-07-02

Looking for a high-quality sweeping robot PCB? Capel offers cutting-edge rigid-flex printed circuit board technology to meet your needs.

Introduce

In the rapidly evolving world of robots, sweeping robots have become indispensable tools for maintaining cleanliness and order in homes and commercial spaces. These autonomous devices rely on cutting-edge technology to navigate and clean efficiently. A printed circuit board (PCB) is one of the key components that significantly improves the performance of sweeping robots. In this article, we will delve into the role of rigid-flexible PCB in enhancing the functionality of sweeping robots, and analyze through specific cases how Capel’s innovative PCB solutions have brought technological revolution to the sweeping robot industry.

Robot vacuum cleaners, also known as robot vacuum cleaners, are equipped with an array of sensors, motors, and control systems that allow them to navigate complex environments and perform cleaning tasks with precision. At the heart of these complex systems is the PCB, which acts as the robot’s central nervous system, facilitating communication between individual components and ensuring seamless operation.

Traditional rigid PCBs have limitations in adapting to the complex geometries and space constraints of robotic vacuum designs. This is where rigid-flex PCBs come into play. By combining the advantages of rigid and flexible PCBs, rigid-flex PCBs offer unparalleled flexibility in design and assembly, making them ideal for robotic vacuum applications.

Capel is a leading manufacturer of flexible and rigid-flex PCBs and has been at the forefront of driving innovation in the robotic vacuum industry. With over 16 years of experience developing custom PCB solutions for robot vacuums, Capel has become a trusted partner for robot vacuum manufacturers looking to improve product performance and reliability.

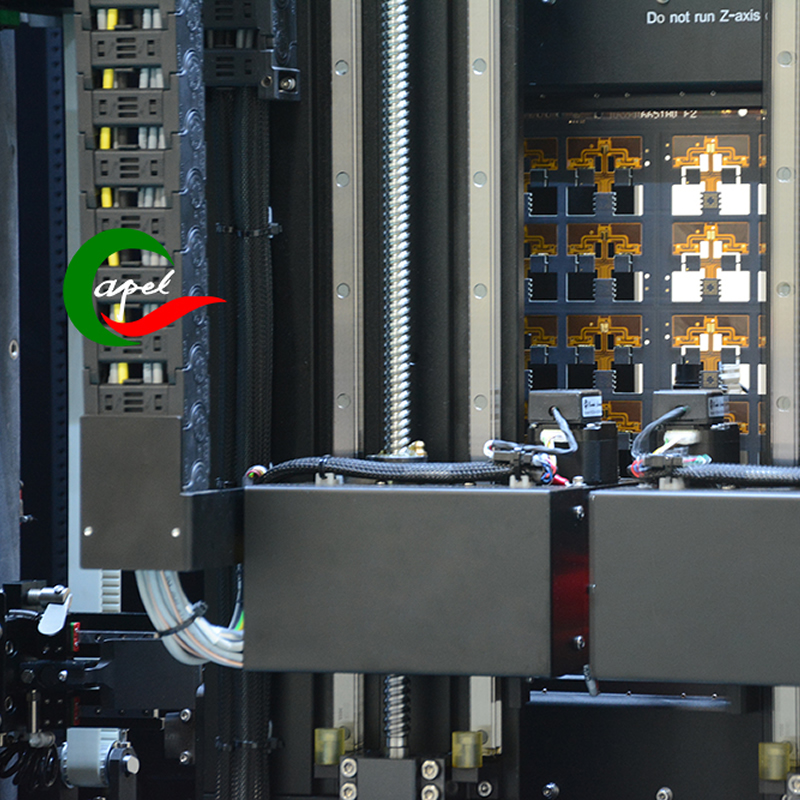

One concrete example of Capel’s impact on robot vacuum technology is the integration of its rigid-flex PCB into next-generation robot vacuum models. By utilizing Capel’s high-precision, high-density PCBs, robot vacuums are able to achieve unprecedented levels of efficiency and performance. Capel’s rigid-flexible combination of seamless integration of sensors, control systems, and power management modules on the PCB creates a sweeping robot that can navigate complex environments with greater precision and cleaning capabilities.

Technical Analysis: Advantages of Capel Rigid-Flex Board

Capel’s rigid-flex PCB offers several key benefits that directly improve the functionality of your robot vacuum. These include:

Space optimization: The unique design of the rigid-flexible PCB can effectively utilize the space inside the sweeping robot to integrate complex electronic components without affecting the overall size or performance.

Enhanced durability: The sweeping robot is subject to continuous movement and vibration during operation. Capel’s rigid-flex boards are engineered to withstand these environmental stresses, ensuring long-term reliability and durability.

Customization capabilities: Capel supports customized sweeping robot PCB solutions, providing design and assembly flexibility to meet the specific requirements of sweeping robot manufacturers.

Quality and Certifications: Capel’s rigid-flex boards are manufactured to the highest industry standards and have certifications such as IPC 3, UL, ROHS, ISO 14001:2015, ISO 9001:2015, and IATF16949:2016. This commitment to quality ensures that Capel PCB-equipped robot vacuums meet the most stringent performance and safety standards.

As robot vacuum technology continues to advance, the role of PCBs in driving innovation and performance cannot be underestimated. Capel’s relentless pursuit of excellence in flexible and rigid-flex PCB manufacturing, coupled with a deep understanding of robotic vacuum applications, makes it a key driver of future technological advancements in the industry.

In conclusion

In short, the integration of rigid-flex PCB significantly improves the functionality and performance of sweeping robots, paving the way for enhanced cleaning capabilities and operational efficiency. Capel’s expertise in developing custom PCB solutions for robotic vacuum cleaners has played a key role in driving innovation in this technology, setting a new benchmark for the industry. As robot vacuum manufacturers strive to deliver cutting-edge products that meet the ever-evolving needs of consumers, Capel’s rigid-flex PCBs stand out as key enablers of success in this dynamic and competitive market.

To sum up, Capel’s cooperation with sweeping robot manufacturers not only improves the performance of sweeping robots but also sets new standards for technological innovation in the industry. With a focus on high precision, durability, and customization capabilities, Capel’s rigid-flex PCBs are poised to continue shaping the future of robotic vacuum technology, driving technological advancements, and redefining the capabilities and potential of these indispensable cleaning devices.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..