If you are considering using a rigid-flex circuit board in your project, you may be wondering if you can stack components on both sides of the board. The short answer is – yes, you can. However, there are some important considerations to keep in mind.

In today’s ever-evolving technological environment, innovation continues to push the boundaries of what is possible. One area that has made significant progress in recent years is circuit boards. Traditional rigid circuit boards have served us well for decades, but now, a new type of circuit board has emerged – rigid-flex circuit boards.

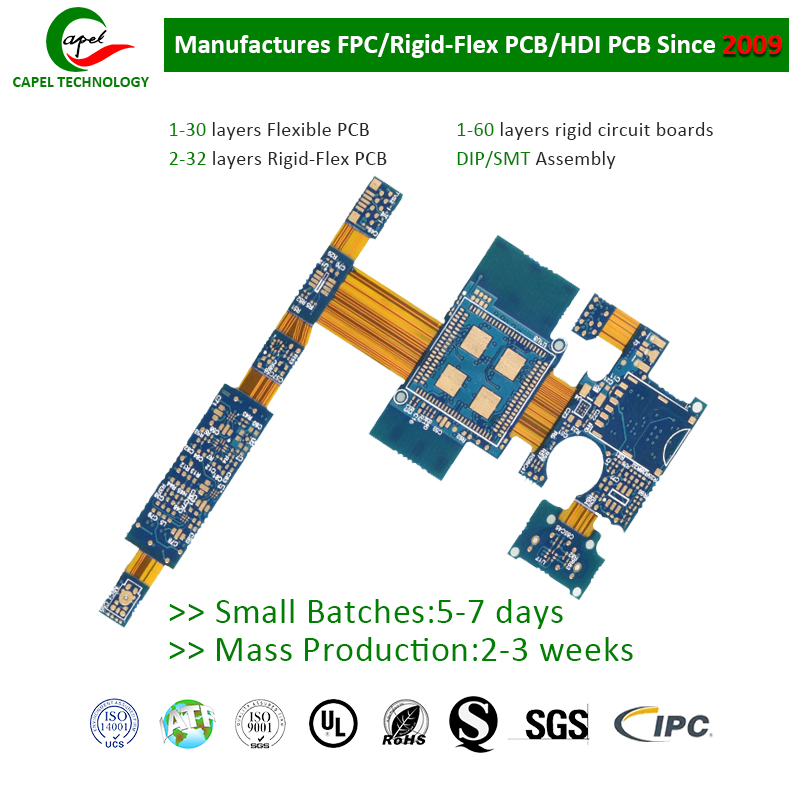

Rigid-flex circuit boards offer the best of both worlds. They combine the stability and strength of traditional rigid circuit boards with the flexibility and adaptability of flexible circuit boards. This unique combination makes rigid-flex boards the first choice for applications where space is limited or where the board needs to bend or conform to a specific shape.

One of the main advantages of rigid-flex circuit boards is their ability to accommodate multi-layer components. This means you can place components on both sides of the board, maximizing the available space. Whether your design is complex, requires high component density, or needs to integrate additional functionality, stacking components on both sides is a viable option.

However, it is important to ensure that the design and manufacturing processes enable correct assembly and functionality. Here are a few key points to consider when stacking components on both sides of a rigid-flex circuit board:

1. Size and weight distribution: Stacking components on both sides of a circuit board affects its overall size and weight. Careful consideration of size and weight distribution to maintain the structural integrity of the board is critical. Additionally, any additional weight should not impede the flexibility of the flexible portions of the board.

2. Thermal Management: Effective thermal management is critical to the proper operation and service life of electronic components. Stacking components on both sides affects heat dissipation. It is important to consider the thermal characteristics of the components and the circuit board itself to ensure effective heat dissipation and prevent overheating.

3. Electrical integrity: When stacking components on both sides of a rigid-flex circuit board, proper attention must be paid to electrical connections and signal integrity. The design should avoid signal interference and ensure proper grounding and shielding to maintain electrical integrity.

4. Manufacturing challenges: Stacking components on both sides of a rigid-flex circuit board can create additional challenges during the manufacturing process. Component placement, soldering, and assembly must be performed carefully to ensure the reliability and functionality of the circuit board.

When considering the feasibility of stacking components on both sides of a rigid-flex circuit board, it is recommended to consult with experienced designers and manufacturers. Their expertise can help you navigate complex design and manufacturing processes, ensuring the best possible outcome for your project.

In summary, rigid-flex circuit boards offer incredible versatility and innovation potential. The ability to stack components on both sides of the board can increase functionality and component density. However, to ensure successful implementation, factors such as size and weight distribution, thermal management, electrical integrity, and manufacturing challenges must be considered. By working with experienced professionals, you can take advantage of rigid-flex circuit boards and turn your ideas into reality.

Post time: Sep-20-2023

Back