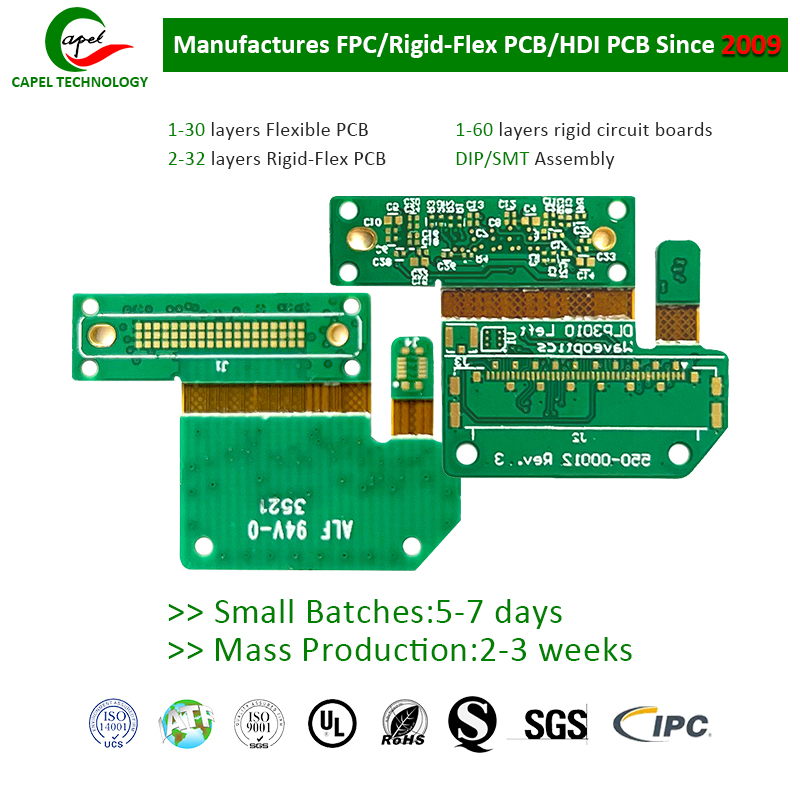

In the rapidly growing field of robotics and automation, the need for advanced electronic solutions is critical. Rigid-flex PCB are a solution that is getting a lot of attention. This innovative technology combines the best properties of rigid and flexible PCBs, making it ideal for complex applications in robotics and automation. This article explores the specific applications of rigid-flex PCBs in these areas, focusing on their role in connecting complex sensors and actuators, providing embedded control systems, and facilitating motion control solutions and data collection.

Connect complex sensors and actuators

One of the main applications of rigid-flex PCBs in robotics and automation is their ability to connect complex sensors and actuators. In modern robotic systems, sensors play a vital role in collecting environmental data, while actuators are crucial for executing precise movements. Rigid-flex PCBs are reliable interconnect solutions that enable seamless communication between these components.

The unique design of the rigid-flex PCB enables integration into compact spaces, which is often a requirement for robotic applications. By utilizing rigid and flexible sections, these PCBs can navigate the complex geometries of robotic structures, ensuring sensors and actuators are optimally positioned for maximum efficiency. This feature not only enhances the performance of the robotic system, it also reduces the overall weight and size of the electronic components, which is critical in applications where space and weight are at a premium.

Embedded control system

Another important application of rigid-flex PCBs in robotics and automation is their role in embedded control systems. These systems are the brains of a robotic device, processing data, making decisions, and executing commands. Rigid-flex PCBs provide the core control functions required by various smart devices, enabling them to meet the specific needs of robotics and automation equipment.

Integrating rigid-flex PCBs into embedded control systems enables a more streamlined design, reducing the number of interconnections and potential points of failure. This reliability is crucial in an automated environment, as downtime can result in significant losses. Additionally, the flexibility of these PCBs allows for the incorporation of multiple layers of circuitry to support the complex algorithms and processing tasks required for advanced robotics applications.

Provide motion control solutions

Motion control is an important aspect of robotics and automation, and rigid-flex PCBs play a vital role in providing effective solutions in this field. These PCBs integrate various motion control components such as motors, encoders and controllers into one compact assembly. This integration simplifies the design and assembly process, resulting in shorter production times and lower costs.

The ability of rigid-flex PCBs to bend and bend without affecting performance is particularly beneficial in dynamic environments where robots must navigate complex paths. This flexibility allows for the design of more complex motion control systems that can adapt to changing conditions in real time, thereby enhancing the overall functionality of the robotic system.

Data collection and processing

In the field of robotics and automation, data collection and processing are crucial to optimize performance and improve decision-making. Rigid-flex PCBs help integrate various data acquisition components, such as sensors and communication modules, into a single platform. This feature effectively collects data from multiple sources, which can then be processed to inform the robot’s actions.

The compact nature of rigid-flex PCBs means they can be easily integrated into tight spaces within robotic systems, ensuring data acquisition devices are optimally positioned for accurate readings. Additionally, high-density interconnects in rigid-flex designs enable faster data transfer rates, which are critical for real-time processing and response in automated systems.

Post time: Nov-09-2024

Back