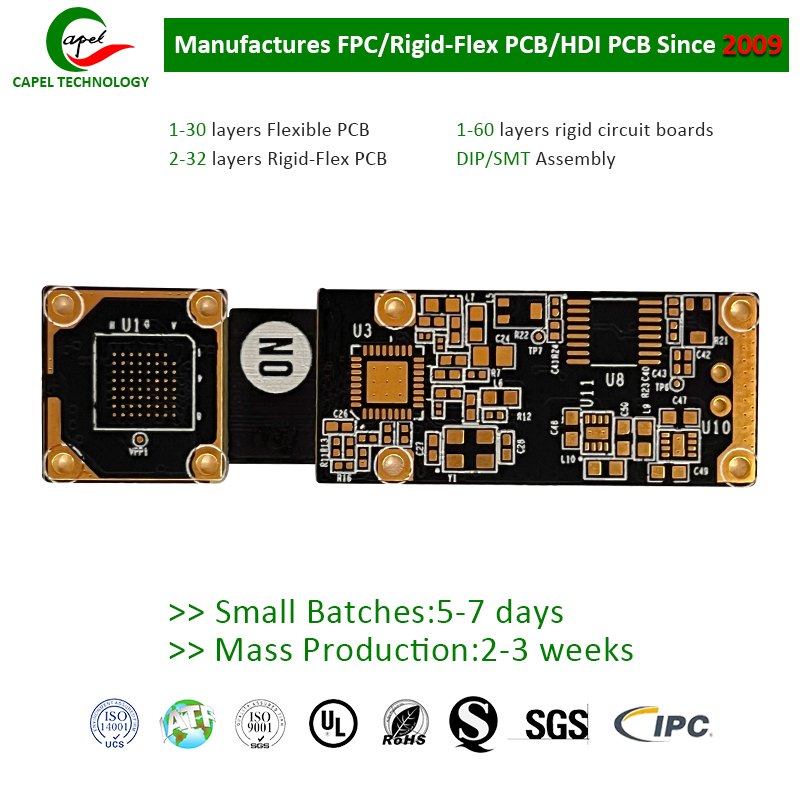

If you’re involved in electronics and printed circuit boards (PCBs), you’ve probably encountered common challenges with signal integrity and clock distribution. These issues can be difficult to overcome, but have no fear! In this blog post, we will explore how to solve signal integrity and clock distribution issues on 8-layer PCBs. To help you on your journey, we introduce Capel, a company with 15 years of experience in PCB manufacturing and providing strict quality control.

Signal integrity is an important aspect of PCB design as it ensures that the electrical signals transmitted within the PCB are not degraded or distorted. When signal integrity issues occur, data corruption, timing errors, and even system failures can occur. Therefore, it is crucial to effectively address these issues.

Clock distribution, on the other hand, refers to the process of transmitting clock signals throughout the PCB. Accurate clock distribution is critical for synchronization and timing within electronic systems. Poor clock distribution can cause various components to malfunction, leading to system failure or even complete failure.

Now, let’s dive into some techniques and guidance for solving these problems:

1. Layer stacking design: Carefully planned layer stacking is the basis for ensuring signal integrity and clock distribution. 8-layer PCBs provide greater flexibility when designing power and ground planes, helping to reduce noise and provide better signal integrity. Consider using separate power and ground planes for each signal layer and implementing reliable reference planes.

2. Impedance Control: Maintaining controlled impedance throughout the PCB is critical to signal integrity. Use an impedance calculation tool to determine the trace width and spacing required for the transmission line based on the PCB’s materials and stackup. With 15 years of PCB manufacturing experience, Capel can provide professional guidance and ensure precise impedance control.

3. Routing technology: Proper routing technology plays an important role in solving signal integrity and clock distribution issues. Using shorter traces minimizes signal propagation delays and reduces noise coupling. Use differential signaling for high-speed signals to enhance noise immunity. Additionally, length matching techniques are utilized to mitigate timing and synchronization issues.

4. Decoupling capacitors: Placing decoupling capacitors near integrated circuits (ICs) helps suppress noise and ensure power supply stability during high-frequency operation. Decoupling capacitors provide a low-impedance path to ground, minimizing voltage fluctuations and avoiding signal distortion.

5. EMI shielding: Electromagnetic interference (EMI) can seriously affect signal integrity and clock distribution. Implementing EMI shielding techniques, such as using a grounded shield can or adding conductive traces, can minimize EMI effects and improve overall performance.

Now that we have explored effective solutions to signal integrity and clock distribution problems, let’s introduce Capel – a company with extensive experience and strict quality control in PCB manufacturing. With 15 years of industry expertise, Capel understands the complexities of PCB design and can provide reliable solutions for your project.

Capel is committed to strict quality control to ensure that every PCB they manufacture meets the highest standards. From the initial design phase to final production, Capel uses a rigorous testing and inspection process to eliminate any potential signal integrity or clock distribution issues. Their team of experienced engineers can provide valuable insight and guidance to ensure your PCB project is a success.

In summary, solving signal integrity and clock distribution issues for an 8-layer PCB requires careful planning, the right design techniques, and the right expertise. Implementing strategies such as optimizing layer stacking, maintaining controlled impedance, using appropriate routing techniques, and incorporating EMI shielding techniques can significantly improve PCB performance. With a reliable partner like Capel, you can rest assured that your PCB will be manufactured with the highest quality and precision. So, embrace these solutions and make your next PCB project a success!

Post time: Oct-03-2023

Back