Unleash design freedom with flexible printed circuit boards Learn how flexible printed circuit boards (PCBs) are revolutionizing electronic design with their ability to accommodate large circuits in small spaces. Say goodbye to the limitations of rigid circuit boards and embrace the possibilities offered by flexible PCBs. Flexible PCBs, also known as flexible PCBs, offer designers and engineers unparalleled advantages. By breaking away from the constraints of rigid panels, they offer greater creative freedom and design flexibility. Gone are the days of compromising form for function, as flexible PCBs enable product designers to prioritize aesthetics and performance. Electrical engineers have two specific options when it comes to choosing a PCB that can adapt and bend into place: flexible PCBs and semi-flexible PCBs. Each type offers unique features and benefits to suit different design requirements and applications. Let’s delve into the significant differences between these two PCB types and explore their wide range of applications in modern electrical equipment.

Experience the advantages of semi-flexible PCB:

Discover the unparalleled performance of semi-flexible printed circuit boards (PCBs) and take your electronic designs to the next level. Get rid of the limitations of traditional flexible PCBs and embrace the cutting-edge technology of semi-flexible PCBs. What sets semi-flexible PCBs apart from their flexible PCB counterparts is their advanced structure. Unlike flexible PCBs, which are manufactured on flexible polymer film substrates, semi-flexible PCBs reach new levels of durability and resiliency. By integrating innovative circuit patterns into a solid substrate and reinforced with conductive materials and protective coatings, these boards combine the best of both worlds. This revolutionary design ensures not only flexibility but also unparalleled sturdiness, allowing the board to be easily bent and manipulated without any risk of damage. Unleash your creativity and take advantage of the endless possibilities offered by semi-flexible PCBs. Enhance your product design and performance with circuit boards that adapt to any shape or contour while maintaining the highest levels of reliability and durability. The future of electronic design is now – be the first to experience the benefits of semi-flexible PCBs.

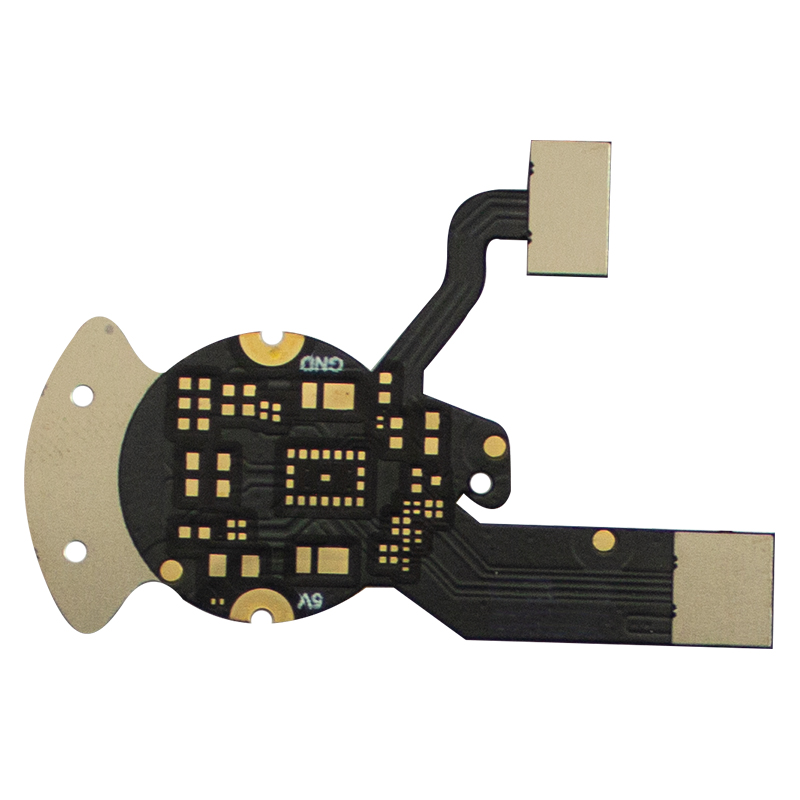

Introducing the game-changing semi-flexible PCB – the perfect combination of flexibility and precision. Unlike rigid PCBs, this cutting-edge technology allows flexing in carefully designated areas, ensuring optimal performance and reliability. Semi-flexible PCBs can be gracefully bent and shaped to fit your desired shapes and angles, so experience endless possibilities. The infographic below visually illustrates the extraordinary concept of this innovative PCB. Explore the future of design and engineering with the unparalleled capabilities of semi-flexible PCBs.

Introducing our revolutionary semi-flexible PCB – ideal for those looking for a balance between flexibility and stability. Our semi-flexible PCBs remain similar to traditional rigid PCBs but offer superior rigidity in addition to designated flexible areas. We use advanced techniques such as “controlled depth milling” or “milling” for precision manufacturing to subtly thin the FR4 material, making it exceptionally thin and flexible. Additionally, our tip treatment ensures that the flexible portion is protected from cracks, allowing for seamless bending with maximum freedom. Experience the best of both worlds with our game-changing semi-flexible PCBs, designed to exceed your expectations.

Learn about our innovative approach to semi-flexible PCBs using cutting-edge thin-core laminates. With ultra-thin laminates that are only 0.005 mil thick, we have optimized the process to perfectly suit static bending applications. For added durability and flexibility we recommend using RA (roll annealed) copper foil, specifically selected to resist cracking and provide truly strong flexibility. Experience next-level reliability and performance with our superior semi-flexible PCBs.

Take advantage of our cutting-edge semi-flexible and flexible PCBs to meet your design needs. Dive into the key differences of semi-flexible PCBs designed to deliver unparalleled performance. Unlike traditional flexible PCBs that can withstand countless bends without being damaged, semi-flexible PCBs have limited bending capabilities. Repeated bending may cause cracks or breakage, making it ideal for curved installation applications. However, most semi-flexible boards can still withstand multiple bends for worry-free installation and future maintenance. Just make sure the PCB doesn’t bend excessively to minimize any potential risk of damage. Experience the pinnacle of versatility and reliability with our state-of-the-art semi-flexible PCBs.

Discover the endless benefits offered by our revolutionary semi-flexible PCBs, tailor-made for our customers.

With its superior space-saving capabilities, semi-flexible PCBs can be easily optimized for tight environments, just like flex boards. Seamlessly bend and maneuver these boards during installation to easily accommodate larger boards in compact spaces. Rest assured, our semi-flexible PCBs are crafted with unwavering reliability to ensure your designs run flawlessly. Experience the ultimate combination of space-saving potential and maximum reliability with our top-of-the-line semi-flexible PCBs.

Ensure quality while staying on budget with our advanced semi-flexible PCBs. Say goodbye to the skyrocketing costs associated with flexible circuit boards, because our semi-flexible PCBs can deliver significant cost savings that will keep you smiling all the way to the bank. Wondering how we achieve such impressive flexibility without spending too much money? By cleverly reducing the thickness of the FR4 material using our expert-controlled deep milling technology, we produce the flexible portion of the board at extremely low cost. No need to worry about performance degradation, either – our semi-flexible PCBs ensure unparalleled durability and reliability. While we understand that the bending ability of a flexible PCB may be indispensable in some situations, for cost-conscious consumers like you, it makes sense to use our cost-effective semi-flexible PCBs whenever possible. Enhance your designs, maximize cost savings and dominate with our superior semi-flexible PCB solutions.

Become an expert in designing the most advanced and reliable semi-flexible PCBs with our comprehensive guide.

We know that manufacturing high-quality, durable semi-flexible PCBs can seem like a daunting task, but don’t worry! We’re here to guide you through the process and provide you with insider knowledge on best practices. Our time-tested rules will ensure your designs not only meet but exceed industry standards for robustness and reliability. Whether you are an experienced electrical engineer or a novice hobbyist, keeping these general rules in mind will simplify your semi-flexible PCB design and guide you to success. Don’t settle for mediocrity – unlock the full potential of your designs and conquer the market with our expert-recommended guides.

One important rule above all others: the flexible portion of the board must maintain a consistent running direction along the X or Y plane. Taking the risk of building a board with flex areas in the X and Y directions comes with a higher cost because it requires additional manufacturing steps. By adhering to this basic principle, you can save money and streamline production, ensuring that your PCBs are not only flexible but also cost-effective. Don’t compromise on quality or break the bank – keep your design focused on a single direction of operation to maximize efficiency and minimize expense. Your customers will appreciate the performance and price of your perfectly executed motherboards.

In the exciting world of semi-flexible PCB design, component hole placement is key to success. Precision must be maintained and one golden rule must be followed: leave at least one millimeter of clearance between any component holes on the PCB and the flex area. By following this wise guide, you will reap many benefits. You can ensure your PCB remains flexible, reducing the risk of damage or failure. Additionally, this careful spacing allows for a smooth manufacturing and assembly process, saving you time and resources. So don’t let your design fall short – incorporate this rule of thumb and create a semi-flexible PCB that not only performs flawlessly, but also impresses your customers with its durability and efficiency.

Attention, dear designers! It is critical to develop a board layout strategy to achieve a single milling process that provides perfectly thinned FR4 material for the flex areas. Multiple passes are dangerous work and can introduce weak links that can cause trouble when bending the board during installation or maintenance. Our innovative approach ensures seamless and resilient results, eliminating any worries and providing a worry-free experience. Trust our expertise to deliver top-notch design that guarantees functionality and convenience.

Discover the perfect solution for your circuit board needs – semi-flexible PCBs!

Designed for scenarios where bending is only required for installation and long-term maintenance. Embrace their flexibility in applications where space is at a premium. However, if the curved portion of the board is expected to be subject to dynamic stress, don’t worry! Choose a flexible PCB with unparalleled flexibility. Don’t settle for less when it comes to reliability – make the right choice for your project with our cutting-edge products.

Explore the wide range of application possibilities for semi-flexible PCBs as they power industries ranging from automotive to industrial equipment to security electronics. There are many factors to consider when determining the ideal circuit board for your project. You have to consider the space available, the level of stress placed on the board, the thermal performance required, and of course, your budget. Proper selection of PCB type is crucial to ensure successful engineering and flawless production of electronic products. For a more in-depth look at the incredible capabilities of our PCB varieties, feel free to contact us. We’re eager to help you every step of your journey.

Post time: Sep-12-2023

Back