In this blog post, we’ll explore the benefits, challenges, and feasibility of using rigid-flex circuit boards in automotive design and production.

In today’s fast-paced technology environment, automakers continually strive to stay ahead of the curve and maximize vehicle performance, reliability and functionality. One major development that has revolutionized the industry is the integration of rigid-flex circuit boards. These unique circuit boards offer several advantages that make them ideal for automotive applications.

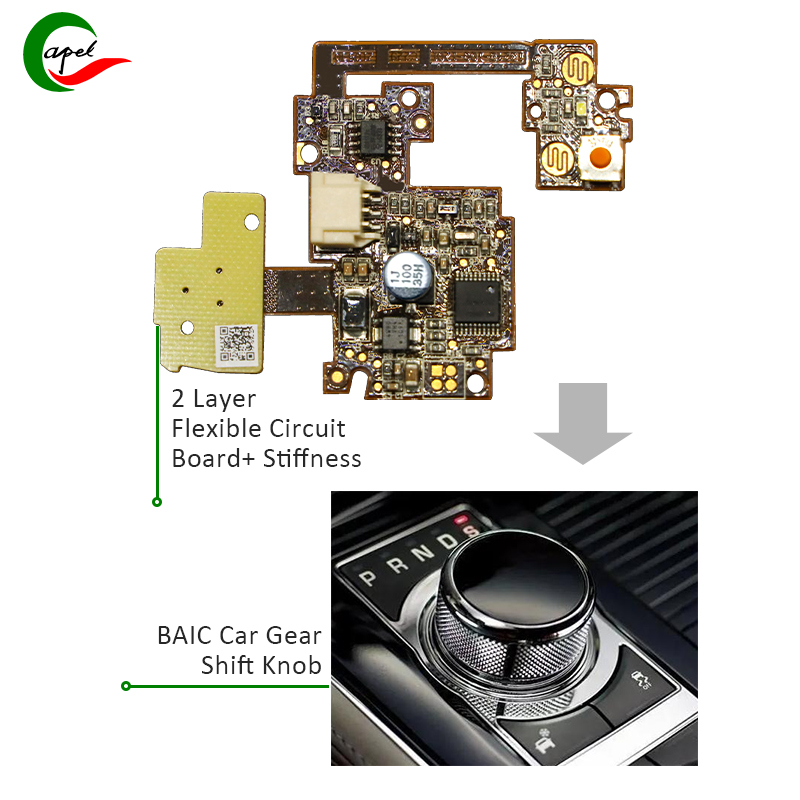

To understand the role of rigid-flex circuit boards in the automotive world, we first need to define what they are. Rigid-flex circuit boards combine the best of both worlds by seamlessly integrating rigid and flexible components onto a single board. This hybrid structure offers several advantages over traditional rigid or flexible circuit boards, making it ideal for automotive applications.

One of the main benefits of using rigid-flex circuit boards in the automotive industry is their ability to withstand harsh environments. Automotive applications expose electronic components to extreme temperatures, vibration and mechanical stress. Rigid-flex circuit boards offer excellent resistance to these environmental factors, ensuring the integrity and reliability of vehicle electronic systems. In addition, its compact, lightweight design enables efficient use of space within the limited confines of a car interior.

Another advantage of rigid-flex circuit boards is their enhanced reliability. The combination of rigid and flexible materials eliminates the need for connectors and solder joints, reducing the risk of failure due to loose connections or solder fatigue. This increases the overall durability and longevity of the circuit board, making the vehicle stronger and less prone to electrical failure.

Additionally, the flexibility of rigid-flex boards allows designers to optimize layout and reduce interconnect count, thereby improving signal integrity and reducing electromagnetic interference (EMI). As automotive electronic systems continue to increase in complexity, maintaining signal integrity is critical to ensuring efficient, error-free communication between different components. Rigid-flex circuit boards provide an effective solution to this challenge, facilitating seamless integration of various electronic modules and improving overall system performance.

The integration of rigid-flex circuit boards also saves significant costs for the automotive industry. By eliminating the need for additional connectors and reducing the number of interconnections, manufacturers can streamline production processes and reduce assembly time, ultimately lowering production costs. Additionally, the increased reliability of these boards reduces the need for costly repairs and replacements, thereby extending life cycles and reducing maintenance expenses.

However, despite its numerous advantages, there are certain challenges associated with implementing rigid-flex circuit boards in automotive applications. The unique construction of these boards requires specialized manufacturing techniques and expertise, which can increase initial production costs. However, as demand for rigid-flex circuit boards continues to grow in the automotive industry, economies of scale may reduce production costs, making them a more economically viable option in the long run.

In addition, the automotive industry’s stringent quality and safety standards require thorough testing and verification of all components, including circuit boards. Rigid-flex panels must undergo rigorous reliability testing to ensure they can withstand the harsh conditions faced in vehicles. The testing process can be time-consuming and can create time-to-market challenges for automakers. However, the benefits of increased reliability and performance outweigh the potential time constraints, making rigid-flex boards a valuable solution in automotive design and production.

In summary, the integration of rigid-flex circuit boards opens up new possibilities for the automotive industry, improving vehicle performance, reliability and functionality. These boards perform well in harsh environments, providing superior reliability, optimized signal integrity and cost savings. Despite challenges such as specialized manufacturing techniques and stringent testing requirements, the numerous advantages of rigid-flex circuit boards make them an excellent choice for automotive applications. As technology continues to advance, we expect these innovative circuit boards to play an increasingly important role in the automotive industry.

Post time: Sep-19-2023

Back