In this blog post, we’ll explore the factors to consider when selecting film materials for flexible PCBs and provide valuable insights to help you make an informed decision.

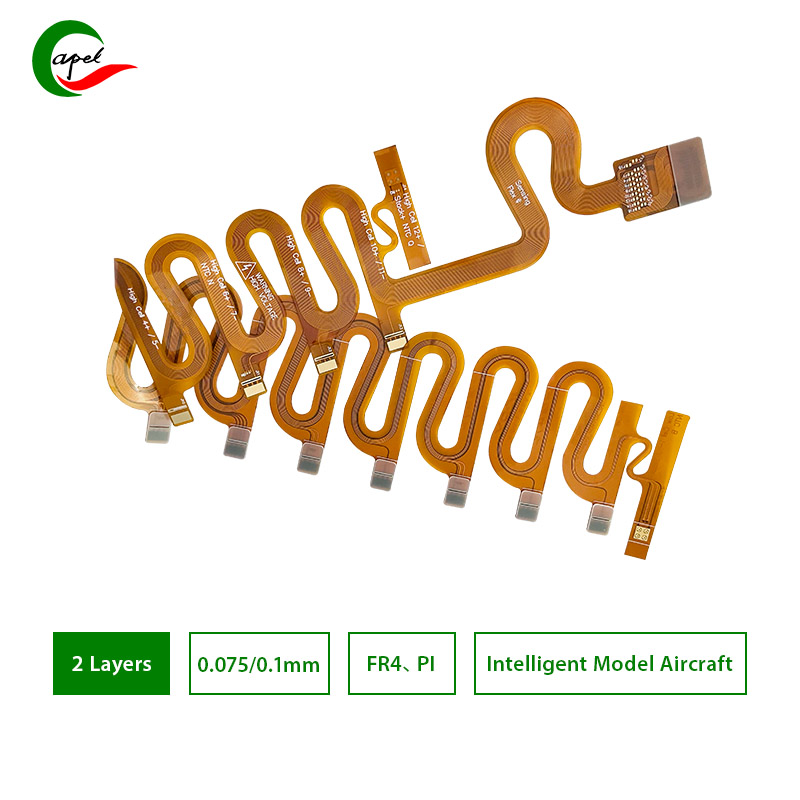

In recent years, flexible PCBs (flexible printed circuit boards) have gained popularity due to their ability to conform to complex shapes, improve electrical performance, and reduce weight and space requirements. These flexible circuit boards are widely used in various industries, including automotive, consumer electronics, medical devices and aerospace. A key aspect of designing flexible PCBs is selecting the appropriate film material to ensure the required performance and reliability.

1. Flexibility and bending :

Flexible PCBs are known for their flexibility and ability to bend. Therefore, thin-film materials used to build such circuits must have excellent flexibility and bendability. One commonly used material is polyimide film (PI). Polyimide has excellent mechanical properties such as high tensile strength, good thermal stability and excellent chemical resistance, making it ideal for flexible PCB applications. In addition, liquid crystal polymer (LCP) films are also popular for their excellent flexibility and excellent dimensional stability.

2. Dielectric constant and loss factor :

The dielectric constant and dissipation factor of the film material play a crucial role in determining the performance of flexible PCBs. These properties provide insight into the material’s ability to transmit electrical signals without significant losses. Low dielectric constant and dissipation factor values are ideal for high-frequency applications because they minimize signal loss and ensure reliable performance. Some commonly used low dielectric constant film materials are polyimide and LCP.

3. Thermal stability and heat resistance :

Flexible PCBs are frequently exposed to changing temperature conditions, especially in automotive and aerospace applications. Therefore, selecting film materials with excellent thermal stability and resistance is critical to ensure optimal performance and reliability. High-temperature polyimide films, such as Kapton®, are widely used in flexible PCB manufacturing due to their ability to withstand extreme temperatures while maintaining structural integrity. LCP films, on the other hand, have similar thermal stability and can be considered as alternatives.

4. Chemical compatibility:

Thin film materials used in flexible PCBs must be chemically compatible with the specific environment in which they are deployed. During PCB assembly and handling, exposure to substances such as solvents, cleaners, and fluxes must be considered. Polyimide has excellent chemical resistance and is the first choice for most flexible PCB applications.

5. Adhesive compatibility:

Thin film materials are often laminated with adhesive layers to create a strong structure in flexible PCBs. Therefore, it is crucial to select a film material that is compatible with the chosen adhesive system. The material should bond well with the adhesive to ensure a strong bond and maintain the integrity of the flexible PCB. Before finalizing the film material, it is recommended that specific adhesive systems be tested for compatibility to ensure reliable bonding.

6. Availability and Cost:

Finally, film material availability and cost should also be considered in the selection process. While polyimide is widely available and cost-effective, other materials such as LCP can be relatively more expensive. Evaluating project requirements, budget constraints, and market availability will help determine the best film material for your flexible PCB design.

In summary, choosing the right film material for your flexible PCB is critical to ensuring optimal performance, reliability and long-term durability. Factors such as flexibility and bendability, dielectric constant and loss factor, thermal stability and resistance, chemical compatibility, adhesive compatibility, and availability and cost should be carefully evaluated during the selection process. By considering these aspects and conducting in-depth research, you can make an informed decision that will lead to a well-designed, high-quality flexible PCB for your specific application.

Post time: Sep-21-2023

Back