Date: 2025-07-02

Now PCB factories need to provide more and more services, Kaboer is the industry leader. With 16 years of production experience, Kaboer can provide one-stop service and provide the most perfect production solutions for more and more customers. As a result, FPC manufacturing has become a critical component of the electronics supply chain. Among the key players in this field is Kaboer Technology Co., Ltd., a company renowned for its innovative prototyping services and advanced component assembly FPC capabilities. This article explores the significance of prototyping services in FPC manufacturing, the assembly process, and how Kaboer Technology Co., Ltd. stands out in the industry.

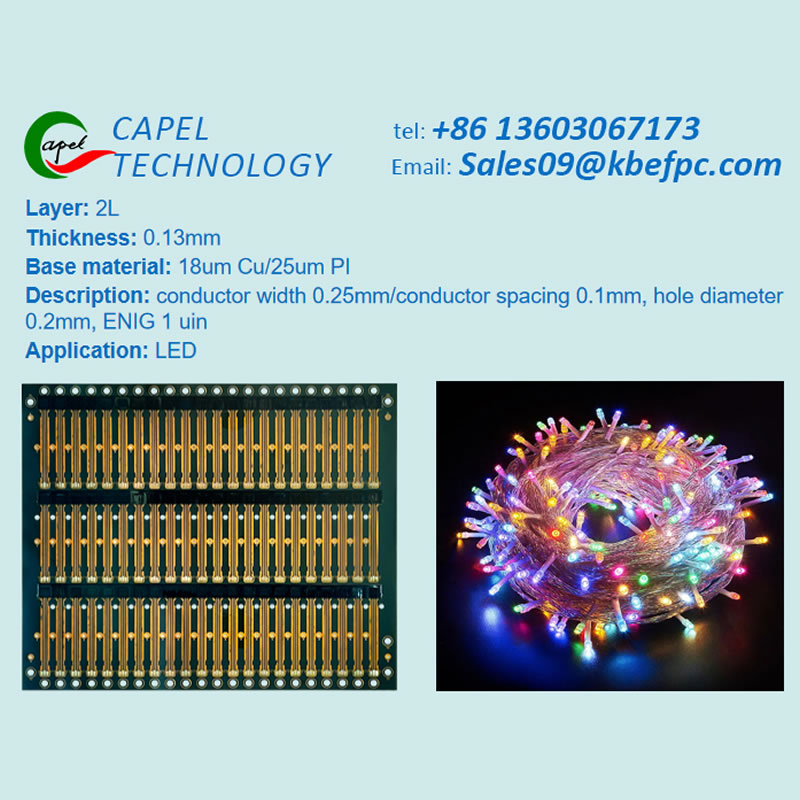

Flexible printed circuits (FPC) are essential in modern electronics, offering a unique combination of flexibility, lightweight design, and high-density interconnections. These circuits are used in various applications, from consumer electronics to medical devices and automotive systems. The manufacturing process of FPC involves several stages, including material selection, circuit design, etching, and lamination. However, before mass production can commence, prototyping is a crucial step that allows engineers and designers to test and validate their designs.

Prototyping services play a pivotal role in the FPC manufacturing process. They allow companies to create small batches of flexible circuits to evaluate their performance, functionality, and manufacturability. This iterative process helps identify potential issues early on, reducing the risk of costly errors during mass production.

Rapid Iteration: Prototyping enables rapid iteration of designs. Engineers can quickly modify and test different configurations, materials, and layouts, ensuring that the final product meets all specifications.

Cost Efficiency: By identifying design flaws during the prototyping phase, companies can save significant costs associated with rework and redesign during mass production.

Performance Testing: Prototypes allow for rigorous testing under real-world conditions. This ensures that the FPC will perform reliably in its intended application.

Customization: Prototyping services offer the flexibility to customize designs according to specific client requirements, making it easier to cater to niche markets.

Kaboer Technology Co., Ltd. has established itself as a leader in the FPC manufacturing sector, particularly in the realm of prototyping services. With a commitment to quality and innovation, Kaboer Technology has developed a robust prototyping service that caters to a diverse range of industries.

One of the key advantages of Kaboer Technology is its state-of-the-art Surface Mount Technology (SMT) plants. These facilities are equipped with the latest machinery and technology, enabling precise and efficient component assembly FPC. The integration of advanced SMT processes ensures that components are placed accurately on the flexible circuits, enhancing the overall reliability and performance of the final product.

Kaboer Technology’s assembly process is designed to be both efficient and adaptable. The company employs a combination of automated and manual assembly techniques, allowing for flexibility in production volumes. This hybrid approach ensures that even small batches can be produced with the same level of quality and precision as larger runs.

Design Collaboration: Kaboer Technology works closely with clients during the design phase, providing valuable insights and recommendations to optimize the FPC layout for assembly.

Quality Control: Rigorous quality control measures are implemented throughout the assembly process. This includes inspections at various stages to ensure that each component is correctly placed and functioning as intended.

Testing and Validation: Once the assembly is complete, prototypes undergo extensive testing to validate their performance. This includes electrical testing, thermal cycling, and mechanical stress tests to ensure durability and reliability.

Feedback Loop: Kaboer Technology values client feedback and uses it to refine and improve its prototyping services continually. This commitment to customer satisfaction has earned the company a reputation for excellence in the industry.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..