Introduce:

In electronics manufacturing, soldering plays a vital role in ensuring the reliability and performance of printed circuit boards (PCBs). Capel has 15 years of industry experience and is a leading provider of advanced PCB soldering solutions. In this comprehensive guide, we’ll explore the various soldering processes and techniques used in PCB manufacturing, highlighting Capel’s expertise and advanced process technology.

1. Understanding PCB soldering: Overview

PCB soldering is the process of joining electronic components to a PCB using solder, a metal alloy that melts at low temperatures to form a bond. This process is crucial in PCB manufacturing as it ensures electrical conductivity, mechanical stability and thermal management. Without proper soldering, the PCB may not work or perform poorly.

There are many types of soldering techniques used in PCB manufacturing, each with its own applications based on the specific requirements of the PCB. These technologies include surface mount technology (SMT), through hole technology (THT) and hybrid technology. SMT is typically used for small components, while THT is preferred for larger and more robust components.

2. PCB welding technology

A. Traditional welding technology

Single and double-sided welding

Single-sided and double-sided soldering are widely used techniques in PCB manufacturing. Single-sided soldering allows components to be soldered on only one side of the PCB, while double-sided soldering allows components to be soldered on both sides.

The single-sided soldering process involves applying solder paste to the PCB, placing the surface mount components, and then reflowing the solder to create a strong bond. This technology lends itself to simpler PCB designs and offers advantages such as cost-effectiveness and ease of assembly.

Double-sided soldering, on the other hand, involves using through-hole components that are soldered to both sides of the PCB. This technology increases mechanical stability and allows for the integration of more components.

Capel specializes in implementing reliable single- and double-sided welding methods, ensuring the highest quality and precision in the welding process.

Multilayer PCB soldering

Multilayer PCBs are composed of multiple layers of copper traces and insulating materials, requiring specialized soldering techniques. Capel has extensive experience handling complex multi-layer welding projects, ensuring reliable connections between the layers.

The multilayer PCB soldering process involves drilling holes into each layer of the PCB and then plating the holes with conductive material. This allows components to be soldered on the outer layers while maintaining connectivity between the inner layers.

B. Advanced welding technology

HDI PCB soldering

High-density interconnect (HDI) PCBs are becoming increasingly popular due to their ability to accommodate more components in smaller form factors. HDI PCB soldering technology enables precise soldering of micro-components in high-density layouts.

HDI PCBs face unique challenges such as tight component spacing, fine-pitch components, and the need for microvia technology. Capel’s advanced process technology enables precise HDI PCB soldering, ensuring the highest quality and reliability for these complex PCB designs.

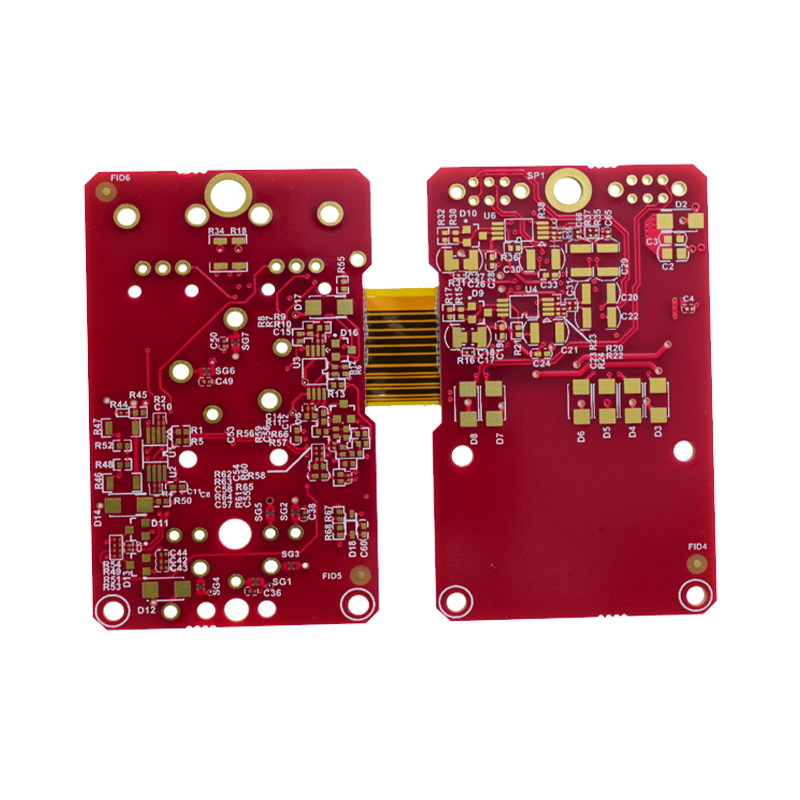

Flexible board and rigid-flex board welding

Flexible and rigid-flex printed circuit boards offer flexibility and versatility in design, making them ideal for applications that require bendability or compact form factors. Soldering these types of circuit boards requires specialized skills to ensure durability and reliability.

Capel’s expertise in soldering flexible and rigid-flex PCBs ensures that these boards can withstand repeated bending and maintain their functionality. With advanced process technology, Capel achieves reliable solder joints even in dynamic environments that require flexibility.

3. Capel’s advanced process technology

Capel is committed to staying at the forefront of the industry by investing in state-of-the-art equipment and innovative approaches. Their advanced process technology enables them to provide cutting-edge solutions for complex welding requirements.

By combining advanced soldering equipment such as automatic placement machines and reflow ovens with skilled craftsmen and engineers, Capel consistently delivers high-quality soldering results. Their commitment to precision and innovation sets them apart in the industry.

In summary

This comprehensive guide provides an in-depth understanding of PCB soldering processes and techniques. From traditional single-sided and double-sided soldering to advanced technologies such as HDI PCB soldering and flexible PCB soldering, Capel’s expertise shines through.

With 15 years of experience and commitment to advanced process technology, Capel is a trusted partner for all PCB soldering needs. Contact Capel today for reliable, high-quality PCB soldering solutions, backed by their craftsmanship and proven technology.

Post time: Nov-07-2023

Back