Revolutionizing MRI machines with advanced flexible PCB technology. Enhance MRI system performance and reliability. Upgrade your MRI machine with cutting-edge flexible PCB technology.

Revolutionary MRI Technology: The Role of Flexible PCBs in Advancing Medical Imaging

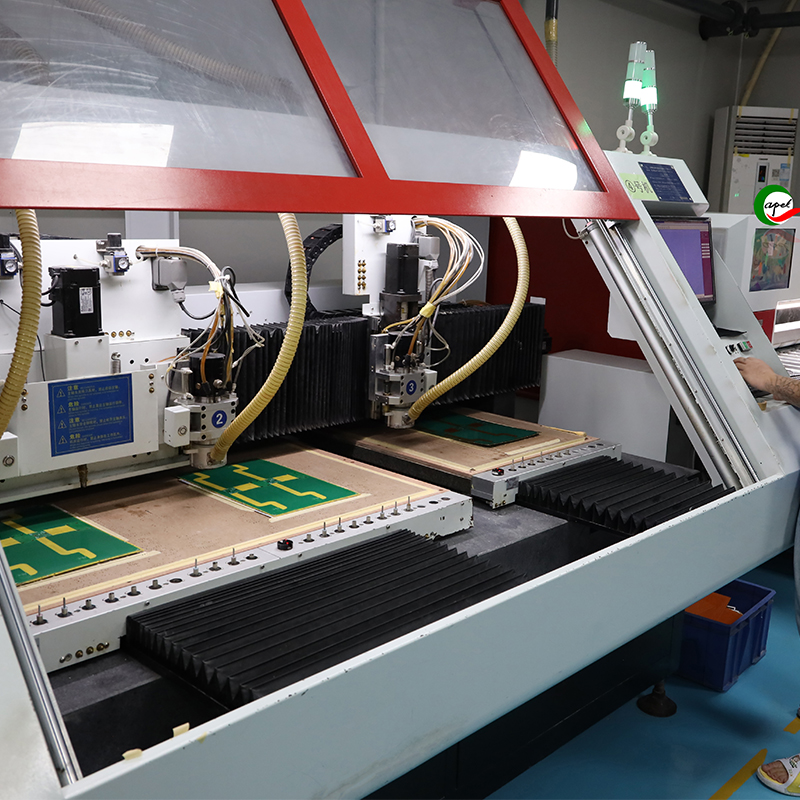

In the ever-evolving field of medical technology, there is a growing demand for more advanced and efficient MRI machines. As the industry seeks to improve the functionality and precision of these important medical devices, the role of flexible printed circuit boards (PCBs) is becoming increasingly important. Capel, a leading manufacturer with 16 years of experience in producing high-quality PCBs, has been at the forefront of this revolution. Capel plays an important role in improving the performance and reliability of MRI machines by leveraging its expertise in flexible PCB and rigid-flex PCB manufacturing.

Advancing MRI capabilities with Capel’s innovative flexible PCB technology

The integration of flexible PCB technology significantly improves the functionality of MRI machines, enabling higher imaging accuracy and density. Capel’s flexible PCBs are designed to meet the specific requirements of MRI machines, providing the high precision and quality that are essential for the accurate and reliable operation of these critical medical devices. Capel focuses on innovation and advanced manufacturing technology and has obtained a total of 36 utility model patents and invention patents, reflecting their commitment to pushing the boundaries of PCB technology.

Custom Flexible PCB Solution for Enhanced MRI Machine Integration | Capel’s Quality Assurance and Compliance

One of the main advantages of Capel flexible PCB is its ability to support customized 1-30 layer MRI machine flexible PCB and 2-32 layer MRI machine rigid-flex PCB. This level of customization allows seamless integration of the PCB into the MRI machine, ensuring optimal performance and functionality. In addition, Capel’s flexible PCBs have received IPC 3, UL and ROHS marks, and the company has received ISO 14001:2015, ISO 9001:2015 and IATF16949:2016 certifications, underscoring their commitment to maintaining the highest quality and compliance standard.

Comprehensive PCB solutions for MRI machines: Capel’s expertise in manufacturing and assembly

Capel’s expertise extends beyond PCB manufacturing, the company also offers PCB assembly services, providing a comprehensive solution to MRI machine manufacturers. With its own flexible PCB and rigid-flex PCB factories and assembly capabilities, Capel is able to streamline the production process and ensure seamless integration of PCBs into MRI machines. This end-to-end approach not only improves efficiency but also ensures the highest level of quality control throughout the manufacturing process.

Driving innovation in MRI technology: Leveraging Capel’s advanced flexible PCB solutions

The impact of advanced flexible PCB technology on MRI machines cannot be overstated. By partnering with a trusted and experienced manufacturer like Capel, MRI machine manufacturers can take advantage of the latest advances in PCB technology to improve the performance and reliability of their products. With a deep understanding of the unique requirements of MRI machines, Capel is well-positioned to continue driving innovation in the medical technology industry, ultimately improving patient care and outcomes.

Revolutionizing MRI machines with advanced flexible PCB technology: Capel takes a leading role in shaping the future of medical devices

In summary, the integration of advanced flexible PCB technology has revolutionized the capabilities of MRI machines, enabling higher imaging accuracy and density. Capel’s expertise in flexible PCB and rigid-flex PCB manufacturing, coupled with their commitment to innovation and quality, makes them a leading partner for MRI machine manufacturers. As the demand for more advanced and efficient medical devices continues to grow, Capel’s commitment to pushing the boundaries of PCB technology will undoubtedly play a key role in shaping the future of the industry.

Post time: May-11-2024

Back