Explore the world of military PCB and flex PCB technology through the eyes of an experienced flex PCB engineer with 16 years of experience in the military flex PCB and defense FPC manufacturing industry. Learn how Capel’s custom solutions are revolutionizing the industry, bringing technological innovation into the field and solving industry-specific challenges for military customers. Gain insights from successful case studies and in-depth analysis, and learn about the benefits Capel’s military flexible PCBs bring.

1. Introduce:

As an experienced flex PCB engineer with 16 years of experience in the military flex PCB and defense FPC manufacturing industry, I have witnessed the evolution of technology and its impact on the defense sector. In this article, I’ll take a deep dive into the world of military PCB and flexible PCB technology and how Capel’s custom solutions are revolutionizing the industry. Through successful case studies and in-depth analysis, we will explore the challenges faced by military customers and how Capel’s military flexible PCBs bring technological innovation to the field.

2. The evolution of military PCB and flexible PCB technology:

The military and defense sectors are always at the forefront of technological advancement, and there is an ever-present need for high-performance, reliable and durable electronic components. This is where the role of military PCB and flexible PCB technology becomes critical. Due to the need for compact, lightweight, and rugged electronic systems, traditional rigid PCBs are often inadequate for the harsh environments in which military equipment operates.

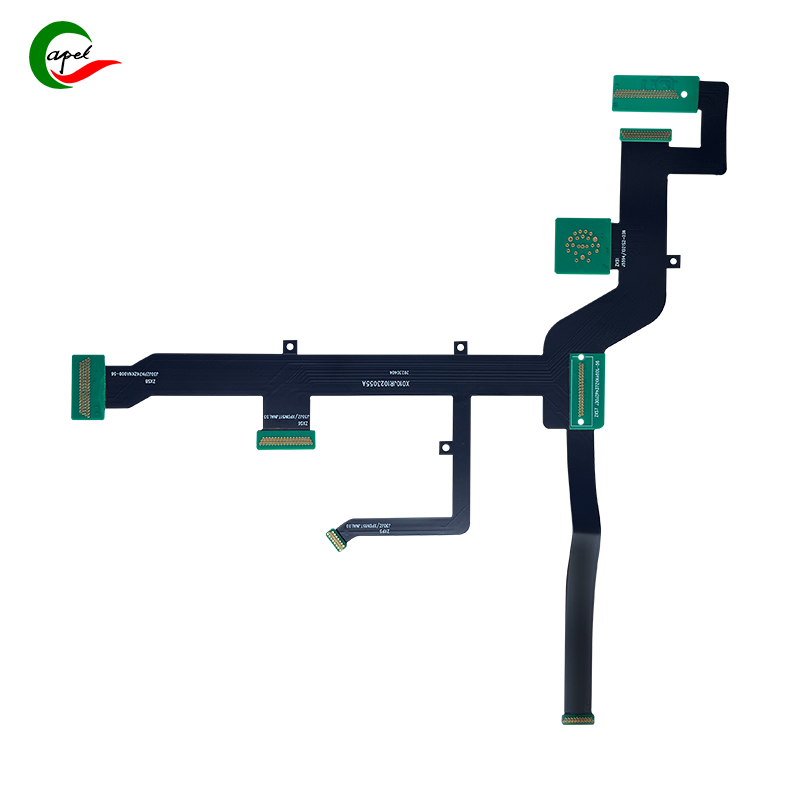

This is where flexible PCB technology comes into play. Flexible PCBs have the ability to bend, twist and adapt to irregular shapes, providing versatility and durability that rigid PCBs cannot match. This makes them ideal for military applications where space is limited and reliability is critical.

3. Challenges facing the military and defense FPC manufacturing industry:

Military and defense FPC manufacturing faces unique challenges that require specialized solutions. From extreme temperatures and harsh environmental conditions to the need for high-speed data transmission and signal integrity, the demands placed on military PCBs are unparalleled. Customers in the military sector often face the following challenges:

1. Size and weight constraints: Military equipment needs to be lightweight and compact, requiring PCBs to be flexible and adaptable to fit into tight spaces within the equipment.

2. Harsh environmental conditions: Military equipment operates in extreme environments, including high temperatures, moisture, and exposure to chemicals and solvents, requiring PCBs that can withstand these conditions without compromising performance.

3. Signal integrity and high-speed data transmission: Military applications often require high-speed data transmission and signal integrity, requiring PCBs to have precise impedance control and minimal signal loss.

4. Capel’s custom solutions: bringing technological innovation into the military field

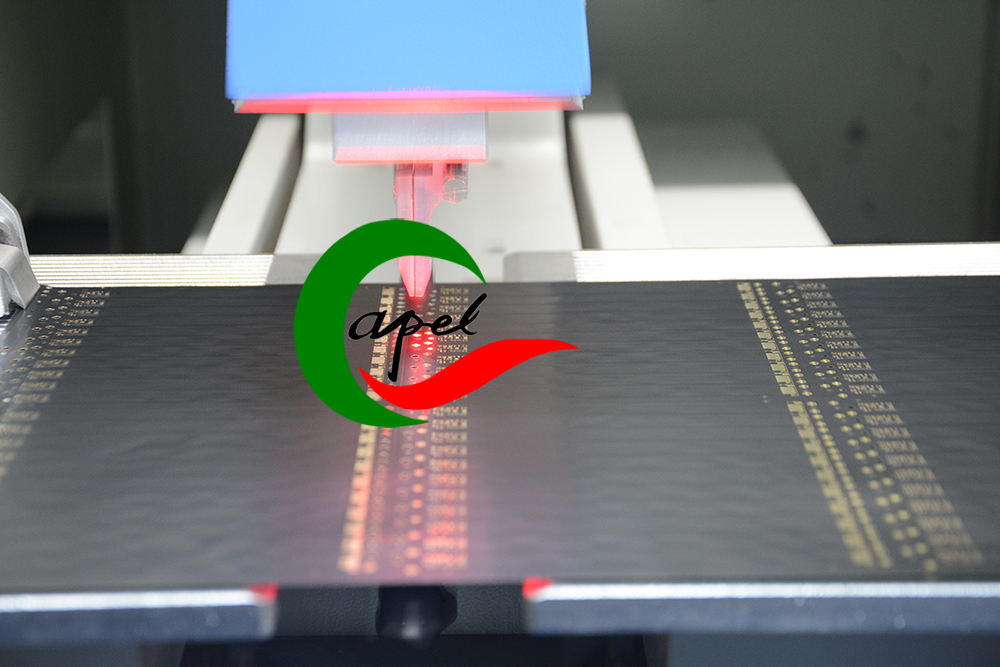

Capel has been at the forefront of technology innovation in military and defense FPC manufacturing, providing customized solutions to address the unique challenges faced by customers in the military sector. Through a combination of advanced materials, innovative design techniques and rigorous testing, Capel’s military flexible PCBs set new standards for reliability, performance and durability.

5. Defense Flexible PCB Case Study Analysis: Solving Industry-Specific Challenges

Let’s take a closer look at some case studies where Capel’s custom solutions have successfully solved industry-specific challenges for military customers:

Case study 1: Miniaturization of electronic systems

A leading defense contractor presented Capel with the challenge of miniaturizing electronic systems for a new generation of unmanned aerial vehicles (UAVs). The customer required a PCB that could fit into the tight space within the drone while also being able to withstand the vibration and shock experienced during flight. Capel’s custom-designed flexible PCB not only meets size and weight constraints, but also provides the necessary durability to withstand harsh operating conditions, ensuring the reliability of the drone’s electronic system.

Case Study 2: Signal Integrity in Radar Systems

A military research organization sought a solution to improve the signal integrity and high-speed data transmission of its radar system. Capel’s engineering team developed a custom flexible PCB with precise impedance control and low signal loss, resulting in improved radar system performance and accuracy. The ability of the PCB to conform to curved surfaces within the radar device also contributes to overall system efficiency.

6. Capel’s military flexible PCB product information:

Capel’s military flexible PCBs are designed to meet the stringent requirements of the defense sector and offer the following benefits:

1. Flexibility and Consistency: Capel’s flexible PCBs can bend, twist and conform to irregular shapes, making them ideal for applications with limited space and irregular form factors.

2. Durability and reliability: The use of advanced materials and manufacturing processes ensures that Capel’s military flexible PCBs can withstand harsh environmental conditions, including extreme temperatures, moisture and chemical exposure, without compromising performance.

3. High-speed data transmission: Capel’s flexible PCB features precise impedance control and low signal loss, enabling high-speed data transmission and signal integrity, which is critical for military applications requiring real-time communication and data processing.

4. Custom Solutions: Capel’s engineering team works closely with customers to develop custom solutions that fit their specific requirements, ensuring the PCB meets the unique challenges of military applications.

High-Precision Military Flexible PCB Solutions by Capel Manufacturer

6. Conclusion: Promote military PCB technology progress

In summary, developments in military PCB and flexible PCB technology have transformed the defense sector, enabling the development of advanced electronic systems that meet the stringent requirements of military applications. Capel’s custom solutions have played a key role in solving military customers’ industry-specific challenges, bringing technological innovation to the field and setting new standards for reliability, performance and durability of military flexible PCBs. As a flexible PCB engineer with extensive experience in the military and defense FPC manufacturing industry, I have seen firsthand the impact of Capel’s custom solutions, and I believe their continued innovation will drive further advancements in military PCB technology.

Post time: Mar-12-2024

Back