Introduce

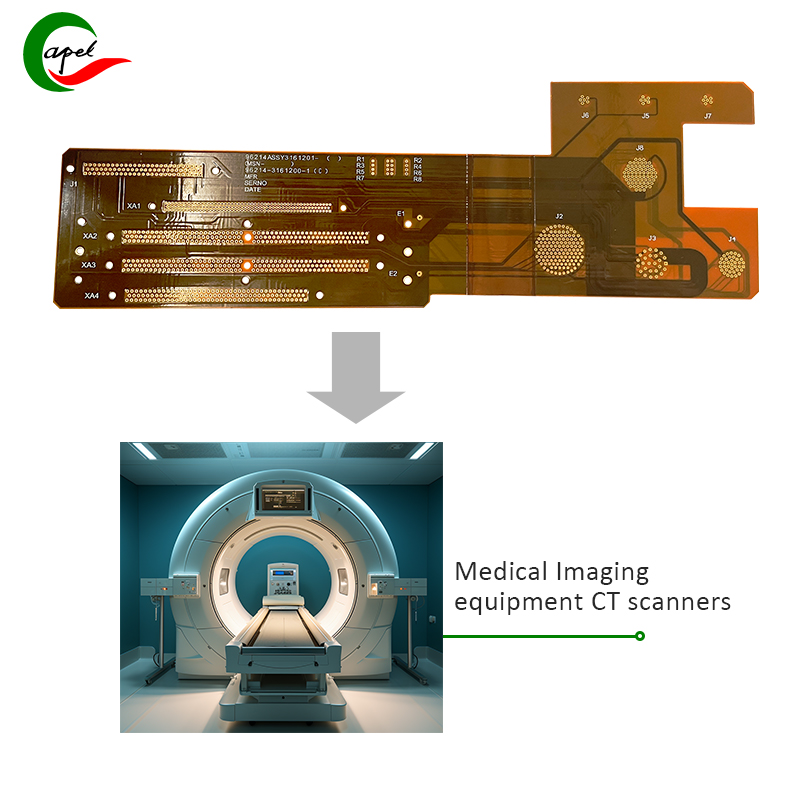

In the ever-evolving world of healthcare, technological advancements play a key role in improving patient care and outcomes. Medical printed circuit board (PCB) prototyping is a critical component of the development and manufacturing process for a variety of medical devices, ensuring the production of high-quality, reliable devices that meet the healthcare industry’s rigorous standards.

Medical circuit boards are the foundation of electronic components in medical equipment, enabling efficient transmission of important data and seamless operation of life-saving equipment. The importance of high-quality, reliable medical PCBs cannot be overstated as they form the backbone of advanced medical equipment used in hospitals, clinics and other medical facilities. By utilizing precise design and manufacturing processes, medical PCB prototyping plays a vital role in the advancement of modern healthcare technology.

Benefits of Medical PCB Prototyping

Using PCB prototyping in medical devices offers numerous benefits that directly impact the functionality, reliability, and efficiency of the medical device. PCB prototyping can create custom, application-specific circuits to meet the unique requirements of medical devices. This level of customization ensures medical devices operate at peak performance, delivering accurate results and precise data transfer.

In addition to customization, high-quality PCBs can help increase the reliability and longevity of medical equipment, reducing the risk of malfunctions and errors that could compromise patient safety. Seamless integration of PCB prototyping with medical devices helps improve functionality, giving healthcare professionals a reliable tool to provide optimal patient care.

Additionally, the efficiency gains achieved through the use of high-quality PCBs result in cost-effective solutions for medical device manufacturers, ultimately resulting in more accessible and affordable medical devices for providers and patients. By optimizing the performance of medical devices, PCB prototyping helps increase operational efficiency and improve patient outcomes.

Factors to consider in medical PCB prototyping

Given the critical nature of medical PCB applications in healthcare technology, precision and accuracy are critical to the design and manufacturing of medical PCBs. The ability to produce complex, high-density circuits to precise specifications is fundamental to the reliable operation of medical equipment and devices. Factors such as signal integrity, thermal management and electromagnetic compatibility must be carefully considered during the PCB prototyping process to ensure optimal performance and safety.

Additionally, adhering to strict safety and regulatory standards within the healthcare industry is critical for medical circuit board prototyping. Manufacturing processes must comply with industry-specific regulations and quality standards to ensure the safety and effectiveness of medical devices. Adhering to strict guidelines ensures that medical devices meet the highest quality and safety requirements, protecting the safety of patients and healthcare providers.

Choosing the Right PCB Manufacturer for Medical Devices

Choosing a reputable PCB manufacturer is a critical decision for medical device developers and manufacturers. The criteria for selecting the right partner in medical PCB prototyping go beyond traditional considerations to include specific expertise and experience in the healthcare industry. Manufacturers who specialize in medical PCBs must have a deep understanding of the unique needs and requirements of medical devices, as well as the ability to navigate and comply with industry-specific regulations.

The importance of quality assurance in medical printed circuit board prototyping cannot be overstated. Reliable manufacturers will implement strict quality control processes throughout the prototyping and production stages to ensure that each medical PCB meets the highest standards of performance, reliability, and safety. By partnering with an experienced manufacturer with a proven track record in medical PCB prototyping, healthcare device developers can reduce risk and achieve optimal results for their products.

Medical PCB Prototype Success Case Studies

Real-life examples demonstrate the tangible impact of medical PCB prototyping on the healthcare industry. Case studies demonstrating successful applications of PCB prototyping provide valuable insights into the transformative power of advanced circuits in medical devices. These case studies highlight specific challenges and corresponding solutions achieved through precise PCB design and manufacturing, illustrating the critical role of high-quality PCBs in enhancing healthcare technology.

One of the case studies involves the development of a state-of-the-art portable diagnostic device for rapid blood analysis. By leveraging advanced microelectronics and precision PCB prototyping, the device is engineered to deliver accurate results in minutes, revolutionizing point-of-care testing in clinical settings. The successful integration of high-quality PCBs in this medical device demonstrates the ability of advanced prototyping processes to drive innovation and improve patient care.

Another case study focuses on enhancing a cardiac monitoring device by implementing a specialized PCB design. By overcoming challenges related to signal integrity and electromagnetic interference, the development team has made significant advances in the reliability and accuracy of the monitoring device, providing healthcare professionals with more reliable data for critical patient assessments. These success stories highlight the transformative potential of medical PCB prototyping to drive advancements in the healthcare field.

Future trends in medical PCB prototyping

The future of medical PCB prototyping is marked by continued technological advancements and innovative solutions that promise to reshape the healthcare industry. Emerging technologies such as flexible and wearable electronics have the potential to revolutionize the design and functionality of medical devices. Integrating flexible PCBs into wearable healthcare solutions enables unprecedented levels of patient monitoring and data collection, paving the way for new possibilities in personalized healthcare.

In addition, developments in miniaturized PCB technology continue to drive the development of compact, high-performance medical devices. The shrinking form factors of electronic components, driven by advanced PCB prototyping, enable the creation of portable, non-invasive medical devices that give patients greater autonomy and mobility. These advancements not only improve patient comfort but also expand the scope of medical services in different settings.

Advances in medical PCB prototyping also intersect with the rise of artificial intelligence and machine learning in healthcare. The integration of smart circuits in medical devices enables real-time data analysis, predictive diagnostics and adaptive functions to improve the accuracy and efficiency of patient care. As these technology trends converge, the future of medical PCB prototyping promises unprecedented innovation and transformative impact on healthcare delivery.

medical pcb fabrication process

In summary

High-quality, reliable medical PCB prototyping is critical to shaping the future of healthcare technology. From its role in optimizing medical device performance and efficiency to its impact on patient care and outcomes, PCB prototyping has been a cornerstone of advancement in the healthcare industry. It is critical for healthcare technology developers to recognize the importance of working with reputable medical device PCB manufacturers who have the expertise, experience, and commitment to quality assurance needed to advance medical PCB prototyping .

Overall, the importance of medical PCB prototyping lies in its ability to drive innovation, enhance patient care, and propel the healthcare industry into a future marked by advanced technology and superior quality. By prioritizing accuracy, compliance and partnering with experienced manufacturers, medical device developers can harness the full potential of PCB prototyping to revolutionize healthcare delivery and improve patient well-being around the world.

Post time: Jan-05-2024

Back