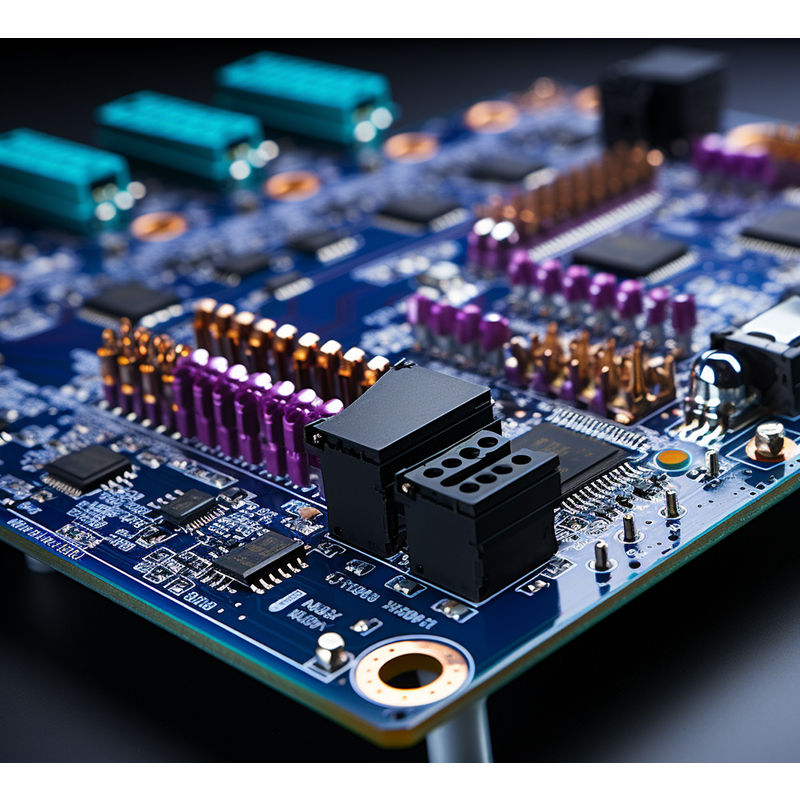

Introduce:

Building a prototype circuit board is an important step in the product development process. It allows engineers, designers and manufacturers to test and refine their ideas before proceeding to production. However, there are some common mistakes that can hinder the success of your prototype board. In this blog post, we’ll discuss these mistakes and provide tips on how to avoid them to ensure a smooth and successful PCB prototyping process.

1. Neglect of proper planning and design

One of the most serious mistakes when building a prototype circuit board is neglecting proper planning and design. Rushing into the prototyping phase without a well-thought-out plan can result in wasted time, effort, and resources. Before you start building, it’s critical to create a clear schematic, define the component layout, and lay out a comprehensive circuit design.

To avoid this mistake, take the time to plan and design your prototyping board thoroughly. This includes understanding the goals of the circuit, selecting appropriate components, and creating a detailed schematic. Using PCB design software can also help streamline the planning process and avoid potential design flaws.

2. The circuit design is too complex

Overcomplicating circuit design is another common mistake that can lead to prototype board failure. While it’s natural to want to include all features and functionality in your initial design, doing so can make the board complex and difficult to assemble. This increases the risk of errors and reduces the chance of prototype success.

To avoid overcomplicating your circuit design, focus on the main goals of your prototype. Start with a minimalist approach and gradually increase complexity if necessary. Simplicity not only improves the chances of a successful build, it also saves time and reduces costs.

3. Not considering thermal management

Thermal management is often overlooked when building prototype circuit boards, leading to overheating and device failure. Inadequate consideration of cooling can lead to overall performance degradation and, in some cases, irreversible damage to components.

To avoid this mistake, consider factors such as component placement, heat sinks, and airflow to ensure proper thermal management. Proper distribution of heat-generating components and the use of thermal vias or pads can help dissipate heat efficiently and prevent any potential problems.

4. Ignoring testing and validation

Another major mistake is neglecting to thoroughly test and validate the prototype board. Skipping this critical step increases the risk of overlooking design flaws, functionality issues, and compatibility issues. Comprehensive testing not only guarantees the functionality of the board, but also its stability under different conditions.

To avoid this mistake, incorporate adequate testing and validation procedures throughout the prototyping phase. Perform functional testing, signal integrity testing, and environmental testing to ensure prototype reliability and durability. This step helps identify potential problems early and allows necessary modifications to be made before entering production.

5. Ignore design for manufacturability

Design for manufacturability (DFM) is often overlooked during the prototyping stage, leading to difficulties and increased costs during volume production. Ignoring manufacturing requirements and constraints can result in design flaws, unfavorable material selection, and inefficient assembly processes.

To avoid this mistake, familiarize yourself with DFM principles and guidelines. Optimize the design for ease of manufacturing, select off-the-shelf components, and consider the manufacturing and assembly process throughout the prototyping phase. Engaging with manufacturers early on can also provide valuable insights and potential cost-saving recommendations.

In conclusion:

Building prototype circuit boards is an integral part of the product development process. You can ensure a successful prototyping process by avoiding common mistakes such as neglecting proper planning, overcomplicating designs, neglecting thermal management, skipping testing, and neglecting to design for manufacturability. Taking the time to plan, design, test, and optimize prototype boards will make the transition to production more efficient and cost-effective. Remember, a well-executed prototype board is the stepping stone to a successful, market-ready product.

Post time: Oct-25-2023

Back