Rigid-flex boards (printed circuit boards) have revolutionized the way electronic devices are designed and manufactured. Their ability to combine the advantages of rigid and flexible circuits has made them very popular in various industries. However, like any technology, rigid-flex has its limitations in terms of size.

One of the most significant advantages of rigid-flex panels is their ability to fold or bend to fit into compact and irregularly shaped spaces. This flexibility enables designers to integrate PCBs into space-constrained devices such as smartphones, wearables, or medical implants. While this flexibility provides a lot of freedom in design, it does come with some size limitations.

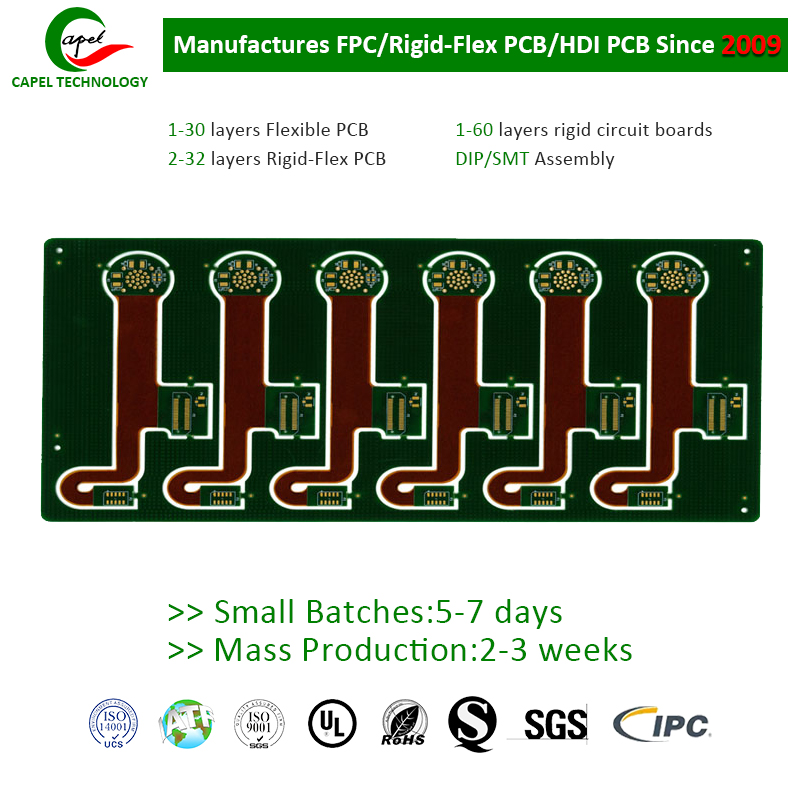

The size of a rigid-flex PCB is determined by a variety of factors, including manufacturing process, number of layers, and component density. The manufacturing process of rigid-flex PCBs involves joining together rigid and flexible substrates, which include multiple layers of copper, insulating materials and adhesives. Each additional layer increases the complexity and cost of the manufacturing process.

As the number of layers increases, the overall thickness of the PCB increases, limiting the minimum size achievable. On the other hand, reducing the number of layers helps reduce overall thickness but may affect the functionality or complexity of the design.

Component density also plays a critical role in determining the size limitations of rigid-flex PCBs. Higher component density requires more traces, vias, and pad space, thereby increasing the overall PCB size. Increasing PCB size is not always an option, especially for small electronic devices where space is at a premium.

Another factor limiting the size of rigid-flex boards is the availability of manufacturing equipment. PCB manufacturers have certain limitations on the maximum size they can manufacture. Dimensions may vary by manufacturer, but typically range from a few inches to several feet, depending on device capabilities. Larger PCB sizes require specialized equipment and may incur higher manufacturing costs.

Technical limitations are also a consideration when it comes to sizing rigid-flex PCBs. Advances in technology have made electronic components smaller and more compact. However, these components may have their own limitations in terms of dense packaging and heat dissipation. Reducing rigid-flex PCB dimensions too much can cause thermal management issues and affect the overall reliability and performance of the electronic device.

While there are limits to the size of rigid-flex boards, these limits will continue to be pushed as technology advances. Size limitations are gradually being overcome as manufacturing processes become more sophisticated and specialized equipment becomes more readily available. In addition, advances in component miniaturization and thermal management technology have made it possible to implement smaller, more powerful electronic devices using rigid-flex PCB boards.

Rigid-flex PCB combines the advantages of rigid and flexible circuits, providing tremendous design flexibility. However, these PCBs do have limitations in terms of size. Factors such as manufacturing processes, component density, equipment capabilities and technology constraints play a critical role in determining the maximum size achievable. Despite these limitations, continued advances in technology and manufacturing processes are pushing the limits of rigid-flex printed circuit boards.

Post time: Sep-16-2023

Back