Introduce:

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry by enabling compact and flexible designs. They offer many advantages over their rigid counterparts, such as superior thermal management, reduced weight and size, and improved reliability. However, when it comes to 2-layer flexible PCB stack-ups, the inclusion of stiffeners becomes critical. In this blog, we’ll take a closer look at why 2-layer flexible PCB stackups require stiffeners and discuss their importance in ensuring optimal performance and longevity.

Learn about flexible PCB stackup:

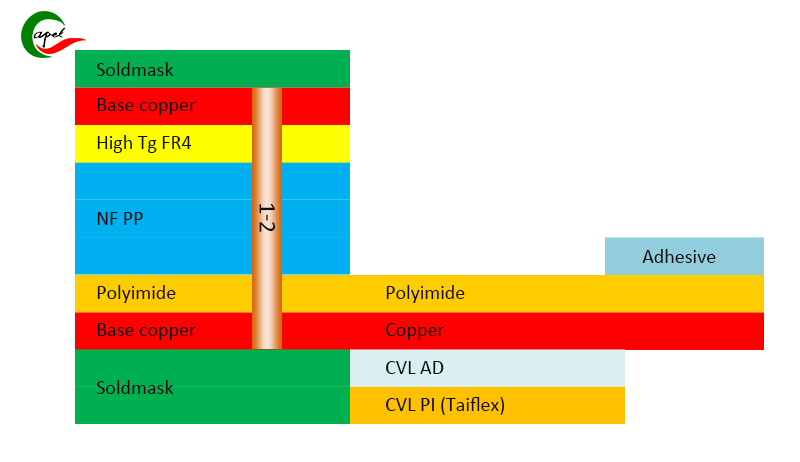

Before we delve into the importance of stiffeners, we first need to have a clear understanding of what flexible PCB layup is. Flexible PCB layup refers to a specific arrangement of multiple layers in a flexible circuit board. In a 2-layer stackup, a flexible PCB consists of two copper layers separated by a flexible insulating material (usually polyimide).

Why does a 2-layer flexible PCB stackup need stiffeners?

1. Mechanical support:

One of the main reasons why stiffeners are needed in a 2-layer flexible PCB stackup is to provide mechanical support. Unlike rigid PCBs, flexible PCBs lack inherent rigidity. Adding stiffeners helps strengthen the structure and prevents the PCB from bending or warping during handling or assembly. This becomes especially important when flexible PCBs are frequently bent or folded.

2. Enhance stability:

Ribs play a vital role in enhancing the stability of the 2-layer flexible PCB stack-up. By providing rigidity to the PCB, they help minimize the possibility of vibration-induced problems, such as resonance, that can negatively impact the overall performance and reliability of the circuit. In addition, stiffeners allow for better alignment and registration during assembly, ensuring precise positioning of components and interconnect traces.

3. Component support:

Another important reason why 2-layer flex PCB stackups require stiffeners is to provide support for components. Many electronic devices require surface mount technology (SMT) components to be mounted on flexible PCBs. The presence of stiffeners helps disperse the mechanical stresses exerted during soldering, preventing damage to precision components and ensuring their correct alignment on the flexible substrate.

4. Protection from environmental factors:

Flexible PCBs are often used in applications that are exposed to harsh environmental conditions, such as extreme temperatures, humidity, or chemical exposure. The ribs act as a protective barrier, protecting delicate circuits from potential damage caused by these environmental factors. Additionally, they help improve the flexible PCB’s overall resistance to mechanical stress and prevent moisture ingress, thereby increasing its longevity and reliability.

5. Routing and Signal Integrity:

In a 2-layer flex PCB stackup, signal and power traces usually run on the inner layer of the flex board. The ribs are present to maintain proper spacing and prevent electrical interference between internal copper layers. In addition, stiffeners protect sensitive high-speed signal traces from crosstalk and signal attenuation, ensuring controlled impedance and ultimately maintaining the circuit’s signal integrity.

In conclusion:

In summary, stiffeners are an important component in a 2-layer flexible PCB stack-up as they play a role in providing mechanical support, enhancing stability, providing component support, and protecting against environmental factors. They protect precision circuits, maintain optimal signal integrity, and allow successful assembly and reliable operation in a variety of applications. By incorporating stiffeners into flexible PCB designs, engineers can ensure the robustness and longevity of their electronic devices while enjoying the benefits of flexible circuits.

Post time: Nov-17-2023

Back