In the rapidly evolving field of healthcare technology, the role of printed circuit boards (PCBs) is becoming increasingly important. Among various types of PCBs, rigid-flex medical PCBs have become key components with numerous advantages that help improve the efficiency, safety, and reliability of medical equipment. This article provides an in-depth look at the benefits, applications, design considerations and regulatory compliance associated with rigid-flex medical PCBs in the healthcare industry.

1. Introduction

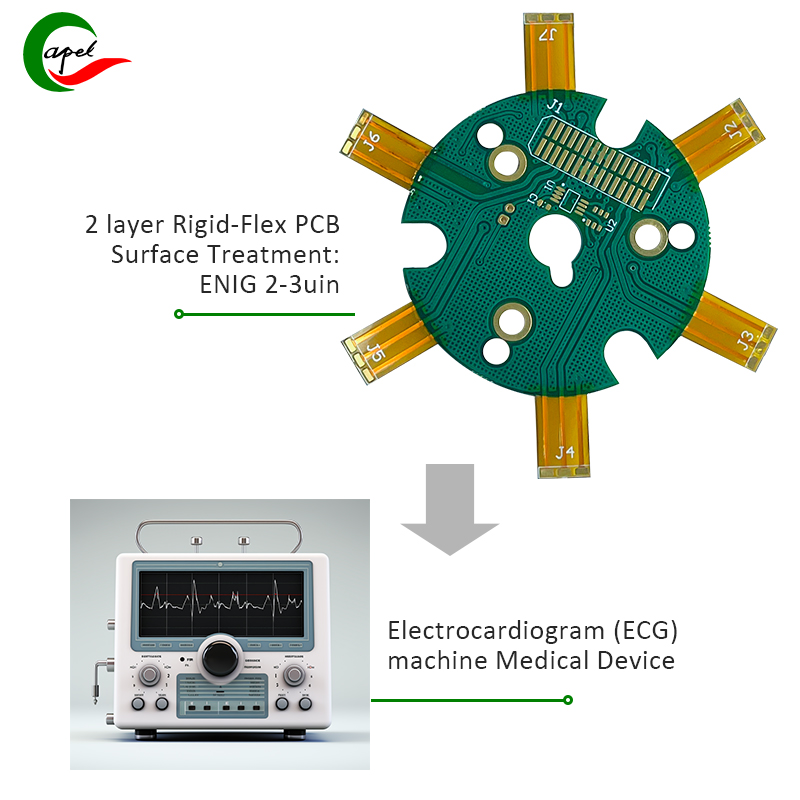

Printed circuit boards (PCBs) are important components in medical devices, providing a platform for the assembly and interconnection of electronic components. In particular, rigid-flexible medical PCBs combine the advantages of rigid and flexible PCBs, providing unique design possibilities for medical equipment.

In the field of medical devices, PCBs play a key role in enabling the functionality of various electronic systems, such as diagnostic equipment, patient monitoring equipment, implantable medical devices, and medical imaging equipment. The integration of rigid and flexible PCB substrates in medical devices has led to significant advancements, improving the performance, reliability and functionality of these devices.

2. Advantages of rigid-flexible medical PCB

Flexible and space-saving design

Rigid-flex medical PCBs provide unparalleled design flexibility to achieve complex and compact form factors that conform to the shape and size requirements of medical devices. The flexibility of this design not only helps save space but also creates innovative and ergonomic medical devices that are comfortable for patients and healthcare professionals.

Improve reliability and durability

Seamless integration of rigid and flexible substrates in medical printed circuit board increases reliability and durability. Eliminating traditional interconnects and connectors reduces the risk of mechanical failure because soldered connections create fewer points of failure. This increased reliability is critical in medical applications, where consistent and accurate performance of equipment is critical to patient care and safety.

Improve signal integrity and reduce electromagnetic interference

Rigid-flex medical PCBs provide superior signal integrity because the flexible substrate reduces impedance mismatch and signal loss. Additionally, the reduced number of interconnects minimizes electromagnetic interference, ensuring the accuracy of electronic signals in sensitive medical applications such as diagnostic equipment and patient monitoring equipment.

Cost-effective and reduces assembly time

Simplified manufacturing processes for rigid-flex medical PCBs can save costs and reduce assembly time. By consolidating multiple PCBs into a rigid-flex design, manufacturers can minimize material and assembly costs while streamlining the assembly process, resulting in overall cost savings without compromising quality or performance.

3. Application of rigid-flexible medical PCB

Rigid-flex medical PCB is widely used in various medical equipment, including but not limited to:

Implantable medical devices

Rigid-flex PCBs are integral to the design and functionality of implantable medical devices such as pacemakers, defibrillators, neurostimulators, and implantable drug delivery systems. The flexible nature of these PCBs allows them to conform to the contours of the human body, allowing the development of minimally invasive and highly reliable implantable devices.

medical imaging equipment

In medical imaging equipment such as MRI machines, CT scanners and ultrasound equipment, rigid-flex medical circuit boards play a vital role in integrating complex electronic components while providing the necessary flexibility to accommodate the mechanical constraints of these devices. This integration enables imaging systems to operate seamlessly, helping to achieve accurate diagnostic results and patient care.

patient monitoring equipment

Rigid-flex medical PCBs are used in patient monitoring devices, including wearables, EKG monitors, pulse oximeters, and continuous glucose monitoring systems. The flexibility and reliability of these PCBs are critical to the development of comfortable and accurate monitoring devices that can provide healthcare professionals with real-time data to help improve patient care and treatment.

diagnostic equipment

Instruments used for medical diagnostics, such as blood analyzers, DNA sequencers, and point-of-care testing devices, benefit from the integration of rigid-flex medical PCBs as they facilitate the development of portable, reliable, and accurate diagnostic devices. These PCBs facilitate seamless integration of advanced electronic components, helping to improve the accuracy and efficiency of diagnostic procedures.

4. Things to note when designing rigid-flexible medical PCB

When designing rigid-flex medical PCBs for healthcare applications, several key factors must be considered:

Material selection

Careful material selection is critical to ensuring the reliability and performance of rigid-flex medical PCBs. The selection of substrates, adhesives, and conductive materials should be based on factors such as mechanical flexibility, thermal properties, biocompatibility, and resistance to sterilization processes, especially for medical devices intended for implantation.

Component placement

The placement of electronic components on rigid-flex medical PCBs plays an important role in the functionality, reliability, and manufacturability of the device. Proper component placement involves layout that optimizes signal integrity, minimizes thermal issues, and accommodates the mechanical limitations of the medical device while ensuring ease of assembly and maintenance.

Manufacturing and testing process

The manufacturing and testing process of rigid-flex medical PCBs requires specialized expertise and equipment to ensure the quality, reliability and regulatory compliance of the final product. Thorough testing, including electrical testing, thermal cycling, and reliability testing, is critical to verify the performance and safety of medical PCBs before integrating them into medical devices.

5. Regulatory Compliance and Quality Standards

When developing and producing rigid-flex medical PCBs for the healthcare industry, meeting regulatory requirements and quality standards is critical. Compliance with standards set by the U.S. Food and Drug Administration (FDA) and the International Organization for Standardization (ISO) is critical to ensuring the reliability and safety of medical PCBs. Compliance with these standards helps reduce risks associated with the use of medical devices and increases the confidence of healthcare professionals, regulatory agencies and patients in the performance and safety of medical PCBs.

Rigid-Flex PCB Circuit Board Manufacturing Process

6 Conclusion

The advantages of rigid-flexible medical PCBs significantly enhance the functionality of medical devices and help provide advanced healthcare solutions. These PCBs enable flexible and space-saving designs, coupled with improved reliability, signal integrity and cost-effectiveness, making them key enablers of innovation in the healthcare industry. Looking ahead, continued advancement and innovation in medical device technology, driven in part by the development of rigid-flexible medical PCBs, is expected to further improve patient care, treatment outcomes and the development of next-generation medical devices. As healthcare technology continues to advance, the role of rigid-flexible medical PCBs will undoubtedly remain an integral part of driving innovation in medical devices and providing quality healthcare services.

Post time: Jan-05-2024

Back