Explore the versatility and functionality of 1-30 layer flexible PCBs fabrication with Capel Manufacturer Manufacturing special process, a leading expert in flexible PCB manufacturing. From understanding the benefits of flexible PCBs to delving into technical specifications and layer options, this comprehensive article is for electronics design engineers and product developers Provided valuable insights.

1. Introduction to Flexible PCB and Capel Manufacturing

A. Brief Overview of Flexible PCB

Flexible PCB, also known as flex circuit, is a printed circuit board that provides flexibility and versatility in electronic applications. They can bend, twist and fold to fit into tight spaces, making them ideal for space-constrained products.

B. Introduction to Capel Manufacturing and its expertise in flexible PCB production

With 16 years of flexible PCB manufacturing experience, Capel Manufacturing has become a leading manufacturer of high-quality flexible PCBs. The company’s expertise lies in the production of flexible printed circuit boards with different layer options to meet the diverse needs of its customers.

Learn about the advantages of flexible PCBs

1. Definition and use of flexible PCB

Flexible PCBs are used in a wide range of applications, including consumer electronics, automotive systems, medical equipment and aerospace technology. Their flexibility allows for efficient connection routing and reduces the need for bulky wiring harnesses.

B. Advantages of using flexible PCB over rigid PCB

Flexible PCBs offer several advantages over rigid PCBs, including weight and space savings, improved reliability, and enhanced thermal performance. They can also create complex three-dimensional designs, making them suitable for innovative product designs.

C. The importance of flexible PCB layers

The number of layers in a flexible PCB affects its performance and functionality. Different applications require different layer options to accommodate the complexity of the circuit design and the specific requirements of the end product.

Explore layer options in flexible PCBs

A. Explore the layer range of flexible PCB

Capel Manufacturing offers a variety of layer options for flexible PCBs, from single-sided to multi-layer configurations. This flexibility allows customers to choose the best tier configuration based on their application needs.

B. Capel Manufacturing’s ability to produce 1-30 layer flexible PCB prototypes and manufacturing

Capel Manufacturing has advanced production capabilities capable of manufacturing up to 30-layer flexible PCB prototypes and high-volume production. This broad range of layers meets the needs of different industries and applications.

C. What the different tier options mean for specific applications

The choice of layer configuration affects the electrical performance, signal integrity and overall functionality of the flexible PCB. Capel Manufacturing has expertise in guiding customers to select the most appropriate ply options for their specific applications, ensuring optimal performance and reliability.

Capel Manufacturing’s Product Line Overview

A. Capel Flexible PCB Product Line Overview

Capel Manufacturing offers a full line of flexible PCB products including single-sided, double-sided, single-layer, dual-layer and multi-layer configurations. Each flexible circuit board is designed to meet the highest quality standards and performance requirements.

B. Detailed description of single-sided, double-sided, single-layer, double-layer and multi-layer flexible PCB

Single- and double-sided flexible PCBs are suitable for applications with simpler circuit designs, while single-, double- and multi-layer configurations accommodate more complex circuit and interconnect requirements. Capel Manufacturing’s diverse product lines ensure customers can find the ideal solution for their specific needs.

C. Highlight the unique features of Capel flexible PCB, including HDI flexible PCB and special processes

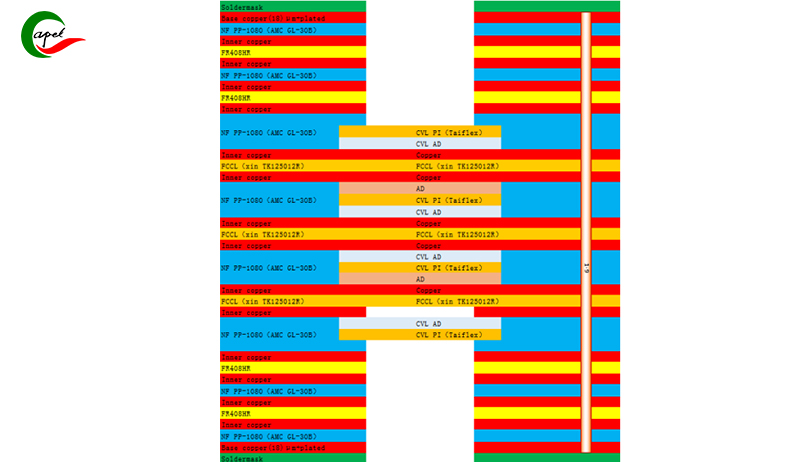

multilayer flex pcb special process

Capel Manufacturing specializes in high-density interconnect (HDI) flexible PCBs that provide enhanced wiring density and signal integrity. In addition, the company uses special processes such as impedance control and controlled dielectric materials to meet the most demanding technical specifications.

Technical specifications and precision manufacturing

A. Discuss technical aspects of Capel flexible PCB such as line width and spacing

Capel Manufacturing’s flexible PCBs follow precise technical specifications, including line width, spacing and impedance control. These key parameters ensure reliable performance of flexible PCBs under various operating conditions.

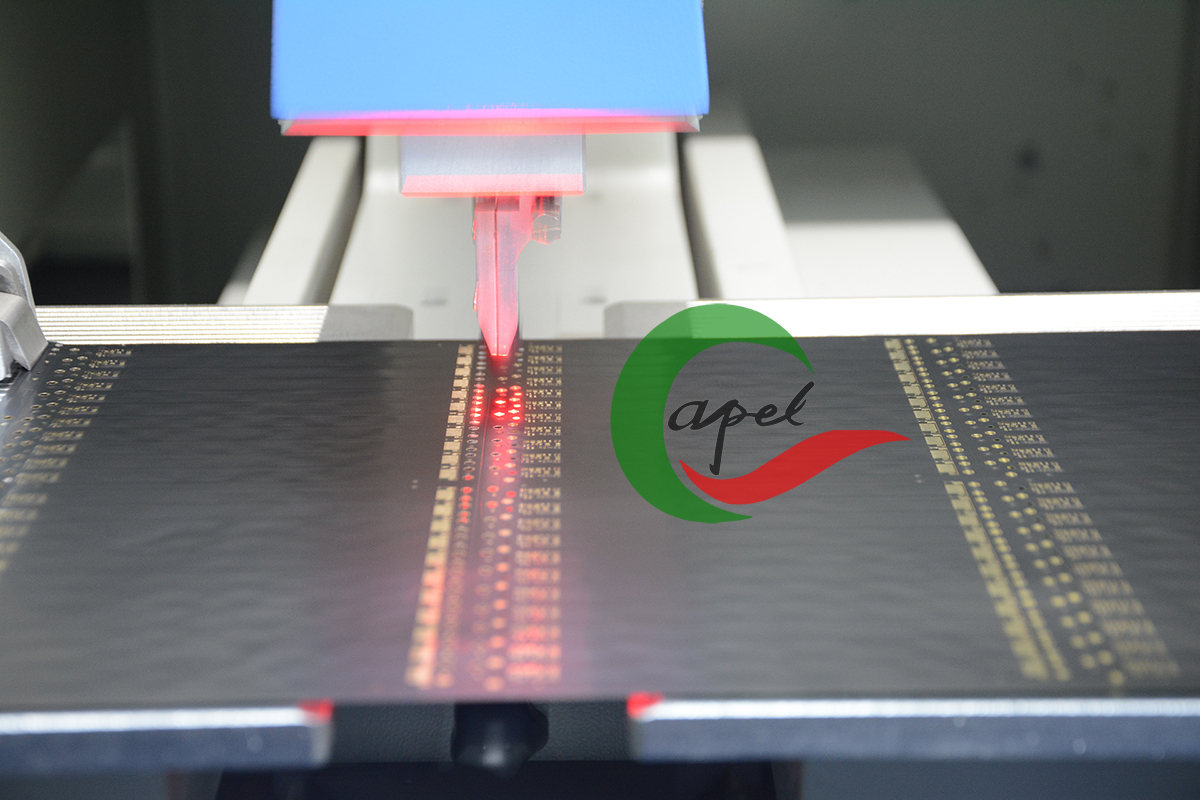

B. Emphasis on the precision and quality of Capel’s flexible PCB manufacturing process

Capel’s manufacturing process is characterized by strict quality control measures and advanced production technology. This allows flexible PCBs to exhibit superior accuracy, reliability and consistency across all layers and configurations.

C. Meeting customer specific requirements and available customization options

Capel Manufacturing offers customization options to tailor flexible PCBs to each customer’s unique requirements. Whether it’s a specific material selection, surface finish or special design considerations, the company works closely with customers to provide customized solutions.

Conclusion: Realizing the potential of flexible PCBs

A. Summarize the versatility and functionality of flexible PCB

Flexible PCBs offer unparalleled versatility and functionality, enabling innovative product designs and reliable electronic interconnections. Their ability to adapt to complex form factors and dynamic environments makes them indispensable in modern electronic applications.

B. Highlight Capel Manufacturing’s expertise in producing high-quality flexible PCBs with multi-layer options

Capel Manufacturing’s 16 years of experience and technical prowess have made the company a trusted partner in the production of high-quality flexible PCBs. A wide range of layer options and advanced manufacturing capabilities underscore the company’s commitment to meeting the industry’s ever-changing needs.

C. Readers are encouraged to explore the possibilities of flexible PCBs for their specific applications

As the demand for flexible PCBs continues to grow across industries, we encourage readers to explore the potential of flexible PCBs in their specific applications. Capel Manufacturing is ready to work with customers to turn their innovative ideas into reality with custom flexible PCB solutions.

Overall, Capel Manufacturing’s expertise in flexible PCB production, coupled with its diverse product lines and technical capabilities, makes the company a leading provider of high-quality flexible PCB solutions for a variety of applications.

Post time: Apr-06-2024

Back