This article introduces 4-layer flexible PCB technology and its innovative application in intelligent sweeping robots. Detailed interpretation of 4 layer flexible pcb stack-up structure, circuit layout, various types, important industry applications and specific technological innovations, including line width, line spacing, board thickness, minimum aperture, minimum aperture, copper thickness,surface treatment,flame retardant,resistance welding and stiffness., etc. These technological innovations have brought a wealth of possibilities for the design and functional improvement of intelligent sweeping robots, and have significantly improved the performance, reliability, flexibility and agility of sweeping robots systems

What kind of technology is 4-layer flexible PCB?

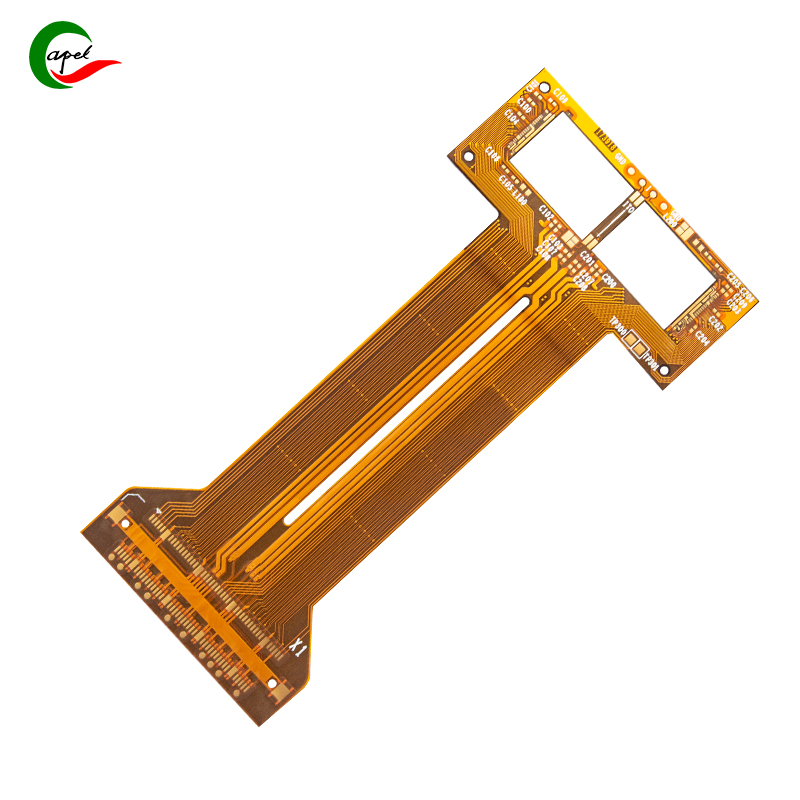

4-layer flexible PCB is a special circuit board technology that consists of four layers that are stacked together in a scroll-like manner. The circuit board is very flexible and can be bent and twisted to adapt to different shapes of devices. For example, in some curved electronic devices, traditional hard circuit boards cannot be used, and 4-layer flexible PCBs can easily meet the needs. It is designed so that electricity can flow between the different layers, while the insulating layer isolates the circuit and avoids short circuits. This technology has wide applications in various fields, such as smartphones, medical devices and automotive electronics. By using 4-layer flexible PCB, electronic devices can be more flexible, lightweight, and adaptable to various complex environments.

What is the laminated structure of a 4-layer flexible PCB?

A 4-layer flexible PCB is composed of four flexible sheets stacked on top of each other. First is the bottom substrate, then the inner copper foil, then the inner substrate, and finally the surface copper foil. This structure allows electronic components to be arranged on a soft substrate, while circuit connections are realized through the inner copper foil, and the surface copper foil is used to transmit signals and ground. This structural design allows the circuit board to bend and twist, making it ideal for use in devices that require flexible circuits. Flexible PCBs are widely used in mobile phones, tablets, medical equipment and other fields, making these devices more portable and flexible, while also improving the stability and reliability of circuits.

How to lay out the circuit layers of a 4-layer flexible PCB?

The circuit layer layout of the 4-layer flex PCB includes the bottom substrate, inner copper foil, inner substrate and surface copper foil. On the bottom substrate, the inner copper foil and the inner substrate are stacked in sequence, and the surface copper foil covers the inner substrate. This structure can support circuit connections and signal transmission, while making the PCB flexible and able to bend and twist. Electronic components can be mounted on the flexible substrate, while inner layers of copper foil are used to connect circuits between the different layers. This layout is suitable for electronic devices that require flexibility and miniaturization, such as smart bracelets, smart wearable devices, etc. The design of flexible PCB can improve the performance and reliability of equipment and is suitable for products with limited space and special shape requirements.

What types of 4-layer flexible pcb can there be?

4-layer flexible circuit board can have different types such as single-sided flexible PCB, double-sided flexible PCB and multi-layer flexible PCB. Single-sided flexible PCB is the most basic type. Single-sided copper cladding, that is, copper foil cladding on one side, is suitable for simple circuit design and lower cost requirements. Double-sided flexible PCB is double-sided copper-clad, both sides are covered with copper foil, and is suitable for complex circuits and signal transmission. Multi-layer flexible PCB has more copper foil layers and insulation layers. In addition, there are double-sided copper cladding + blind buried holes. This type adds blind hole design on the basis of double-sided copper cladding for connection. Internal and external layers of circuitry. The last type is double-sided copper + drilling. This type adds a through-hole design based on double-sided copper, which can be used to connect circuits on all layers. These types of 4-layer flexible PCBs have their own characteristics and scope of application, and the appropriate type can be selected according to specific circuit requirements.

What are the main applications of 4-layer flexible PCB in major industries around the world?

Consumer electronics products: such as smartphones, tablets, wearable devices, etc. Flexible PCBs can adapt to small spaces and curved designs, so they are widely used in these products.

Medical equipment: Medical equipment requires reliable electrical connections and sometimes requires a design that can bend. 4-layer flexible PCBs are widely used in medical equipment.

Automotive electronic systems: In modern automobiles, flexible PCBs are used for in-vehicle electronic systems, in-car entertainment and control systems, and other electrical connections.

Aerospace field: Flexible PCB is widely used in the design of electronic systems for drones, satellites and spacecraft due to its lightweight and high reliability.

Military and defense applications: including military communications equipment, radar systems, etc.

Industrial control and automation: used in factory automation equipment, instrumentation, etc.

Technical innovation of 4-layer flexible PCB in high-end robots-Capel success case analysis

The line width and line spacing of the 4-layer flexible PCB are 0.1mm/0.1mm, which may bring many technological innovations to high-end intelligent sweeping robots.

First of all, this kind of flexible PCB design with fine line width and line spacing can provide more complex and higher-performance electronic control systems for robots. By increasing the circuit density, more functional modules can be integrated, such as sensors, processors, communication modules, etc., thereby improving the robot’s perception and decision-making capabilities.

In addition, flexible PCB with fine line width and line spacing can make the circuit more compact, helping to reduce the size and weight of the control system. This is especially important for smart sweeping robots because it can improve the robot’s flexibility and agility in narrow spaces while reducing the load on the robot itself, helping to extend battery life.

High-density line width and line spacing design can also improve the speed and stability of signal transmission, thereby speeding up the robot’s real-time response speed and decision-making accuracy. This is crucial for the intelligent sweeping robot’s functions such as movement, obstacle avoidance and map construction.

In addition, the material and structure of the flexible PCB can better adapt to the vibration and deformation of the robot during use, improving the stability and durability of the circuit. This makes the intelligent sweeping robot more adaptable to complex working scenarios and long-term operation, thus improving the reliability and service life of the entire system.

The 4-layer flexible PCB with a Board thickness of 0.2mm may bring a series of technological innovations to high-end intelligent sweeping robots.

First of all, such a thin flexible PCB design can achieve a more compact and lightweight electronic control system in the sweeping robot. The thin design can significantly reduce the thickness of the circuit board, making it easier for the entire control system to be integrated into the robot’s body, improving the robot’s flexibility and maneuverability.

In addition, the characteristics of thin flexible PCB can allow smart sweeping robots to better adapt to dynamic environments and small spaces. Its excellent flexibility and toughness make electronic components more resistant to the stress caused by robots during operations such as movement, bending and extrusion. Therefore, this design helps improve the stability and durability of intelligent sweeping robots in complex environments.

In terms of circuit design, thin flexible PCBs can achieve higher density wiring and can accommodate more electronic components. This makes it possible to implement richer and more complex electronic control systems in a limited space. For example, more sensors, processors, and communication modules can be integrated to enhance the robot’s perception and decision-making capabilities.

In addition, the excellent electrical properties of thin flexible PCB help improve the speed and stability of signal transmission, and improve the response speed and movement accuracy of intelligent sweeping robots. At the same time, thin flexible PCB also helps reduce power consumption and heat generation, improving the efficiency and reliability of the entire system.

The Minimum Aperture of 4-layer flexible PCB is 0.2mm, which may bring many technological innovations to high-end intelligent sweeping robots.

First, such small hole diameters enable high-density wiring and more complex circuit designs on flexible PCBs. This allows the internal electronic components to be arranged more compactly, thereby reducing the overall size and weight, providing more possibilities for the application of embedded intelligent control systems.

In addition, the 4-layer flexible PCB with small hole diameter also makes it possible to achieve more functions and performance in a limited space. For example, more sensors, processors and communication modules can be integrated on flexible PCBs to improve the perception, intelligent decision-making and response speed of intelligent sweeping robots. This also provides stronger support for the robot’s localization function and autonomous navigation.

In terms of electronic connections, the 4-layer flexible PCB with small hole diameter can achieve high-density welding and connection, thereby improving the reliability and stability of the circuit. This is particularly important for smart sweeping robots, because maintaining a stable and reliable connection despite movement and vibration is crucial for the robot’s long-term operation and robustness.

In addition, the smaller hole diameter also means more space within the board for wiring and component placement, thereby improving system integration and overall performance. The characteristics of flexible PCB allow it to better adapt to the deformation and deflection of the robot when it is working, making it possible to improve the stability and durability of intelligent sweeping robots in complex environments.

The copper thickness of the 4-layer flexible PCB is 12um, which may bring many technological innovations to high-end intelligent sweeping robots.

First, the thinner copper layer makes the flexible PCB more flexible and bendable. This means that in high-end intelligent sweeping robots, the shape and layout of the circuit board can be designed more flexibly to adapt to more complex and narrow robot structures, thereby improving the flexibility and adaptability of the overall design.

Secondly, a thin copper layer also means a lighter circuit board, which is crucial for the lightweight design of high-end intelligent sweeping robots. Lightweight design can improve the efficiency of the robot, reduce power consumption, and provide more space for the robot’s motion performance and durability. Therefore, flexible PCBs with thin copper layers can provide more possibilities for the design of high-end intelligent sweeping robots.

In terms of transmission performance, thin copper layers can provide higher circuit performance. The copper layer of a circuit board is used to transmit current and signals, and a thinner copper layer can reduce the resistance and signal loss of the circuit board, thus improving overall performance and efficiency. This is particularly critical for the electronic control system of intelligent sweeping robots, which can improve the accuracy and response speed of sensor data and improve the intelligence level of the robot.

In addition, thin copper layers also mean finer circuit layout and higher density. This means that more complex and sophisticated circuit designs can be implemented on flexible PCBs, providing more space for functional expansion and performance improvement of high-end intelligent sweeping robots. From the integration of more sensors to the application of more powerful processors, thin copper layer flexible PCB provides a wider range of possibilities for technological innovation of intelligent sweeping robots.

Surface Treatment: Immersion Gold of 4-layer flexible PCB may bring many technological innovations to high-end smart sweeping robots.

First, Immersion Gold surface treatment can provide excellent electrical properties and good soldering performance. For high-end intelligent sweeping robots, this means more stable and reliable electrical connections, helping to improve the performance and stability of the overall circuit. This is crucial for the connection of key components such as sensors, motor controls, and communication modules, which is beneficial to improving the accuracy and reliability of the robot.

Secondly, the Immersion Gold surface treatment provides excellent corrosion resistance and long-term stability. This is very important for the long-term stable operation of intelligent sweeping robots in harsh environments, especially when facing floor cleaning operations. Immersion Gold surface treatment helps extend the service life of the circuit board and reduces maintenance costs, thereby providing technical guarantee for the reliable and continuous operation of high-end intelligent sweeping robots.

In addition, Immersion Gold also provides a very flat and smooth surface, which facilitates higher-precision welding and assembly. In high-end intelligent sweeping robots, this means that electronic components can be arranged and assembled more flexibly, helping to achieve more complex and compact designs and increasing room for technological innovation.

In addition, the Immersion Gold surface treatment also provides good solder joint reliability and good thermal conductivity. This is very important for the stable operation and heat dissipation of the electronic control components of high-end intelligent sweeping robots, helping to improve overall performance and reliability.

The 4-layer flexible PCB’s Flame Retardant:94V0 may bring many technological innovations to high-end intelligent sweeping robots.

First of all, using Flame Retardant:94V0’s 4-layer flexible PCB can greatly improve the safety of intelligent sweeping robots. In high-end smart devices, security is a crucial consideration. Using Flame Retardant material can significantly reduce the risk of circuit board fire, resulting in a higher level of safety. This is of great significance to prevent circuit board fires caused by short circuits, overheating and other problems during use of intelligent sweeping robots.

Secondly, Flame Retardant material can also improve the reliability and stability of intelligent sweeping robots. PCBs using Flame Retardant:94V0 have better heat resistance and can withstand higher temperature environments without damage, which means that smart sweeping robots can cope with more severe working conditions, including cleaning tasks in high temperature environments or long-term Time running requirements. This helps improve the stability and reliability of the smart sweeping robot while extending its service life.

In addition, Flame Retardant materials often have better mechanical properties, including tensile strength, flexibility and other properties. This means that flexible PCBs using Flame Retardant:94V0 can better cope with external environmental factors such as vibration and shock, helping to reduce damage and breakage of circuit boards, thereby improving the stability and reliability of smart sweeping robots in actual use. .

At the same time, the 4-layer flexible PCB of Flame Retardant:94V0 also has good processing performance and plasticity, which can realize more complex and compact circuit layout and design, helping to improve the overall performance and functional innovation of intelligent sweeping robots.

Resistance Welding Color:Black of 4-layer flexible PCB may bring several technological innovations to high-end intelligent sweeping robots.

First, the 4-layer flexible PCB using Resistance Welding Color: Black can provide higher electrical connectivity and stability. Resistance welding technology ensures stronger connection points on the circuit board and more reliable electrical signal transmission. For high-end smart sweeping robots, stable electrical connections are crucial to the reliability of sensors, actuators and control units. This means that the positioning accuracy, motion control and sensor feedback accuracy of smart sweeping robots can be improved.

Secondly, Resistance Welding Color:Black technology can provide better heat dissipation performance. In high-end intelligent sweeping robots, electronic components and sensors are densely laid out, which requires high heat dissipation. By using Resistance Welding Color: Black’s 4-layer flexible PCB, the heat conductivity of the circuit board can be improved, helping to reduce hot spot accumulation and improve the heat dissipation efficiency of the overall system, avoiding performance degradation or damage caused by overheating.

In addition, Resistance Welding Color:Black can provide higher corrosion protection performance. Intelligent sweeping robots often need to work in humid, high-temperature or chemically corrosive environments, which poses challenges to the stability and reliability of circuit boards. The 4-layer flexible PCB using Resistance Welding Color: Black can increase the corrosion resistance of the circuit board, extend its service life, and improve the ability of the intelligent sweeping robot to adapt to various harsh environments.

Stiffness of 4-layer flexible PCB: Steel Sheet and FR4 can bring many technological innovations to high-end intelligent sweeping robots, improving their performance and functionality.

Improved structural stiffness and flexibility: The 4-layer flexible PCB that combines Stiffness: Steel Sheet and FR4 can maintain a certain structural stiffness while having better flexibility. This means that in the design of high-end intelligent sweeping robots, the position of electronic components can be more flexibly arranged to better adapt to the design needs of the robot’s overall structure and improve the performance and applicability of the robot in complex environments.

Optimization of weight and volume: Compared with traditional rigid PCBs, flexible PCBs can better adapt to space constraints, thus helping to reduce the overall weight and size of the robot. This means that high-end intelligent sweeping robots can be lighter and more portable, improving portability and operation convenience.

Improved durability and stability: By using the material combination of Stiffness: Steel Sheet and FR4, the 4-layer flexible PCB can have higher mechanical strength and wear resistance, thereby reducing the impact of mechanical vibration and damage on the circuit. This means that high-end intelligent sweeping robots can be more stable and durable, reducing the need for repairs and replacements and improving overall reliability.

Optimization of transmission and environmental resistance performance: Combining Steel Sheet and FR4, 4-layer flexible PCB can have good transmission performance and environmental adaptability. This means that the robot’s signal transmission in complex environments is more reliable and the circuit is more stable, which helps to improve the robot’s intelligent perception and autonomous operation capabilities.

High temperature anti-interference characteristics: FR4 material has good high temperature characteristics and anti-interference performance, which can ensure that the circuit board works stably and reliably in the high load and high temperature environment of the sweeping robot, improving the overall reliability and safety.

4 Layer Flexible PCB Prototyping and Manufacturing Process

Summary

The innovative applications of 4-layer flexible PCB technology in the field of high-end intelligent sweeping robots include line width, line spacing, board thickness, minimum aperture, minimum aperture, copper thickness,surface treatment,flame retardant,resistance welding and stiffness. These innovative technologies improve the flexibility, agility, performance stability and sensor feedback accuracy of smart sweeping robots, meet the special needs of intelligent sweeping robots systems in terms of high temperature, vibration, and high efficiency, and bring huge benefits to the development of robot.

Post time: Mar-09-2024

Back