In the manufacturing of electronic devices, especially smartphones, a key element that must be paid close attention to is the quality of the FPC (Flexible Printed Circuit) circuit board. These tiny yet crucial components play an important role in ensuring that our beloved gadgets run smoothly. In this blog post, we will delve into the key requirements that a high-quality FPC board needs to meet and their importance in ensuring optimal mobile phone performance.

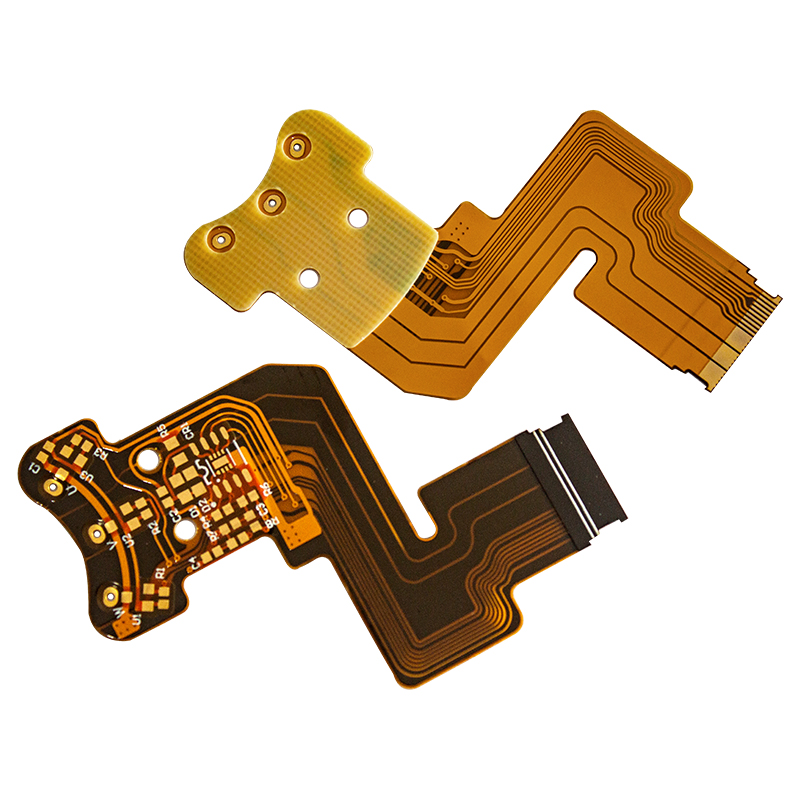

Before we dive into the specific requirements, let’s first understand what an FPC circuit board is and its uses. FPC circuit board, also known as flexible circuit, is a thin, lightweight electronic circuit board using a flexible plastic substrate. Unlike rigid circuit boards, FPC circuit boards have better flexibility and can be bent, twisted and shaped to meet the design requirements of compact electronic devices such as smartphones.

1. Electrical connection:

Once the components are installed, it’s crucial that your phone maintains good electrical connections. This requirement ensures that all circuits operate seamlessly, allowing the device to perform its intended task. Any inconsistencies or interruptions in electrical connections may cause malfunctions, rendering the phone unusable.

2. Line width, thickness and spacing:

It is crucial to maintain accurate measurements of line width, line thickness, and line spacing on FPC circuit boards. Accurate specifications in these areas are necessary to prevent wiring from heating, opens, and shorts. The traces on the FPC circuit board act as electrical pathways, facilitating the flow of electricity throughout the device. Any irregularities or deviations from required specifications may result in electrical failure and potential damage to the phone.

3. High temperature resistance:

Exposure to high temperatures is an unavoidable reality for electronic devices, especially smartphones that generate a lot of heat during operation. Therefore, a high-quality FPC circuit board must be able to withstand high temperatures without problems such as copper peeling off. A safe and reliable connection between copper and substrate is critical to ensure device stability and functionality.

4. Prevent oxidation:

Copper is an excellent electrical conductor and is often used in FPC circuit boards. However, copper surfaces are susceptible to oxidation, especially when exposed to environmental factors such as moisture and air. Oxidation not only affects the appearance of the board, it also hinders the speed of installation and can lead to premature device failure. To maintain optimal performance, FPC circuit boards must be designed and manufactured with appropriate anti-oxidation measures.

5. Minimize electromagnetic radiation:

In today’s technology-driven world, electronic devices are everywhere. As much as we love our smartphones, it’s crucial to make sure they don’t emit too much electromagnetic radiation. High-quality FPC circuit boards should be designed to minimize electromagnetic interference and radiation to protect users and other electronic equipment from potential health hazards or signal interruptions.

6. Prevent deformation:

Aesthetics and structural integrity are also important aspects to consider when manufacturing FPC circuit boards. The appearance of the board should not be deformed to avoid deformation of the mobile phone casing or misalignment of the screw holes during subsequent installation. Given current mechanized installation processes, any errors in hole placement or circuit design can cause serious problems. Therefore, FPC circuit boards should be designed and manufactured with the highest precision to ensure that any deformation is within acceptable limits.

7. Environmental resistance:

In addition to being able to withstand high temperatures, high-quality FPC circuit boards should also be resistant to other environmental factors such as high humidity. Electronic devices are frequently exposed to varying climate conditions, and FPC circuit boards must maintain their functionality and integrity regardless of the external environment. Special coatings or laminates can be applied to the panels to provide additional protection against environmental stresses.

8. Mechanical properties:

The mechanical properties of the FPC circuit board surface must meet the installation requirements. Since the circuit board is an integral part of the phone’s internal structure, it must have sufficient mechanical strength and durability to withstand the installation process. Sufficient rigidity, reliability and resistance to mechanical stress are crucial to ensure easy integration into mobile phone assembly and longevity of the device.

In summary

High-quality FPC circuit boards play a vital role in ensuring optimal performance of smartphones and other electronic devices. They must meet specific requirements to ensure correct electrical connections, precise line measurement, resistance to high temperatures and oxidation, minimal electromagnetic radiation, protection against deformation, environmental resistance and adequate mechanical properties. Manufacturers and designers need to prioritize these requirements to deliver products that not only provide a seamless user experience but also stand the test of time. By adhering to these standards, we can continue to enjoy the wonders of modern technology without compromising performance or reliability.

Post time: Oct-23-2023

Back