In today’s fast-paced world, technology plays a vital role in almost every aspect of our lives. From the gadgets we use in our daily lives to life-saving advanced medical devices, reliable and efficient electronic components are the backbone of these technological advancements. When it comes to manufacturing beauty instrument medical device flex PCBs, one name stands out – Capel.

How Fast Turn Flex PCB Manufacturer Capel Provides Reliability Solutions for Aesthetic Instrument Medical Device

Manufacturers:

Capel is a leading PCB solutions provider focused on rapid flex PCB manufacturing. With a state-of-the-art in-line single-layer PCB fabrication facility, they offer unrivaled quality and efficiency. Their commitment to innovation and reliability has made them the first choice of medical device manufacturers of aesthetic instruments worldwide.

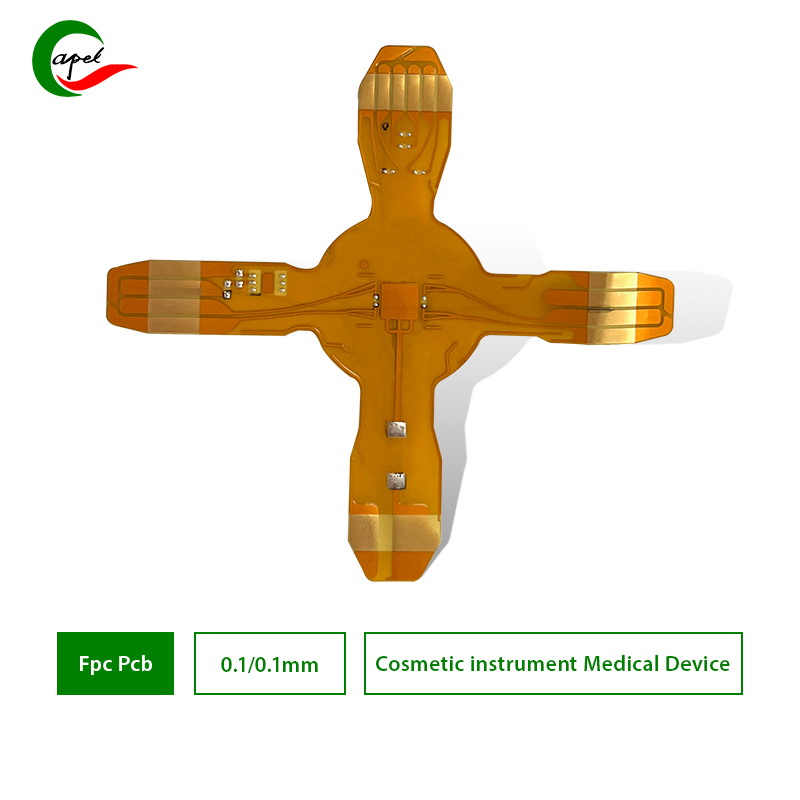

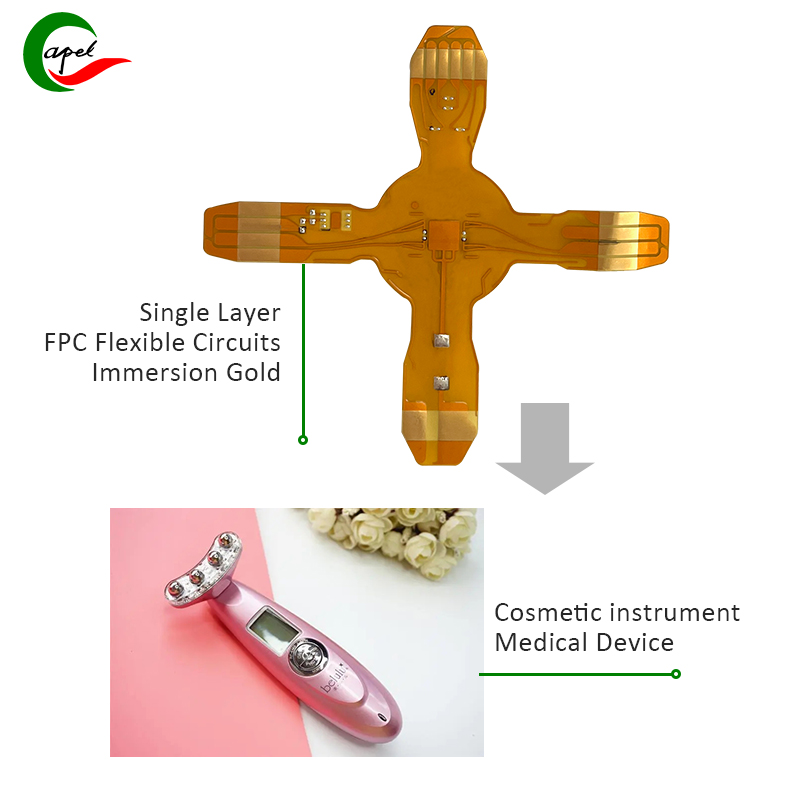

One of the key features of Capel’s rapid flex PCB manufacturing is the use of single-layer PCBs. These flexible circuits offer many benefits for medical devices, including cosmetic instruments. Another advantage of using single-layer PCBs in medical devices is that they provide better thermal management than multi-layer PCBs. This is critical for devices that generate heat as it helps prevent overheating and ensures the longevity of the device. The 0.1/0.1mm line width and pitch provided by Capel’s fast flex PCB manufacturing process enables precise signal transmission. This is critical for medical devices, where accurate data transmission is critical for patient monitoring, diagnosis and treatment. A thin board thickness of 0.1mm makes the PCB lightweight and flexible, allowing it to be easily integrated and mounted in compact medical devices. This ensures that the device remains portable and comfortable for the patient without sacrificing functionality or performance. Capel’s fast flex PCB manufacturing process also ensures high reliability and durability of the PCB. This is very important for medical devices as they need to operate consistently and reliably even under demanding and critical conditions.

The 18um copper thickness is another key feature that sets Capel’s fast turn PCBs apart from the competition, which facilitates efficient power transfer within the circuit. This ensures that the PCB can efficiently meet the beauty instrument’s power requirements, thereby contributing to its overall functionality. In addition, the 18um copper thickness also enhances the durability and lifespan of the PCB. Thicker layers of copper provide better resistance to wear, tear, and environmental elements, extending the life of the PCB and, ultimately, the beauty instrument it’s used in. Additionally, the 0.3mm minimum aperture is a valuable feature that adds to the versatility of Capel PCBs. This means that these PCBs can accommodate smaller components and more compact circuit designs, allowing greater flexibility in the development of beauty devices. The use of smaller components and more compact circuit designs can help achieve miniaturization, optimize space utilization, and improve the overall aesthetics of the instrument

When it comes to safety, Capel leaves no stone unturned. The use of flame retardant materials (94V0) in Capel single sided PCBs is a critical safety measure. The material is designed to reduce the risk of fire and prevent the spread of flames, making medical devices safe for use in cosmetic devices. The 94V0 rating indicates that the material has passed rigorous flame retardant tests and meets the highest safety standards. This ensures that even in the event of a potentially hazardous situation, the PCB will not contribute to the ignition or spread of the fire. This is especially important for medical devices and cosmetic instruments where safety is paramount. By using flame retardant materials, Capel ensures that its PCBs provide an additional layer of protection, making aesthetic instruments medical devices reliable and safe for use in various environments. This commitment to safety reinforces their commitment to meeting the highest standards in the industry.

In addition, Capel’s circuit PCBs have a surface treatment called immersion gold. This treatment has several advantages that improve PCB performance and reliability. First of all, immersion gold has excellent solderability, which means that it can achieve a strong and reliable solder connection between the component and the PCB. This is especially important for beauty instruments and medical equipment, where a reliable connection is critical for proper operation. In addition, immersion gold has high corrosion resistance. It forms a protective layer on the PCB to prevent oxidation and corrosion which can reduce the performance and life of the PCB. This ensures that Capel’s PCBs will maintain their functionality and reliability over the long term, even in challenging environments. In addition, the yellow resistance welding color not only adds to the beauty instrument’s aesthetic value, but also enhances its visual appeal. This is especially important for consumer-facing products, since appearance plays an important role in customer satisfaction.

Capel understands the unique requirements of the medical industry, especially in the manufacture of aesthetic instruments. That’s why their PCBs are specifically designed to meet the demanding needs of this industry. From precise line widths to superior copper thickness, every aspect of Capel’s Fast Flex PCBs has been carefully engineered to deliver optimum performance and reliability.

In addition, Capel offers a range of services beyond PCB manufacturing. Through their online ordering system, customers can conveniently order PCBs and get instant quotes. Their rapid PCB prototyping and assembly services ensure fast turnaround times, allowing cosmetic instrument medical device manufacturers to stay ahead of the competition.

In addition to PCB fabrication, Capel also specializes in Surface Mount Technology (SMT) PCB assembly. The service provides a one-stop solution for manufacturers of aesthetic instruments and medical equipment, eliminating the hassle of finding multiple suppliers for different components. Working with Capel, you can rest assured that every aspect of your PCB fabrication and assembly needs will be taken care of.

Flex PCB Manufacturer Capel is the ultimate solution for aesthetic instrument medical equipment manufacturers. With a commitment to innovation, reliability, and exceptional customer service, Capel has become an industry leader in providing PCB solutions. Whether you need rapid PCB prototyping or full PCB assembly, Capel has you covered. Trust Capel for all your PCB needs and experience the difference in quality and performance.

Post time: Sep-06-2023

Back