When manufacturing low-cost PCB prototypes, ensuring their quality is critical. You want to create a prototype that not only meets your design requirements but also performs reliably and accurately. In this blog post, we’ll look at how to ensure the quality of low-cost PCB prototypes and introduce Capel, a company that specializes in high-quality PCB prototypes.

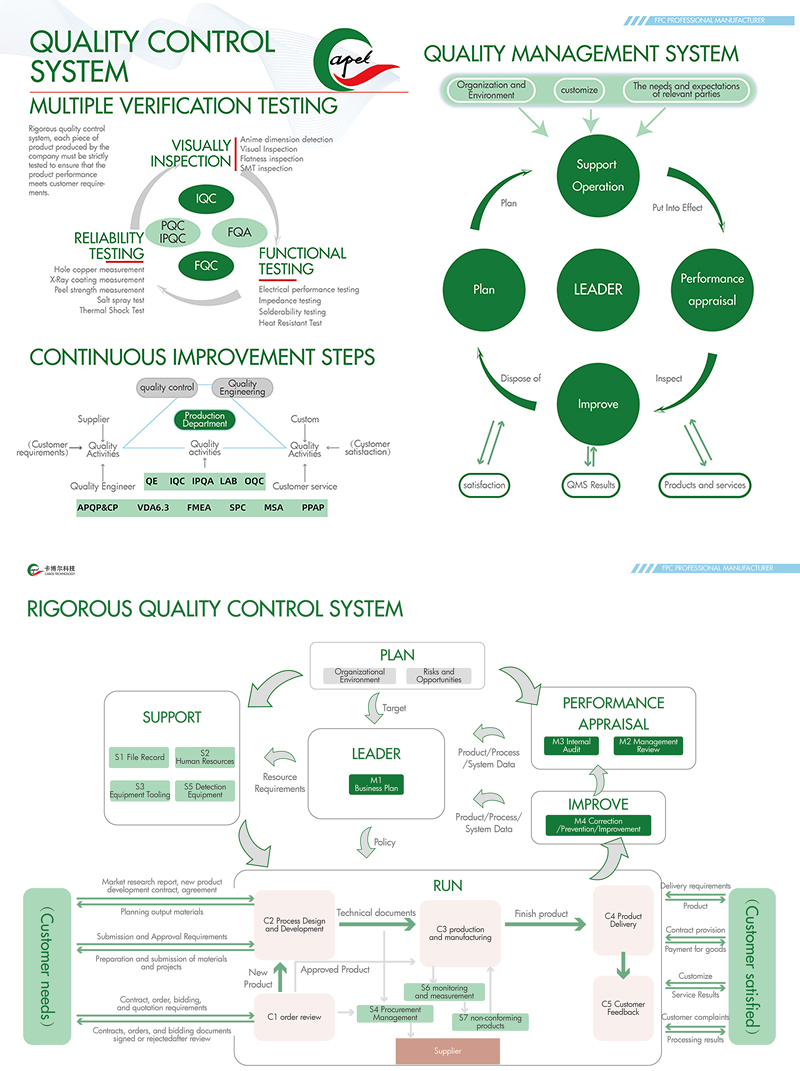

Capel is a leading PCB prototype manufacturer and they have a strong reputation for their strict quality control system. They understand the importance of PCB prototype quality and take numerous measures to ensure that every prototype they manufacture meets the highest standards.

One of the ways Capel ensures quality is through their certifications and logos. Capel is ISO 14001:2015, ISO 9001:2015 and IATF16949:2016 certified. These certifications demonstrate that Capel follows an internationally recognized quality management system to ensure consistent production and customer satisfaction. In addition, Capel’s PCB prototypes carry UL and ROHS marks, proving compliance with safety and environmental standards.

Moreover, Capel has been recognized by the government as an enterprise that “observes contracts and keeps promises.” This recognition highlights Capel’s commitment to upholding ethical business practices and delivering on its promises. In addition, Capel has been recognized as a “National High-tech Enterprise”, consolidating its leading position in the PCB prototype manufacturing industry.

In addition to certifications and government recognition, Capel is committed to innovation. They have been awarded a total of 16 utility patents, demonstrating their commitment to developing new and improved PCB prototyping solutions. Through innovative approaches, Capel continuously strives to improve the quality of prototypes and provide cutting-edge solutions to its customers.

Now that we’ve established Capel’s commitment to PCB prototype manufacturing quality, let’s dive into some strategies you can implement to ensure the quality of your low-cost PCB prototypes.

First, it’s crucial to work closely with the manufacturer you choose. Communication is key to communicating your design requirements and expectations. By establishing clear lines of communication, you can ensure that the manufacturer understands your needs and can address any concerns or questions you may have along the way.

Additionally, providing detailed documentation can greatly improve the quality of your PCB prototype. This includes detailed design documents, manufacturing specifications, and any other information that can help manufacturers accurately produce prototypes. Clear and comprehensive documentation eliminates ambiguity and reduces the chance of errors or misunderstandings.

It is also important to conduct thorough quality checks at multiple stages of the manufacturing process. A reputable manufacturer like Capel will have their own quality control procedures, but it’s always beneficial to do your own inspections and testing. This may involve visual inspection, functional testing and performance evaluation to ensure the prototype meets your expectations.

Another aspect to consider is choosing high-quality materials for your PCB prototype. Choosing a reliable and reputable supplier for your components can greatly impact the overall quality and longevity of your prototype. It is crucial to source parts from trusted suppliers that offer authentic parts.

In addition, design for manufacturability (DFM) should not be ignored. By keeping DFM principles in mind when designing your PCB prototype, you can improve its manufacturability and reduce the chance of errors or issues during production. Working with manufacturers during the design phase can help optimize designs for efficient production and higher quality results.

Finally, continuous improvement and feedback are critical to ensuring the quality of low-cost PCB prototypes. Requesting feedback from manufacturers and incorporating lessons learned into future designs can drive continuous improvement. This collaborative approach builds strong relationships with your manufacturers and encourages a shared commitment to delivering high-quality prototypes.

In summary, when manufacturing low-cost PCB prototypes, ensuring their quality is crucial. Companies like Capel, with strict quality control systems and an impressive track record, are capable of delivering best-in-class prototypes. By working closely with your manufacturer, providing detailed documentation, performing thorough quality checks, selecting high-quality materials, following DFM principles, and seeking continuous improvement, you can ensure the quality of your PCB prototypes and achieve your desired results.

Post time: Oct-13-2023

Back