In this blog, we will explore the different types of rigid-flex circuit boards on the market today and shed light on their applications. We’ll also take a closer look at Capel, a leading rigid-flex PCB manufacturer, and highlight their products in this area.

Rigid-flex circuit boards revolutionize the electronics industry by offering a unique combination of flexibility and durability. These boards are specifically designed to meet the demanding requirements of modern electronic devices, where space constraints and complex designs often pose significant challenges.

1. Single-sided rigid flex circuit boards:

Single-sided rigid-flex PCBs consist of a single rigid layer and a single flex layer, connected by plated through holes or flex-to-rigid connectors. These boards are typically used in applications where cost is a key factor and the design does not require a lot of complexity or layering. While they may not offer as much design flexibility as multilayer PCBs, single-sided rigid-flex PCBs can still offer significant advantages in terms of space savings and reliability.

2. Double-sided rigid flexible PCBs :

Double-sided rigid-flex PCBs have two rigid layers and one or more flex layers interconnected by vias or flex-to-flex connectors. This type of board allows for more complex circuits and designs, allowing for increased flexibility in routing components and signals. Double-sided rigid-flex boards are widely used in applications where space optimization and reliability are critical, such as portable consumer electronics, medical devices, and aerospace systems.

3. Multi-layer rigid-flex circuit board:

Multilayer rigid-flex circuit boards are composed of multiple flexible layers sandwiched between rigid layers to form complex three-dimensional structures. These boards offer the highest level of design flexibility, allowing complex layouts and advanced features such as impedance control, controlled impedance routing and high-speed signal transmission. The ability to integrate multiple layers into a single board can result in significant space savings and enhanced reliability. Multilayer rigid-flex circuit boards are commonly found in high-end electronics, automotive systems, and telecommunications equipment.

4. HDI rigid flex PCBs boards:

HDI (High Density Interconnect) rigid-flex PCBs use microvias and advanced interconnect technology to enable higher density components and interconnects in a smaller form factor. HDI technology enables finer pitch components, smaller via sizes, and increased routing complexity. These boards are typically used in small electronic devices such as smartphones, wearables, and IoT (Internet of Things) devices where space is limited and performance is critical.

5. 2-32 layers of rigid flexible circuit boards:

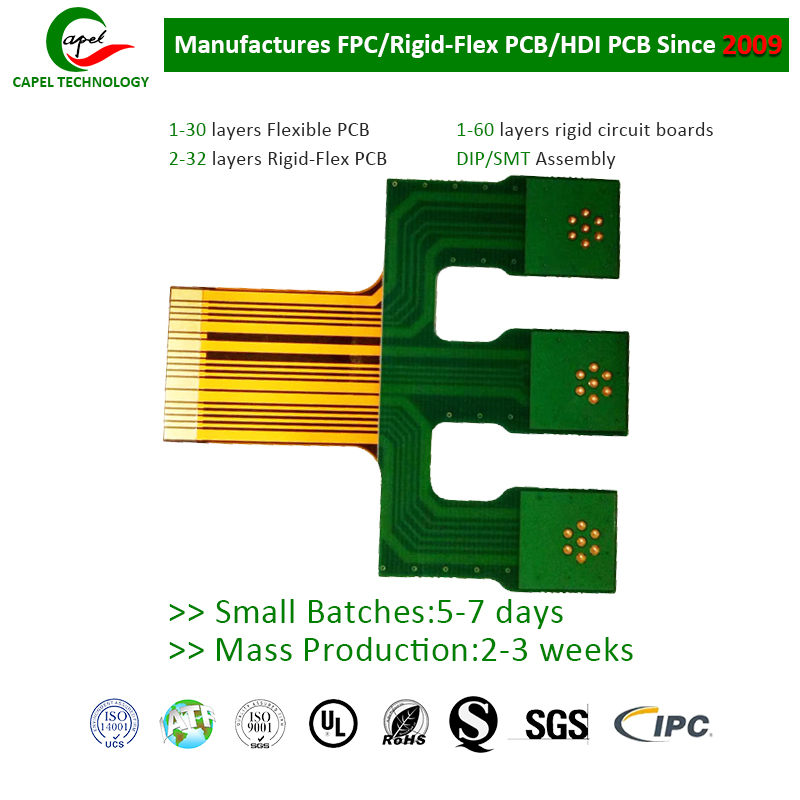

Capel is a well-known rigid-flex PCB manufacturer that has been serving the electronics industry since 2009. With a strong focus on quality and innovation, Capel offers a wide range of rigid-flex PCB solutions. Their product portfolio includes single-sided rigid-flex PCBs, double-sided rigid-flex PCBs, multi-layer rigid-flex circuit boards, HDI rigid-flex PCBs, and even boards up to 32 layers. This comprehensive offering enables customers to find the solution that best suits their specific application needs, whether it is a compact wearable device or a complex aerospace system.

In Summary

There are many types of rigid-flex circuit boards, each designed to meet specific design requirements and applications. Capel has extensive experience and expertise and is a leading provider of rigid-flex PCB solutions, offering a diverse range of circuit boards to meet the ever-changing needs of the electronics industry. Whether you are looking for a simple single-sided PCB or a complex multi-layer HDI board, Capel can provide the right solution to turn your innovative ideas into reality.

Post time: Sep-18-2023

Back