In this blog post, we will explore various techniques and considerations to ensure that the thickness of a 6-layer PCB remains within the required parameters.

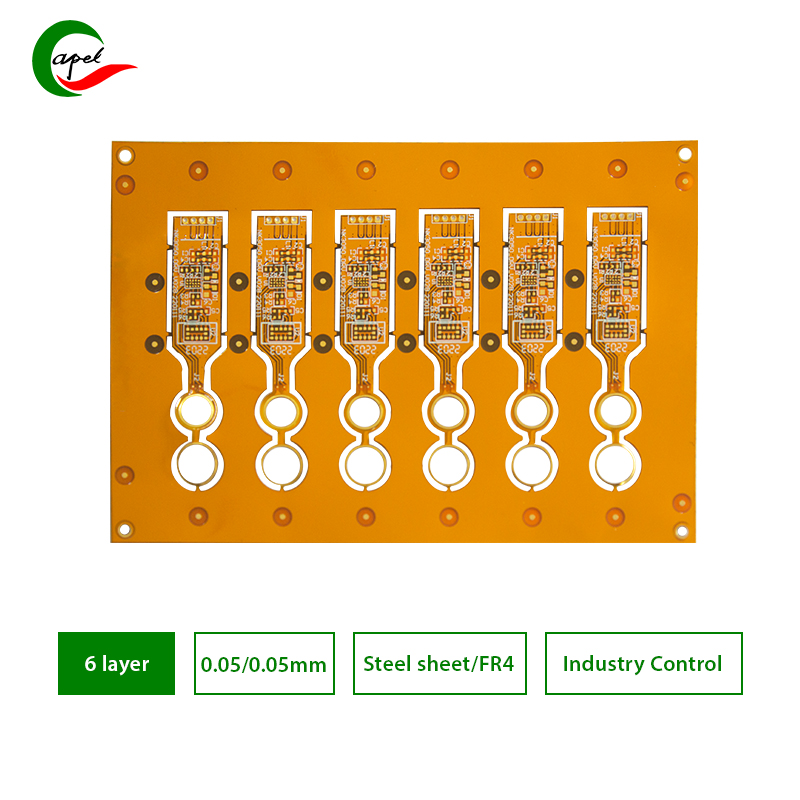

As technology develops, electronic devices continue to become smaller and more powerful. This advancement has led to the development of complex circuits, requiring more complex printed circuit boards (PCBs). One common PCB type is the 6-layer PCB, which provides enhanced functionality and reliability. However, a key factor to consider when designing and manufacturing a 6-layer PCB is keeping its thickness within the allowable range.

1. Understand the specifications:

In order to effectively control the thickness of a 6-layer PCB, it is important to be familiar with the specifications and requirements imposed by the manufacturer or customer. These specifications usually include a specific range within which the thickness should be maintained. Review these guidelines carefully and make sure you fully understand the tolerance limits.

2. Choose the right material:

When working with 6-layer PCBs, choosing the right materials is critical. Different materials have different thicknesses, which can significantly affect the final thickness of the PCB. Conduct thorough research to identify materials that meet the desired functional and mechanical requirements while providing the thickness range you require. Consider consulting with a materials expert or supplier to learn more about the options for your specific project.

3. Consider copper thickness:

The copper layer in a 6-layer PCB plays a vital role in its functionality. However, they also affect overall thickness. It is critical to determine the correct copper thickness required for your design and ensure it fits within your desired thickness range. Consider the trade-offs between cost, electrical performance, and thickness to find the best balance.

4. Implement precise manufacturing processes:

In order to maintain control over the 6-layer PCB thickness, it is critical to implement a precise manufacturing process. This involves taking appropriate quality control measures throughout the production stages. Utilize advanced manufacturing techniques such as laser drilling and precision etching to achieve precise layer alignment and avoid any unexpected thickness variations.

5. Work with an experienced PCB manufacturer:

Working with an experienced and reputable PCB manufacturer can make a significant contribution to controlling the thickness of a 6-layer PCB. These professionals have in-depth knowledge and expertise in PCB manufacturing, ensuring that your design specifications are accurately met. Working closely with the manufacturer can also help you resolve any issues or challenges that arise during the manufacturing process.

6. Carry out regular tests and inspections:

Thorough testing and inspection is critical to identify any changes in 6-layer PCB thickness. Implement a comprehensive quality control program including dimensional measurements and material analysis. This will help identify any deviations from the required thickness range at an early stage so that corrective measures can be taken promptly.

In short

Controlling the thickness of the 6-layer PCB within the allowable range is crucial to ensure its functionality and reliability. By understanding the specifications, carefully selecting materials, considering copper thickness, implementing a precise manufacturing process, working with an experienced manufacturer, and conducting regular testing, you can confidently design and manufacture a 6-layer PCB that meets the required thickness requirements. Following these best practices not only produces high-quality PCBs, it also streamlines the manufacturing process and saves time and resources.

Post time: Sep-26-2023

Back