Introduction

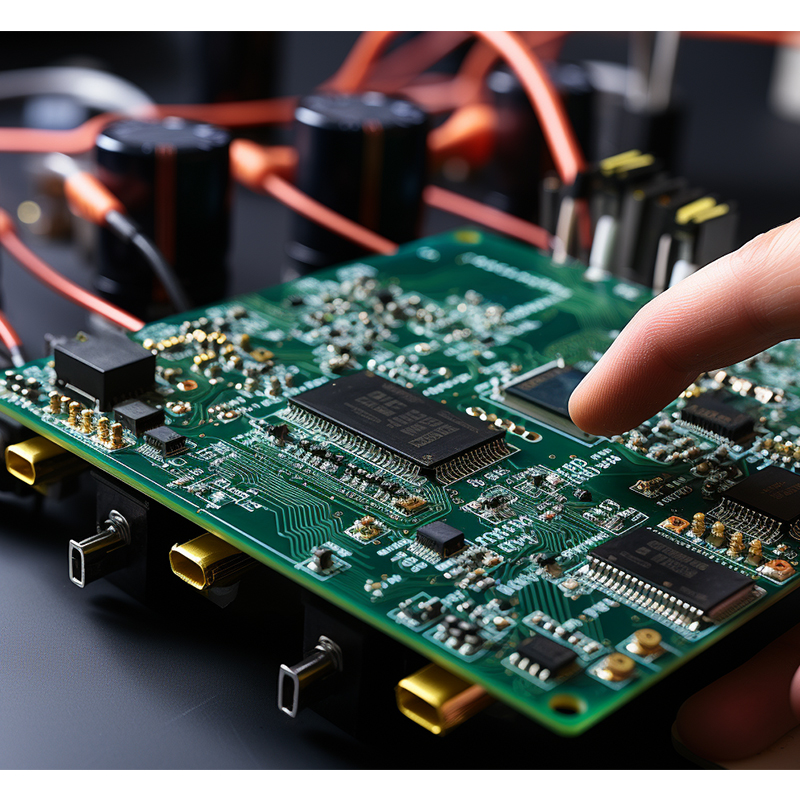

Welcome to our comprehensive guide to common problems that can arise when soldering circuit boards. Soldering is a critical process in electronic device manufacturing, and any issues can lead to incorrect connections, component failure, and a decrease in overall product quality. In this blog post, we will discuss various issues that can arise during circuit board soldering, including PCB opens, component misalignment, soldering issues, and human error. We’ll also share effective troubleshooting tips to help you overcome these challenges and ensure reliable soldering during your electronics assembly process.

1. PCB open circuit: causes and solutions

One of the most common problems in circuit board soldering is an open circuit, which is an incomplete or missing connection between two points on the PCB. The main reasons for this problem are bad solder joints or broken conductive traces on the PCB. To resolve this issue, consider the following solutions:

- Check the solder joints: Carefully inspect each solder joint to identify any loose or incomplete connections. If any faults are found, rework the joint using suitable soldering techniques.

- Verify PCB design: Check the PCB design for any issues related to circuit layout, insufficient trace spacing, or incorrect routing. Correct the design to avoid open circuit problems.

- Perform a continuity test: Use a multimeter to detect any discontinuities in the circuit traces. Focus on the affected areas and rework these connections as needed.

2. Component Misalignment: Troubleshooting Guide

Improper alignment or spacing of components can lead to manufacturing defects and electronic device failure. Here are some practical tips for solving misalignment issues:

- Perform a visual inspection: Inspect the entire PCB assembly and verify the placement and alignment of each component. Look for any components that are bent, touching adjacent parts, or incorrectly positioned. Adjust them carefully using the appropriate tools.

- Check component specifications: Check data sheets and component specifications to ensure accurate positioning and orientation during assembly. Incorrect component insertion may cause functional issues.

- Utilize jigs and fixtures: Using jigs, fixtures and templates can improve accuracy and consistency in component placement. These tools help align and secure components in the correct position, minimizing the possibility of misalignment.

3. Welding Problems: Troubleshooting Common Defects

Soldering problems can seriously affect the performance and reliability of circuit board soldering. Let’s explore some common soldering defects and related troubleshooting tips:

- Disturbed solder joints: This occurs when the soldered connection becomes disturbed during the cooling process. To prevent interference with the solder joint, make sure the component and PCB remain still after soldering until the solder has completely cooled and solidified.

- Cold welding: Cold welding spots are caused by insufficient heat during the welding process. The solder may not bond properly, resulting in poor electrical and mechanical connections. Use sufficient heat during soldering and verify that the solder flows smoothly, covering the component leads and pads.

- Solder bridging: Solder bridging occurs when excess solder creates an unintended connection between two adjacent pins or pads. Check each joint carefully and remove excess solder with a desoldering tool or solder wire. Make sure there is proper clearance between the pins and pads to prevent future bridging.

- Pad damage: Overheating during soldering can damage PCB pads, affecting electrical connections. Take precautions to avoid prolonged exposure of pads to high temperatures.

4. Human Error: Preventing Welding Errors

Despite advances in automation, human error remains a significant cause of welding defects. Here are some precautions to minimize errors:

- Training and skills development: Make sure your employees are properly trained and up to date on the latest welding procedures and techniques. Ongoing skill development programs enhance their expertise and minimize human errors.

- Standard Operating Procedures (SOPs): Implement SOPs specific to the circuit board soldering process. These standardized guidelines will help streamline operations, minimize variation, and reduce errors.

- Quality Control Inspections: Incorporate strict quality control inspections throughout the welding process. Conduct regular inspections and correct problems promptly if found.

Conclusion

Circuit board soldering is an important part of electronics manufacturing. By understanding the potential problems that can arise during this process, you can take proactive steps to prevent them. Remember to check solder joints, align components accurately, resolve soldering defects promptly, and take precautions to prevent human error. Following these guidelines will help you overcome these challenges and ensure a reliable and high-quality welding process. Happy welding!

Post time: Oct-23-2023

Back