Introduction

Cleaning and customizing flexible PCBs is an important step in various industries to ensure optimal performance and reliability. In this comprehensive guide, we will explore the importance of cleaning and customizing flex PCBs, discuss different cleaning methods, delve into the process of custom flex PCBs, examine the benefits of FR4 flex boards, understand semi-flexible PCBs, and highlight cleaning and custom flex Importance of PCBs. Flexible PCB substrates and provide insights into flexible PCB assembly technology. After reading this guide, you will have a comprehensive understanding of how to select the correct substrate and assembly technology for flexible PCBs, ensuring the best process and technology for your application.

Understanding Cleaning Flexible PCBs

A. Definition and Importance of PCB Cleaning

Cleanliness of flexible PCBs is crucial in various industries. Ensuring flex PCBs are clean prevents signal loss, improves signal integrity and enhances reliability.

B. Flexible PCB cleaning technology

Ultrasonic cleaning: Explore the process of cleaning flexible PCB using ultrasonic technology.

Brush and Swab Cleaning: Learn more about manual cleaning methods using brushes and swabs.

Vapor Degreasing: Learn how vapor degreasing effectively cleans flexible PCBs.

Tips for Choosing Appropriate Cleaning Techniques: Considerations for choosing the right cleaning method based on the application and complexity of the circuit board.

Cleaning Flexible PCB Handling and Storage Recommendations: Best practices for handling and storing cleaned flexible PCBs.

Custom Flexible PCB A. Custom Flexible PCB Overview Custom flex PCBs are tailored to meet specific requirements and applications and offer many advantages over standard designs.

Factors to consider when customizing flexible PCB

Design Constraints and Flexibility Requirements: Analyze the design constraints and required flexibility of custom flexible PCBs.

Bending radius, number of layers, and component placement: important considerations during the customization process.

The importance of working with a PCB manufacturer: Work with an experienced PCB manufacturer for a seamless custom design.

Explore FR4 Flexible Circuit Boards A. Introduction to FR4 Flexible Circuit Boards FR4 is a commonly used substrate material for flexible PCBs that offers flexibility, durability and cost-effectiveness.

FR4 Flexible Circuit Board Design Guide

FR4 Material Design Considerations: Examine the design considerations specific to FR4 flexible circuit boards.

Recommendations for trace width, via layout, and pad size: A guide to optimizing the electrical performance of FR4 flexible circuit boards.

Design for Manufacturability: Practical tips for designing FR4 flexible circuit boards that are easy to manufacture.

Semi-Flexible PCBs: The Middle Ground A. Understanding Semi-Flexible PCBs Semi-flexible PCBs are suitable for applications that require bending and limited bending and offer advantages over rigid and flexible PCBs.

Semi-Flexible PCB Design Guide

Design considerations for achieving a balance between rigidity and flexibility: Learn more about designing semi-flexible PCBs to meet specific application requirements.

Recommended Materials and Layer Configurations: Select the correct materials and layer configurations for semi-flexible PCBs.

Maximizing Performance with Flexible PCB Substrates A. Importance of Flexible PCB Substrates The choice of substrate material significantly affects the performance and functionality of a flexible PCB.

Selection criteria for flexible PCB substrates

Factors to consider when choosing the right substrate material: Key considerations in choosing the right substrate material.

Balance flexibility, temperature range and dielectric properties: achieve the best balance for your application.

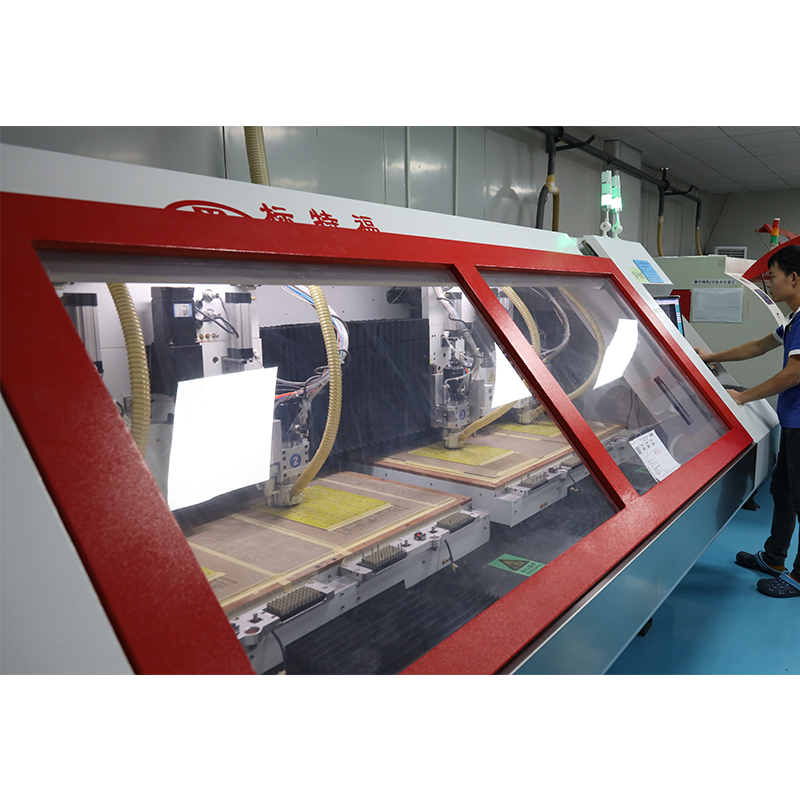

Avoid Common Pitfalls: Flexible PCB Assembly Technology A. Introduction to Flexible PCB Assembly

Challenges and Considerations of Assembling Flexible PCBs: Learn about the unique challenges faced during flexible PCB assembly.

Overview of Traditional and Advanced Assembly Technologies: Explore different assembly technologies for flexible PCBs.

Explore flexible PCB thermal adhesive and WD-40

Examination of hot glue as an adhesive material for flexible PCBs: Evaluating the use of hot glue in flexible PCB assembly.

Discussion of WD-40 as a lubricant for flexible PCB assembly and maintenance: Explore the role of WD-40 in flexible PCB assembly and maintenance.

Best Practices and Precautions: Highlights best practices and precautions for using hot glue and WD-40 in flexible PCB assembly.

Summary

In this guide, we discussed the importance of cleaning and customizing flex PCBs, explored different cleaning methods, highlighted the benefits of custom flex PCBs and FR4 flex boards, looked at the concept of semi-flexible PCBs, highlighted flex PCBs importance. PCB substrates and provides insights into flexible PCB assembly technology. By following the guidelines provided, you can ensure optimal performance and reliability of your flexible PCB. For further help and guidance tailored to your specific requirements or application, please consult experienced PCB manufacturers and suppliers.

Post time: Nov-10-2023

Back