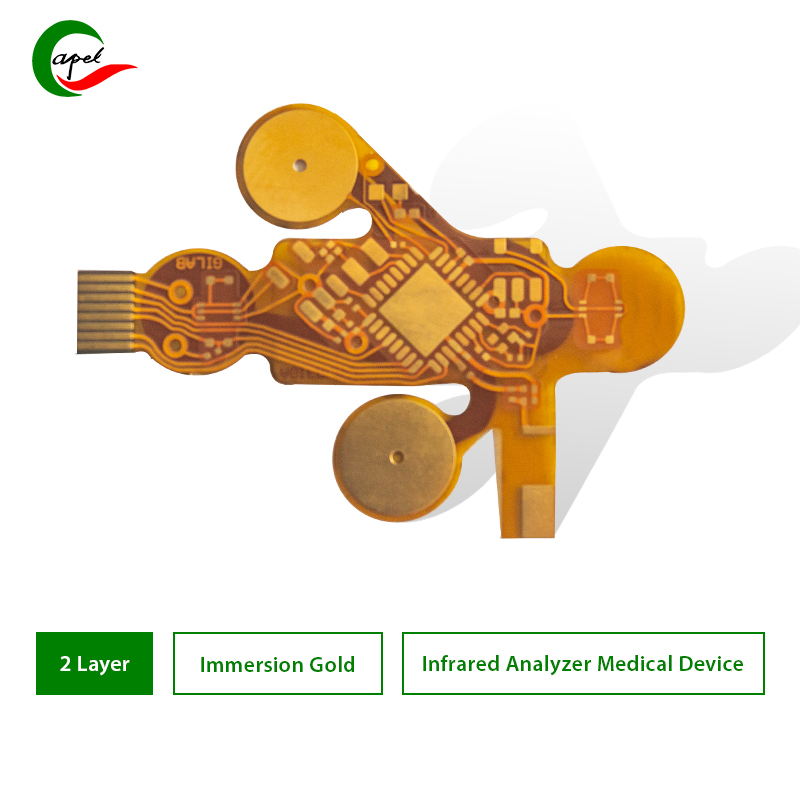

In the highly competitive world of medical device manufacturing, reliability and precision are critical. Manufacturers are constantly looking for innovative solutions to enhance their products and ensure their reliability. Printed circuit boards (PCBs) are one of the key components that play an important role in the performance and reliability of medical devices. In this blog post, we’ll explore how Capel’s gold-immersed double-sided PCBs offer a unique reliability solution for medical device manufacturers, particularly infrared analyzer devices.

How Capel’s Gold-Immersion Double-Sided PCB Provides a Reliability Solution for Infrared

Analyzer Medical Device Manufacturers:

Capel’s gold-immersion double-sided PCB is a cutting-edge solution that combines advanced technology with superior functionality to meet the specific needs of infrared analyzer medical device manufacturers. Immersion gold surface treatment has many advantages such as improved electrical conductivity, enhanced solderability and superior corrosion resistance. These characteristics make them ideal for medical devices that require high precision and stability.

One of the key features of Capel’s double-sided PCBs is their flexibility. This kind of flexible PCB board is also called flexible circuit board, compared with the traditional rigid PCB, its design has stronger adaptability and versatility. The flexibility of this PCB allows it to be fitted into compact and irregularly shaped devices such as infrared analyzers. This feature is especially useful for medical device manufacturers who require miniaturization without compromising performance.

Capel’s 2-layer flex PCB boards are optimized for medical device applications. Its design incorporates custom board functionality, allowing manufacturers to tailor the PCB to their specific requirements. In addition to customization, Capel’s fast PCB fabrication services ensure fast turnaround times, allowing medical device manufacturers to meet tight project deadlines.

Capel’s double-sided PCBs offer excellent line width and space specifications of 0.12 mm and 0.1 mm, respectively. These tight tolerances ensure optimal signal transmission and prevent signal interference in infrared analyzer equipment. Signal accuracy is critical for medical devices, especially infrared analyzers, where accurate measurements play an important role in diagnosis and therapy. By maintaining such tight tolerances, Capel’s double-sided PCB ensures accurate signal transmission without any loss or distortion. This is critical for infrared analyzer equipment, where even small signal disturbances can cause inaccurate results and potentially affect patient care. In addition, the slim and lightweight design of Capel’s double-sided PCB, with a board thickness of 0.15mm, helps to improve the overall portability and ease of use of medical devices. Infrared analyzers are typically hand-held or portable devices whose size and weight are key factors in their usability and effectiveness. The thin and light nature of Capel’s double-sided PCBs not only enables compact designs, but also helps reduce the overall weight of medical devices. This lightweight feature enhances the device’s portability, allowing healthcare professionals to easily carry the device during patient consultations and exams. Additionally, the thin design of Capel’s double-sided PCBs facilitates integration with other components and systems within medical devices. Since the space available for these devices is limited, thin PCBs allow for more efficient use of the available interior space. In turn, this allows for the addition of additional features and functionality without compromising the overall size and weight of the device.

The copper thickness of Capel’s double-sided PCB is indeed a critical factor for infrared analyzers. 18um copper thickness provides excellent electrical conductivity, ensuring efficient signal transmission between components. Infrared analyzers rely on accurate, timely data processing to provide precise measurements and analysis. Any loss or interference in signal transmission can compromise the accuracy of results, lead to erroneous interpretations and potentially affect medical decisions. Capel’s double-sided PCB copper thickness is 18um for efficient and reliable signal transmission with minimal signal attenuation or loss. This ensures that the data collected by the infrared analyzer is accurately processed and analyzed, resulting in more precise and reliable measurements. The excellent conductivity provided by the 18um copper thickness also helps to minimize signal noise and interference, which is critical for infrared analyzers dealing with sensitive signals and measurements.

A minimum aperture of 0.15mm is critical for precise placement and soldering of components on PCBs used in infrared analyzers. This feature plays a vital role in ensuring the precise positioning of sensitive components, which is essential for optimal functionality and reliability of the infrared analyzer. Infrared analyzers typically consist of many sensitive components that must be properly placed on the PCB for accurate measurements. These components may include infrared sensors, microcontrollers, memory chips and other critical electronic components. Capel’s double-sided PCBs have a minimum aperture of 0.15 mm, allowing precise and secure placement of these sensitive components during assembly. Smaller hole sizes help ensure that components fit snugly in place on the PCB, minimizing the risk of movement or misalignment during use. Accurate placement of components is critical for a variety of reasons. It helps to maintain the required distance between components to avoid any interference or crosstalk which could negatively affect the accuracy of the IR analyzer measurements. In addition, precise placement contributes to the overall stability and reliability of the PCB, reducing the risk of loose parts or poor connections that could lead to failure or unreliable readings. Additionally, small apertures are critical for reliable soldering. The compact size of the holes provides better surface tension during soldering, resulting in a stronger and more secure connection between the component and the PCB. This helps ensure the longevity and durability of the infrared analyzer electronics.

The flame retardant performance of 94V0 is indeed a significant advantage of Capel double-sided PCB. This classification indicates that the PCB material meets fire safety standards and has excellent flame retardant properties. In medical environments where safety is paramount, the use of flame retardant materials is critical. Medical equipment and devices, including PCBs, need to comply with strict safety regulations to minimize any potential hazards such as fire accidents. The flame retardant properties of 94V0 help ensure that PCBs are less likely to ignite or contribute to the spread of fire. The risk of fire-related accidents or damage in healthcare environments can be significantly reduced through the use of flame retardant materials such as 94V0. In the event of a fire, these materials are self-extinguishing, preventing the flame from spreading further and minimizing the potential for injury to medical staff, patients and surrounding equipment. In addition, the use of flame-retardant PCB materials also helps prevent the release of toxic gases and harmful smoke in the event of a fire. This is especially important in healthcare settings where patients may already be compromised or vulnerable.

Capel’s double-sided PCBs are available in two different materials: PI and FR4. PI(Polyimide) material offers excellent flexibility and high temperature resistance, making it ideal for applications involving continuous motion and high temperature environments. On the other hand, FR4 is a widely used and cost-effective substrate material. It has good mechanical strength and rigidity, ensuring durability under various operating conditions. Manufacturers can choose the material that best suits their specific requirements and design constraints.

The application-specific features of Capel’s double-sided PCBs make them ideal for infrared analyzer equipment. The analytical functions of these medical devices require the highest accuracy and precision. With the increasing demand for portable and user-friendly medical devices, infrared analyzers have become an indispensable tool in the healthcare industry. These devices facilitate non-invasive diagnosis and monitoring of various medical conditions, providing healthcare professionals with accurate and reliable results.

Capel’s double-sided PCBs have been successfully integrated into numerous infrared analyzer devices, providing manufacturers with a reliable solution and enhancing the performance of their medical devices. Its combination of advanced technology, flexibility and high-quality features ensures the accuracy and longevity of the infrared analyzer.

Capel’s gold-immersion double-sided PCBs offer a unique reliability solution for infrared analyzer medical device manufacturers. Its combination of customizability, advanced technology, and high-quality features make it ideal for enhancing the performance and reliability of medical devices. With their outstanding properties such as flexibility, tight tolerances, corrosion resistance and flame resistance, Capel’s double-sided PCBs provide manufacturers with the confidence and assurance they need to develop best-in-class infrared analyzers.

Post time: Sep-06-2023

Back